Which material do I have to use to print this wing??

Good morning

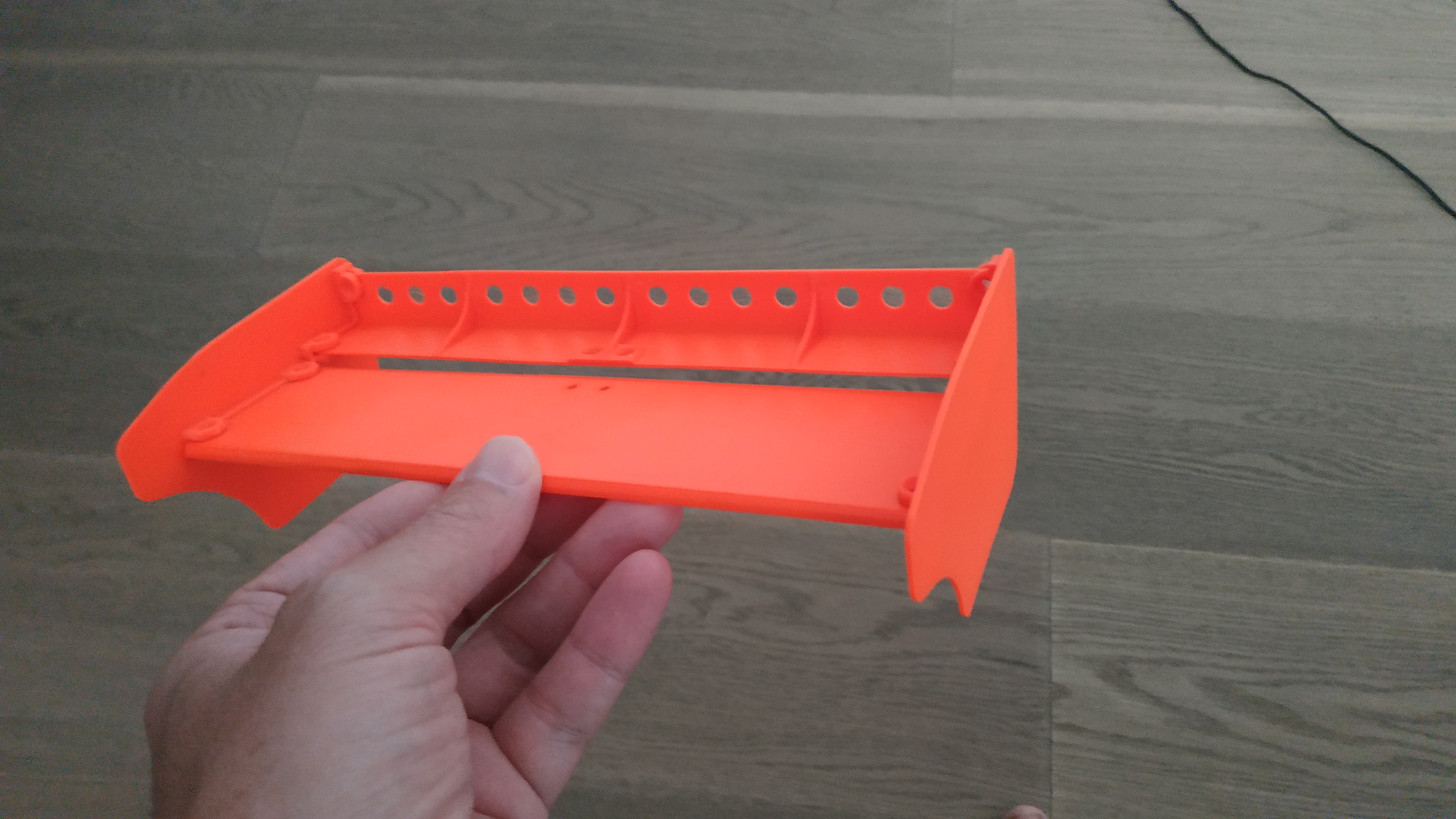

I'm struggeling to choose the right material to print this proto wing for my RC car.

I made my first print by using PETG but it brokes after few laps without any crash. It brokes where the wing is screwed to the wing mount.

The wing has to be flexible but not too much otherwise it will be bended by the air flow (RC cars reach 60 Km/h).

The wing thickness is about 1.3mm (I don't want to increase it because of weight problems).

The flexibility I've reached by using PETG is quite ok but the wing is too fragile and probably the bonding between the filaments is too weak for this application.

I've got Flexi wire (Flexfill 98A made by Fillamentum) but it's too soft but I've seen that the filaments bonding is much higher and I can bend a 1.5mm plate without broken it. If I do the same with PETG I broke it easily especially in the filaments direction.

I don't which material I should buy to get a wing which can survive for few hours and let me understand the best design.

Thanks in advance for your help and advices.

Matteo

Re: Which material do I have to use to print this wing??

You could try Nylon (Polyamide) or Polycarbonate (from my research, PC-Max ist the best option)

Both materials are challenging to print, but should provide high strength and toughness.

I'd personally try Nylon or change the wing design to distribute the load better.

You could really print an actual wing instead of the flat plate, that should be aerodynamically better and with the thicker cross-secition it should be stronger as well. Layer adhesion will be important though when printig it upright

Re: Which material do I have to use to print this wing??

Thank you for your reply.

I've had a look to the PC-Max data sheet and it looks a good option. Thanks.

I don't know much about Nylon: does it has a good filament bonding strenght?

I would like to achive a good compromise between strenght and flexibility because when the car crash the wing can be really stressed and bended heavily.

I think that the wing supplied in the car assembly kit is made by PA: does it has a good strenght and flex? Does it also has a good filaments bonding strenght?

What about the anneiling ? I've read about it for PC printed parts but I don't know if it can help also for Nylon.

Thanks

Matteo

Re: Which material do I have to use to print this wing??

Nylon is very strong and tough, i.e. it's very hard to break and has very high layer adhesion.

Polycarbonate should be stiffer and very strong as well. Technically maybe stronger than Nylon, but also stiffer, so it could still break more easily.

And while both materials are difficult to print, Nylon should still be easier.

The wing supplied with the kit is likely made from vaccum formed "Lexan", which is polycarbonate. If it's an injection molded part I'd guess that it's ABS. But both these production methods have different properties compared to fdm.

In your case I think it's a good opportunity to start learning to print Nylon.

Disclaimer: I have not yet printed Nylon or PC myself, but am getting ready to try it soon.

Cheers and good luck!

Re: Which material do I have to use to print this wing??

Thank you very much for your precious help!

Matteo

Re: Which material do I have to use to print this wing??

I agree with georg.s2. IMO Nylon would be the best material to try first.

A few things (if you aren't aware already):

That's "MISTER Old Fart" to you!

Re: Which material do I have to use to print this wing??

Thank you RufusClupea!

I'm checking the Taulman products in order to choose the best for my application.

Is the enclosure mandatory in order to print Nylon ?

Thanks!

Cheers

Matteo

Re: Which material do I have to use to print this wing??

Is the enclosure mandatory in order to print Nylon ?

Let's say it's highly recommended by persons who know far more/better than I.

Enclosures don't have to be Taj Mahals--a corrugated box would do in a pinch. There are all kinds of designs at all kinds of levels.

My best advice is to read up/watch the references in the link I posted previously, then if you decide to build one, review a bunch via google.

That's "MISTER Old Fart" to you!

Re: Which material do I have to use to print this wing??

Did you calibrate your extruder (extrusion multiplier) for that material? Mechanical performance drops a lot if under extrusion.

More 3D print friendly material would be ColorFabb XT or FormFutura TitanX. No absolute need for enclosure and good bonding.

The best would effectively be Nylon. Polycarbonate is more resistant to high strength but less resistant to deformation than Nylon. I have no experience with Nylon because it seems to me a lot of precaution to handle (plate adhesion, hygroscopic). I prefer for now to stay away from it as I don't have absolute need of it.

I would also add some ribs were it broke.

Re: Which material do I have to use to print this wing??

Hi Ron

Thanks for your post.

I'm printing with a Prusa MK3 and I've got no experience with 3D printing.

I'm using the Prusa Control software to slice my parts.

This software has default settings for the most common materials such as PLA, ABS, Flex materials and so on.

So I'm not "playing " with the printer setting right now because I do not have any experience yet.

The PETG wing that I've printed was made with the default settings as well.

I sincerly don't know nothing about the "extrusion multiplier"...need to check what it is!

Regards

Matteo

Re: Which material do I have to use to print this wing??

Shouldn’t a wing bend as less as possible to keep the aerodynamics on higher speeds ?

That would speak against nylon or pc because they bend if you apply force.

As already mentioned Colorfabb XT is also very tough, faaar more easy to print than nylon or pc and it won’t bend (until it cracks).

Re: Which material do I have to use to print this wing??

This is a model the prime factor in my experience is crash damage. Where flexibility will be a benefit

However I suspect the model would benefit from additional reinforcement around the mountings

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Which material do I have to use to print this wing??

I post here a link to a video where you can see some RC car crashes:

Let me say that the wing cannot be too much tough otherwise it became " fragile and brittle".

It should be a compromise between strenght and flex.

RC off road cars don't reach very high speed (max around 60Km/h) so aerodinamics is important but not too much!

On road RC cars are much faster and aerodinamics is the key!

The wing design will be improved but in my opinion I have to choose the right material.

I'm checking the ColorFabb products. Thanks!

Matteo

Re: Which material do I have to use to print this wing??

I sincerly don't know nothing about the "extrusion multiplier"...need to check what it is!

You can see here https://mattshub.com/2017/04/19/extruder-calibration/ what is it. But you don't have to send a M92 and M500 command. It explains you a method. If you tell the printer to make a 0.45 width wall and you have only 0.42, you under-extrude.

As a beginner (beginner+ now) you could use Slic3r PE. It permits you to change the Extrusion multiplier in filament settings. I never used Prusa Control although I installed when it was released. Perhaps you can do it too with that software. If you measure 0.43 instead of 0.45, you set 0.45/0.43=1.05 in extrusion multiplier.

I guess how the layers are oriented. It is the best for printing but not to resist to the forces that broke the part. And i suspect that changing the orientation will make the part hard to print.

If you try ColorFabb XT, don't be afraid to push the fan to 100%.

Re: Which material do I have to use to print this wing??

Thank you Ron!

Very helpfull info!

Cheers

Matteo

Re: Which material do I have to use to print this wing??

This is a cool enclosure project for the MK3 that also shows the use of pocket photo studio in fabric that is both cheap and quick I wish I had known about it when I was having problems with Taulman 910 nylon http://taulman3d.com/alloy-910-spec.html with my big Delta printer (Rostock Max V2.5 from SeeMeCNC)

https://www.prusaprinters.org/cheap-simple-3d-printer-enclosure/#_ga=2.228246045.1829493153.1537402693-1444735114.1531445689&_gac=1.149298628.1537620320.Cj0KCQjwrZLdBRCmARIsAFBZllEWvLqlMjoiF8C6veDI7wDGIbr7C-6SG_vHzdOcSGfe6dAQtFpHsioaAgB0EALw_wcB

[youtube] https://www.youtube.com/embed/oS7ZtBNh2hE [/youtube]