Vase mode keeps failing around corners

Hi,

Been having big issues with this specific print, been trying to print after updating to the latest firmware (3.10) and it seems that since this changed, my vase prints suck.

I honestly have no idea what else I could do, I tried changing one setting at a time to see if something changes, and the best one I got is the one I attached the 3mf file and photos.

Do note, I attempted to use the exact same settings as the successful vase print I did prior to the upgrade using my 0.8mm nozzle however got the same results.

Redid the same print with the old model and it worked relatively well, see the attached pics. The two models aren't vastly different, I do suspect that perhaps the new model is too thin? Walls are 1.75mm.

Help ?

TestPrint

TestPrint

Thanks 🙂

Best Answer by bobstro:

I'm not set up with a 0.80mm nozzle at the moment, but ran off a proof of concept using a 0.40mm nozzle with 0.32mm layer heights and 0.8mm extrusion widths set to vase mode:

This shows how the wider extrusions can help avoid gaps between severely overhanging layers (to a point).

RE: Vase mode keeps failing around corners

IMO, the overhang angle is beyond what will print reliably. I forget if you can select 'add extra perimeters if needed" in a vase mode print. The pictures are helpful - > 45% overhang will create what you are seeing. If you try reducing layer height it might help - there needs to be a layer under the layer being extruded.

RE: Vase mode keeps failing around corners

@aye

Lowering the layer to height to 0.4 or even 0.35 will help, currently the angles of the model are to much for 0.55 layer height in vase mode.

Good Luck Swiss_Cheese

The Filament Whisperer

RE: Vase mode keeps failing around corners

If you're using a larger nozzle, you need to use much lower speeds as you increase extrusion width or height. Try slowing down the print 50% using the front knob and see if that helps. If so, you know slicer settings can help.

You can reliably print wider extrusions with quality nozzles. Try increasing your extrusion width along with slower speeds. 120% of your nozzle size is the typical recommendation for most cases, but with E3D nozzles, you are can print with extrusion widths of roughly 200% of nozzle size reliably. That will help with those gaps between extrusions that you're seeing near the top. Reduced layer heights can help if you get sagging, but the extrusion width addresses the gaps. It's a balancing act. Wider extrusions also make vase mode prints stronger.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Vase mode keeps failing around corners

As to why you are getting different results after the firmware update: How old was your previous firmware? There were changes to the handling of linear advance. Have you updated your filament settings as well?

It's worth pointing out that this model is not ideal for vase mode printing. You can get it to work, but the STL is designed with thicker walls for the protruding bits. A design optimized for vase mode would have a solid part (enclosed top to bottom) and let the slicer figure out the wall thicknesses.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Vase mode keeps failing around corners

I'm not set up with a 0.80mm nozzle at the moment, but ran off a proof of concept using a 0.40mm nozzle with 0.32mm layer heights and 0.8mm extrusion widths set to vase mode:

This shows how the wider extrusions can help avoid gaps between severely overhanging layers (to a point).

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Vase mode keeps failing around corners

I'm not set up with a 0.80mm nozzle at the moment, but ran off a proof of concept using a 0.40mm nozzle with 0.32mm layer heights and 0.8mm extrusion widths set to vase mode:

This shows how the wider extrusions can help avoid gaps between severely overhanging layers (to a point).

Thank you all very much!

I will give the extrusion widths a go at 150%.I'm using this nozzle (with generally, good results)

RE: Vase mode keeps failing around corners

If you're using a larger nozzle, you need to use much lower speeds as you increase extrusion width or height. Try slowing down the print 50% using the front knob and see if that helps. If so, you know slicer settings can help.

You can reliably print wider extrusions with quality nozzles. Try increasing your extrusion width along with slower speeds. 120% of your nozzle size is the typical recommendation for most cases, but with E3D nozzles, you are can print with extrusion widths of roughly 200% of nozzle size reliably. That will help with those gaps between extrusions that you're seeing near the top. Reduced layer heights can help if you get sagging, but the extrusion width addresses the gaps. It's a balancing act. Wider extrusions also make vase mode prints stronger.

To answer this, I have tried to print the entire model at 45% overnight before this happened, and it printed with the same faults, this is why I'm now only attempting to print parts of it.

RE: Vase mode keeps failing around corners

Thank you !

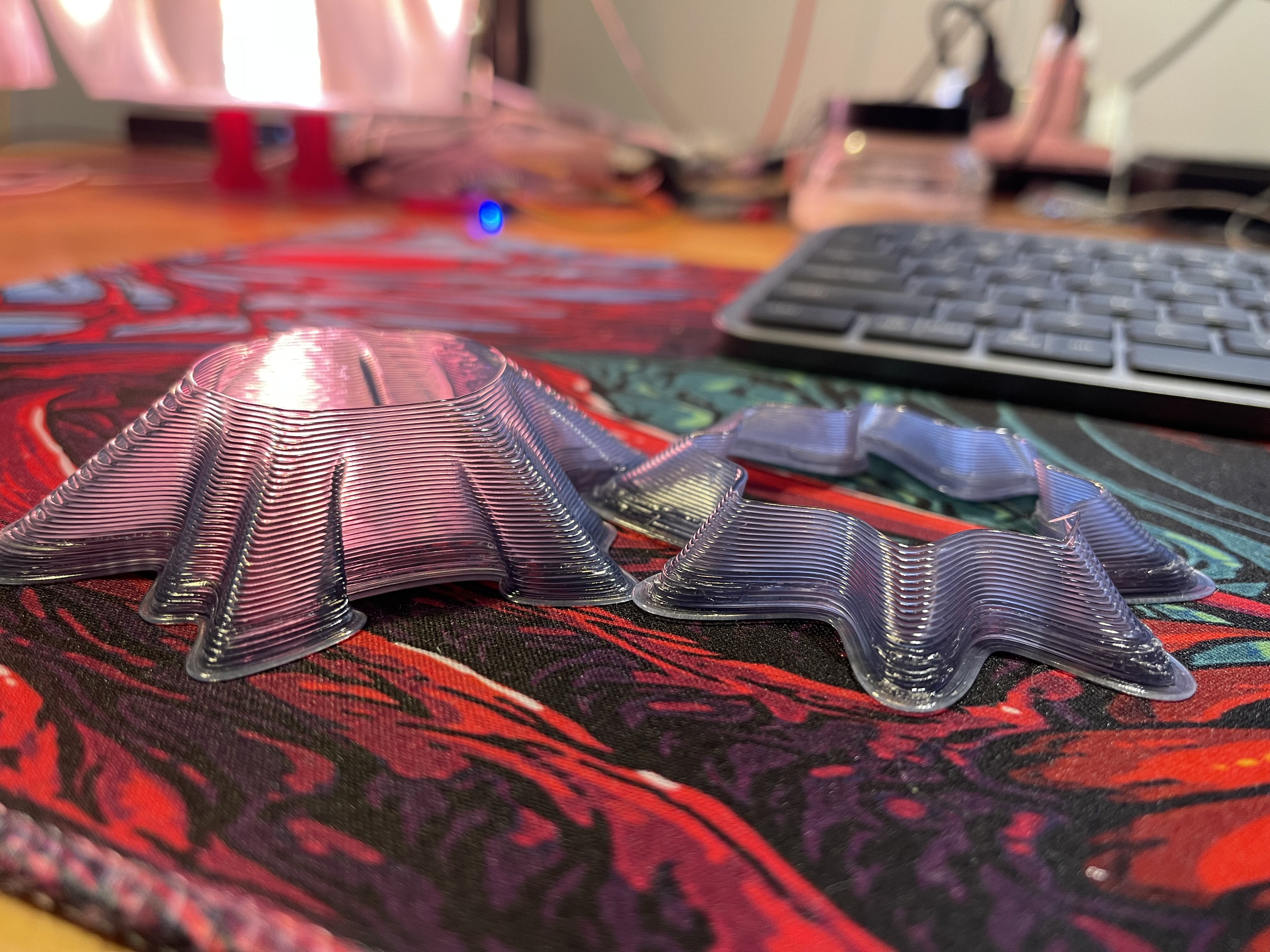

Right, thanks for the advice, it was the layer extrusion width + height, i went to 0.64mm height and 200% at 45% speed and it came out clearer, MUCH stronger and no faults (other than first layer, which I will fix). See below: