Vase Mode with PETG Delaminates?

I tried to print a vase mode item with a generic petg, I tried 4 different settings

- Default Fan on settings

- first layer at 230/85 then 215/90

- first layer at 230/85 then 245/90

- Fan always off settings

- first layer at 230/85 then 215/90

- first layer at 230/85 then 245/90

Temperature adjustment for both fan on/off settings felt no improvement as if there's around 5% layer adhesion improvement only. With fan settings at default to "generic petg" stock setting, the printed vase object delaminates rather easily when I tried to grab by the thin wall to get the thing off of the textured surface, by weight maybe it will delaminates around 50-100gram of pulling force (I don't know).

With fan off settings, still delaminates but takes a bit extra force perhaps 100-200grams of pulling force?

I am seeking some kind of an explanation whether or not petg would be fitting to be used in vase mode or not. I do however thought of increasing the extrusion width to maybe 0.60 or 0.80mm, but not sure if this will be advisable

RE: Vase Mode with PETG Delaminates?

Um - what PETG specs a print temp so low (the 215 numbers)? At 245, most PETG should laminate well. But depending on room ambient and print speed, higher temps might be required, but so may lower print temps for other reasons.

Without a ZIPPED copy of the project to review - anything else is guessing.

RE: Vase Mode with PETG Delaminates?

@tim-2

it is 200-240c/75-85c. All the other settings not mentioned above are all referenced to prusa's stock settings

RE: Vase Mode with PETG Delaminates?

@asraff is this Sunlu by any chance? Do a temperature tower to see what temperature works best on your printer. Labels can be wrong (see Sunlu) and certainly aren't written for the Mk3 specifically.

Much will depend on your overall setting. Save your part and settings as a 3MF project file, zip it up, and attach it to a reply here for better suggestions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Vase Mode with PETG Delaminates?

@bobstro

I don't think it is sunlu brand either, it doesn't even have a name. Been using this generic no-name brand filaments for years and it's just that I never tried to print things in vase mode especially with petg materials recently.

I print at 215c because it produces very fine wisps/strings that is similar or thinner than spider thread when burnt, it doesn't leave a blobby mark on the surface. The surface finish is also great in overall.

Printing at 245, the surface became rougher and even more strings can be seen, they leave blobby finish when burnt to get rid of them.

Layer adhesion on normal parts print with petg at 215c are okay.

Bellow is the 3mf file requested

RE: Vase Mode with PETG Delaminates?

Fan off - and probably change perimeter width to 0.6 to get a higher nozzle pressure over instead of 0.45; but still not a lot of thermal mass to cause the filament layers to fuse. So slowing the print way down (15 mm/s) would be the other option along with wider walls.

RE: Vase Mode with PETG Delaminates?

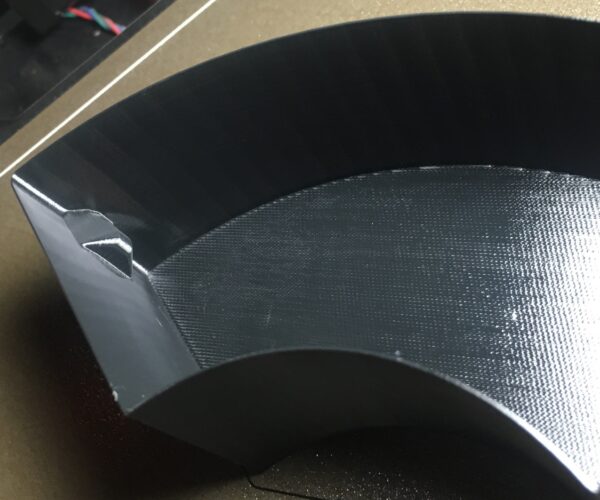

I printed 2 of the same thing

I forgot to turn off fan but I did at 6mm left to completion, temperature is 230>215c/85>90, external perimeter 0.60mm. The layer adhesion was a bit better but fan always on at least 30% made it worst, on the layers that fan turned off, they adhere bit better compared to fan turned on.

Another printed with similar setting as the above, with 230>240/85>90c, fan off all the way and external perimeter speed of 15mm/s. Surface finish is quite rough, there's a part that at the bottom of the external perimeter kind of shrank for the first 5mm after the bottom layers has been laid out. I slowly pulled the parts by grabbing the thin wall, the ones that broke easily is right after the bottom solid layers, the area where the external perimeter shrank. I tried to pull apart the upper 'stable straight' layers, they had more resistance compared to 215c, but to me still kind of easily pulled apart in overall.

all other settings not mentioned above are default stock

RE: Vase Mode with PETG Delaminates?

@asraff

You're going to have to forget about 215 for this type of part. Also - have you looked up what the sheer strength of PETG is when it is only a fraction of a mm thick? You might consider what you are trying to do (or the strength you want) is not possible.

RE: Vase Mode with PETG Delaminates?

@asraff

You're going to have to forget about 215 for this type of part. Also - have you looked up what the sheer strength of PETG is when it is only a fraction of a mm thick? You might consider what you are trying to do (or the strength you want) is not possible.

I understand about the 215c, just a test and comparison. As for my expectation, I thought that it may behave almost similar to how pla and tpu in vase mode would be, though my experience with vase mode is only scratching the surface and more than 4 years ago. While I never tried the layer adhesion strength in pla but the that pla vase somewhat lasts for a while (it wasn't mine).

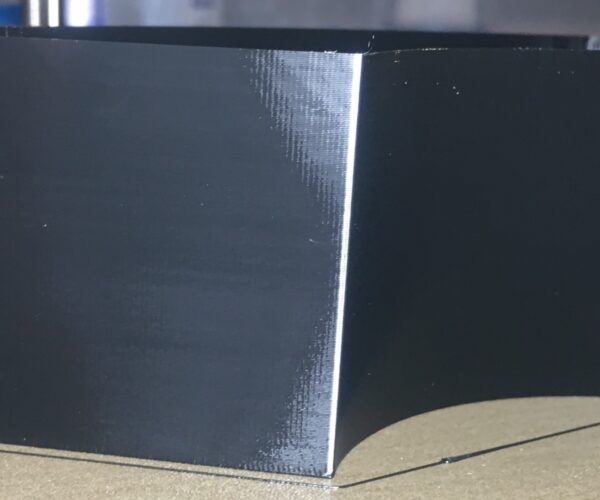

This is the object above in which I wanted to 'hack' vase mode for something else other than just 'ornament'.

I don't think I'm going back to pla either since pla in filament form easily got brittle over time, "shelf life"?

RE: Vase Mode with PETG Delaminates?

PETG at 215 is brittle and will fall into strings when you pull it off the plate. Print it at 230 min, 250 should work for good lamination.

RE: Vase Mode with PETG Delaminates?

@dan-rogers

I assume you're recommending me to print another one with 250c? Any advice on other settings?

RE: Vase Mode with PETG Delaminates?

@asraff

I would never attempt something like that in vase mode. Just too fragile, regardless of materials. But PETG is probably the worst for interlayer adhesion: it needs temp and pressure to weld properly, making vase mode even more of an issue. You can try 1 mm vase perimeters... a 0.4 nozzle will do that; but at that point two .45's is better.

I don't have any other suggestions at this point.

RE: Vase Mode with PETG Delaminates?

@asraff

I would never attempt something like that in vase mode. Just too fragile, regardless of materials. But PETG is probably the worst for interlayer adhesion: it needs temp and pressure to weld properly, making vase mode even more of an issue. You can try 1 mm vase perimeters... a 0.4 nozzle will do that; but at that point two .45's is better.

I don't have any other suggestions at this point.

I see, I also thought that, even if vase mode wouldn't going to work no matter what settings, making it hollow, inside, no top, no infill, 3 perimeters would make the best alternatives for layer adhesion? But with the cost of more plastic usage.

The settings just now would be similar to most spool storage box that has 1-2mm wall thickness is it?

RE: Vase Mode with PETG Delaminates?

It is printable in vase mode, but you won't get the shape in your design - you'll get a quarter circle planter, with good holding strength, and a strange little doo-hickie near the top where that useless hole is. Choose the generic PETG or Prusament PETg profile set vase mode accept defaults. You get a quarter circle flower pot, and I expect the little hole near the top makes a mess.

RE: Vase Mode with PETG Delaminates?

@asraff

This is your model printed with PETG, it printed flawlessly in 1hour and 28min in vase mode, exactly as you designed it, not a strand out of place no stringing, no warping ,no sagging, no nothing wrong at all, great design (Freaking perfect).

Your profile sucked, and if you don't know what kinda material your printing it's no wonder you can't print it. do not waste your $$$ and time on generic (your not even sure what it is filament) and expect to have control over your result. furthermore don't expect others to be able to help when you can't provide them with proper information to do so, whatever that stuff is throw it in the trash and don't buy it again, you have saved yourself nothing.

These are the settings I used to accommodate a known PETG, I don't expect them to work with whatever filament your using, however you can give it a go, or at least learn from them.

Swisses own.3mf

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: Vase Mode with PETG Delaminates?

Oh, is that what it is? A spool storage box - neat. Now the little hinge hole makes sense.

Throw a cool cover (like nuka cola top) on it and those would sell on etsy if you can get the right audience.

RE: Vase Mode with PETG Delaminates?

@swiss_cheese

So Swiss -- how is the strength of your PETG build of that box? How badly does the drawer warp and flex if you were trying to open it? Will it stay together or will daily use cause the filament layers to separate? Almost everything I have ever printed in vase mode has been fragile - usable with caution and care - but not anything I'd put in utility service like that box. The exception was a small flower vase, but the design doubled up fins in a zig-zag to add rigidity.

Anyway - your print turned out so well - as designed - hoping you can comment on it's strength.

RE: Vase Mode with PETG Delaminates?

@swiss_cheese

Thank you for the feedback, but I still going to say the following and I mean no offense. The filament is a no-name brand filament that I have been using to print objects other than vase mode as I don't have much 'appetite' for printing vase object ornaments especially after I switched to PETG. I highly disagree with your sentence of

furthermore don't expect others to be able to help when you can't provide them with proper information to do so,

as they would be a sign to shoo away those who seeking support when they got into trouble for; not enough knowledge, not sure what information to provide. I think it is much more proper for someone who wanted to give support, asks for more information and pieces them together to become a more proper information. If still standing their ground like the quote above, please don't stress yourselves out to solve someone else's problem as soon as possible. This isn't a race. I mean no offense nor seeking any fights, this isn't the first time I'm getting similar replies in different form.

I inspected your profiles, the only difference I could spot is having a higher nozzle temperature of 235>252c. Unless, I'm not smart enough to spot anything else.

@dan-rogers, yes it is a spool storage box, this concept to reduce plastic usage requirement to print each section

RE: Vase Mode with PETG Delaminates?

@tim

The box is very flexible as you might expect it to be, if it were filled with small nuts, washers or even wire nuts I wouldn't expect it to maintain its shape. the layer adhesion is fine for this filament and can't be pulled apart just shy of using pliers or some mechanical force. if you pinch it along the layers you can cause them to separate, I actually preformed all these actions after you asked your questions. my evaluation is that it will not be suitable for prolonged use printed in vase mode out of PETG.

The Filament Whisperer

RE: Vase Mode with PETG Delaminates?

@asraff

None taken, and It was not my intention to shoo you away.

Good Luck,

Swiss_Cheese

The Filament Whisperer