White Overture PETG poor performance advice and alternatives?

So far I've had really good success printing Hatchbox PETG. I've got the settings dialed and I have great prints with smooth walls, sharp corners, decent bridges and only a little whispy stringing.

For my current project I wanted to print in white PETG, which is unavailable from Hatchbox. I'd buy prussament, but it's hard to justify the cost (especially with shipping). Instead I bought a roll of white Overture PETG (and one of red). So far I used about 250 g just getting it to print at all. So far here's the critical parameters I've settled on:

nozzle: 260

cooling: max 30% at layer 5, 50% bridges

bed: 85

extrusion multiplier: 1.07 (used a micrometer)

max volumetric speed: 5 mm^3/s

retraction: 0.6 mm

lift z: 0.4 mm

first layer: 0.2 for 0.15 mm and 0.3 for 0.2 mm layers, always 10 mm/s

If I lower the temperatures at all I can't get the first layer to stay down. Also, I've got to run the live z a little lower (about 0.02-3 mm) to get it to stay down. This causes nozzle blobs, so I often have to pause and clean them before they fall off and ruin the first layer. On overhanging corners I get signs of overheating, but again if I lower the temperature the interlayer adhesion suffers badly. To top it off vertical walls look horrible, like there's layer shifting.

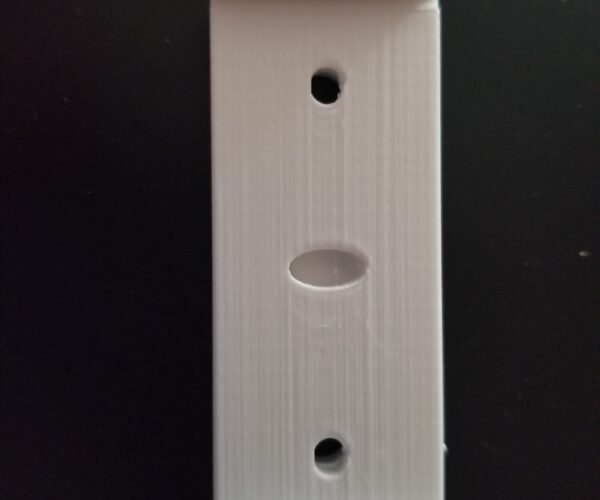

With Hatchbox I don't have any of these issues, I run it at 250 C nozzle, more retraction and much much faster print speeds. I've fully dried the overture right before use (140 F for 14 hours) and print from a drybox (big bag of fresh dessicant with each roll change, humidity holds at < 15%). The photos below green is Hatchbox, white is Overture, you can see the quality of walls with each.

I'm at wit's end. Overture gets good reviews overall, so if there's something I'm missing or some advice I'd love to hear it. If someone's had success with another brand of white PETG I'd like to hear that too, I don't want to be wasteful and buy more unusable filament.

Best Answer by FoxRun3D:

I've used Overture's black, blue, orange, red, gray and green PETG, and of course white. I don't have it right now (using some Sunlu, which I do NOT recommend) but I don't recall having issues with it.

Looks like you've looked in the right places and done the right thing. Honestly, at this point I'd just add this to the long list of 3D printing mysteries that make it more art than science and just write off the $25 for the spool. Life's too precious to waste it on chasing this down. The next spool of Overture PETG might very well be perfectly fine. In my case I actually had the opposite experience to yours. Never had luck with Hatchbox. Why, I don't know and truthfully don't care. Just stick with what works for you, and you'll be fine.

Overture PETG has become my go-to material for now, and I haven't been disappointed. My settings are (using your list of parameters):

nozzle: 230

cooling: min 30 max 50% at layer, 50% bridges, disabled for first 3 layers.

bed: 85/90

extrusion multiplier: 1.0

max volumetric speed: 8 mm^3/s

retraction: 1.4 mm

lift z: 0.2 mm

first layer: 0.2 for all layer heights, 20 mm/s

I believe it's pretty much the generic PETG profile, with a couple of changes.

Are you experiencing the same issues with the red PETG?

Also, you said you don't get the first layer to stay down and your nozzle seems to dig into the filament. That speaks for some serious adhesion problem. What sheet are you using, and how are you treating it? Live Z properly adjusted with PETG filament?

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Re: Adhesion

Yes, first layer adhesion is abysmal. I've tried smooth PEI with glue stick, Windex, cleaned with IPA, cleaned with Dawn, cleaned with acetone. Only with the really clean soap and acetone did I get it to stick enough to do live z. I also tried my textured sheet and that was a complete fail. The best I've found is the satin sheet, cleaned each time with Dawn, rinsed really well then allowed to drip dry. If I try to print without a full wash I see an image of the previous print in the first layer, like the filament is leaving a film behind. I've never had this before.

I have tried the red yet, still trying to figure out the white. It looks like your profile is the generic PETG, but a little cooler and more retraction. When I tried those sorts of temps it was instant spaghetti. Have you used the white before? I'm wondering if it's particular to that color.

Oooh.... acetone ...

Is possible your sheet cleaned with acetone is toast. It sounds like you need to go back to calibration though - if you can't get a live Z down, go back a step further and get the nozzle at least close to the bed. Then on to initial pinda calibration ... and then try live Z again.

Re: acetone

I'm sure that the smooth pei sheet is fine. Prusa even recommends occasional use on the smooth sheet, and I've only done it a couple times. It worked great afterward for hatchbox PLA and PETG (with a glue wipe).

It's not a calibration issue. Recently, with the same sheets and same PINDA and calibration setup I've successfully printed 3 colors of hatchbox PETG, several parts in Prusa PC/CF and a couple pla prints. I didn't have a single adhesion issue. At one point I thought it was a partial clog and did a few cold pulls, which came out clean. As far as the live z, with the white overture I've tried from barely squished to totally flattened way beyond too far and it just doesn't adhere, but I can go right back to where I had it and lay down perfect first layers with the other filaments.

I've used Overture's black, blue, orange, red, gray and green PETG, and of course white. I don't have it right now (using some Sunlu, which I do NOT recommend) but I don't recall having issues with it.

Looks like you've looked in the right places and done the right thing. Honestly, at this point I'd just add this to the long list of 3D printing mysteries that make it more art than science and just write off the $25 for the spool. Life's too precious to waste it on chasing this down. The next spool of Overture PETG might very well be perfectly fine. In my case I actually had the opposite experience to yours. Never had luck with Hatchbox. Why, I don't know and truthfully don't care. Just stick with what works for you, and you'll be fine.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: White Overture PETG poor performance advice and alternatives?

I've used Overture's black, blue, orange, red, gray and green PETG, and of course white. I don't have it right now (using some Sunlu, which I do NOT recommend) but I don't recall having issues with it.

Looks like you've looked in the right places and done the right thing. Honestly, at this point I'd just add this to the long list of 3D printing mysteries that make it more art than science and just write off the $25 for the spool. Life's too precious to waste it on chasing this down. The next spool of Overture PETG might very well be perfectly fine. In my case I actually had the opposite experience to yours. Never had luck with Hatchbox. Why, I don't know and truthfully don't care. Just stick with what works for you, and you'll be fine.

I thought variability in the diameter might be the problem, so I cut off about 1 m of filament and carefully measured it with my micrometer. I measured it at 20 places, about evenly spaced, and at each I measured twice at 90 deg from one another. Anyway, the smallest I got was 1.731 mm and the largest was 1.768 mm, so not perfect but well within the +/- 0.05 they claim.

I think you've nailed it with moving on. I give people that same advice about motorcycle tires. I'm going to try the red while I wait on a roll of eSun white and am optimistic that it'll be a good roll.

Mystery spools

I've got a mystery spool that won't stick to any other filament. Was supposed to be transparent red from Amazon Basics. Is white, whatever it is, prints at ASA temps fine, but melts like PLA at PETG temps. It's just occupying space on my table saw.

RE: White Overture PETG poor performance advice and alternatives?

White vs transparent red ... sure, I can see how they might have mixed that up 😬 Like earlier this week, my Amazon delivery of two smart plugs arrived - but instead contained a bottle of homeopathic baby drops...

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Cleaning once with acetone will not make your sheet toast unless you use steel wool or an abrasive.

I would concur that you need to adjust your Z.

It could also be a mystery filmant. It won't stick without the right settings.

Is possible your sheet cleaned with acetone is toast. It sounds like you need to go back to calibration though - if you can't get a live Z down, go back a step further and get the nozzle at least close to the bed. Then on to initial pinda calibration ... and then try live Z again.

--------------------

Chuck H

3D Printer Review Blog

RE: White Overture PETG poor performance advice and alternatives?

It's not my first layer/z that's the issue. I just did a couple calibration prints with the red Overture using the default generic settings in PrusaSlicer. It printed great. The first meter of filament was +/-0.02 mm in diameter. Extrusion multiplier was 1.006, no adhesion issues with the first layer or interlayer. For reference, once I put my liveZ back to my normal setting I got a first layer thickness of 0.201 when set to o.20 and excellent surface finish, which accounting for the slight ridges between lines is pretty great.

It's just a weird roll. It prints just like the nylon I've used in terms of temp and adhesion. So far the red hasn't given me a single issue and behaves exactly as I would expect PETG, so I will probably buy Overture again if I needed a color that was unavailable from HatchBox.

Cleaning once with acetone will not make your sheet toast unless you use steel wool or an abrasive.

I would concur that you need to adjust your Z.

It could also be a mystery filmant. It won't stick without the right settings.

Is possible your sheet cleaned with acetone is toast. It sounds like you need to go back to calibration though - if you can't get a live Z down, go back a step further and get the nozzle at least close to the bed. Then on to initial pinda calibration ... and then try live Z again.

@ktm1090

You should consider posting a Zipped UP .3mf project file exported from Prusa slicer, so we can take a look at the model specifically with the settings you are trying to slice with. the forums will not accept the file if it's not zipped, and it should be one of the files your having a problem with.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: White Overture PETG poor performance advice and alternatives?

I would bet you received either a bad or mis-labeled roll of filament.

I’ve printed a fair amount of Overture PETG in white, black, rock-white, green, magenta, transparent red, and transparent blue, using the textured print surface and have never had the adhesion issues you’re seeing.

I typically print a 0.2 mm first layer @ 235/85 and remaining layers @ 235-240/90 with very little stringing and zero adhesion issues. Most of what I print are functional parts at either 0.2 mm layer height or, more often 0.3 mm Draft setting which is faster and generally suits my needs.

Most colors print fine at the 240 temp with good layer-to-layer adhesion and little stringing. The transparent filaments like the lower 235 temp to reduce stringing but still provide solid prints.

The only color I had some issues with was the magenta which needed to print slower and at lower temps. For some reason this material is a bit “gooey” and it took some time to sort it out.

Be sure you’re followed the great advice posted by many here regarding cleaning your build plate with plenty of hot hot water, Dawn dish detergent, and a semi abrasive “scotch-brite “ type sponge. Unquestionably THE best piece of advice I can pass along.

I would not hesitate to recommend the Overture PETG. Obviously, ymmv. Best of luck.

RE: example .3mf

Here's a print that's giving me fits. I finally got it to print last night. For this one the first layer wasn't a problem, it adhered fine with my settings. Later in the print the filament would either stop extruding or drop a blob and cause a crash. In the picture of one of the finished parts you can see how grossly uneven the layers are.

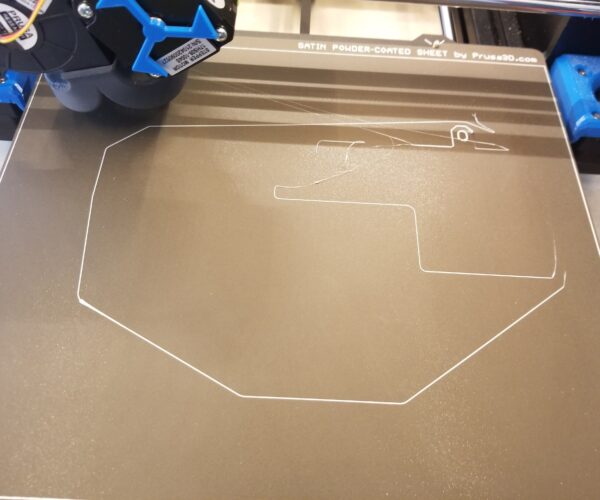

I've also included a picture of an attempt from this morning. I tried 4 times to get the first layer down. It would get part way through then the extrusion would get really thin and not adhere. I tried a couple cold pulls and got nothing. I was able to push the cleaning filament through with little resistance, so it's not likely a clog. That same print is running now with no issues for the first couple layers on this attempt.

Since the diameter is decent, it's like the material is changing properties as it goes along. Some sections flow better than others. Or my extruder just hates this color for some reason.

RE: White Overture PETG poor performance advice and alternatives?

Overture has a pretty good warrantee program. You might want to contact them if you still have the receipt.

RE: White Overture PETG poor performance advice and alternatives?

@swiss_cheese:

I have seen the magic you work and am daily gobsmacked by your talents.

I am switching to Hatchbox for all future PETG needs.

Thank you for the benefit of your wisdom and experience. 🙏🏻

RE: White Overture PETG poor performance advice and alternatives?

Although not ideal, the settings work. I am pretty sure this is a bad roll of filament. I have had them from several manufacturers including Overture and Hatchbox.

--------------------

Chuck H

3D Printer Review Blog

RE: White Overture PETG poor performance advice and alternatives?

You might want to contact them if you still have the receipt.

Or if you ordered on Amazon, just return it. I've done that for a couple of bad spools.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: White Overture PETG poor performance advice and alternatives?

Ditto.

You might want to contact them if you still have the receipt.

Or if you ordered on Amazon, just return it. I've done that for a couple of bad spools.

--------------------

Chuck H

3D Printer Review Blog