Unprintable!

I have a file which I am unable to print on my MK3 due to it causing crashes in the printer firmware (which is the latest (1st March) v3.6.0 binary). The crashes come relatively frequently and the printer is able to recover up to around the 34% complete mark when it tries a couple of times and then prompts me if I really want to try again: I do but it doesn't seem able to get any further, I end up back at the prompt after each re-start attempt.

This is sliced using slic3r to print in 0.05mm ultimate resolution in ABS (actually ASA with a bed temperature of 110C) with a brim. Slic3r is Prusa Edition 1.41.2 win64 (23 November last year).

The GCODE file is attached. I've tried re-arranging the parts that I am printing to lie at different angles on the heat bed before slicing and that does seem to make a difference, in that the frequent/recoverable crashes go away but the unrecoverable crash at the 34%-complete point remains.

Can anyone suggest a workaround, as I'd really like to get this 15 hour print out of the way?

Re: Unprintable!

Zip the STL ... it'll be more helpful, as will a photo of the furball.

And, if you have a MK3, turn off the filament sensor and try printing.

Re: Unprintable!

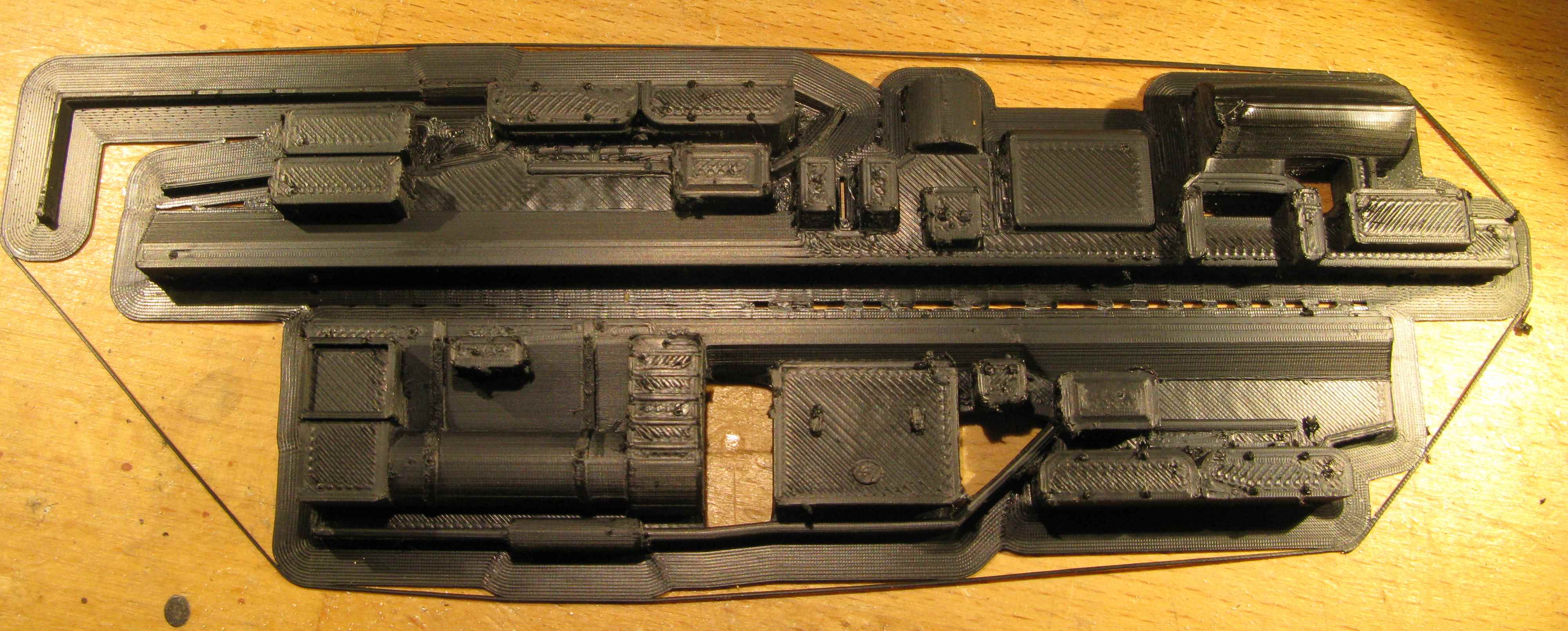

STL attached: the two parts in the STL file are split and then I align their flat edges with the heat plate, press "arrange" and that's it. I've just tried updating to slic3r Prusa Edition version 1.42.0-beta+win64 but, after re-slicing, the problem remains. Find here an [unlisted] YouTube video of the entire error/restart process:

Filament sensor shows up in the menu as [off] already (I've never touched the setting).

Re: Unprintable!

Are the corners of your part lifting from the bed? Hard to see in the video but it looks like it's always crashing after hitting the same part on the print, so I'm betting it's the nozzle hitting the part.

Have you verified your X and Y axes move freely by hand?

Re: Unprintable!

No, no lifting, and I've printed other parts similar to this (in some cases taking even longer), and in ASA, without issues over the last 6 months. Would nozzle contact really cause a SW crash in the printer?

Ref. X/Y axes, I can print other objects successfully, no crashes that I've noticed, so I don't believe the problem is mechanical, it seems likely to me that it is something to do with the GCODE at around 34% into the file, but I don't know what anomaly to look for.

Re: Unprintable!

IIRC the crash detection is based on motor current feedback; I'm assuming that means the threshold differs a bit depending on what the normal motor loading is (bearing smoothness, belt tension, etc)

In the interest of a workaround... what happens if you print in stealth mode or turn off crash detection? Both can be done from the settings menu.

Re: Unprintable!

Ah, OK, I was thinking of crash in terms of SW crash rather than in terms of mechanical crash :-).

That's a very useful workaround suggestion, I'll go fiddle with modes and report back.

Re: Unprintable!

The CRASH DETECTED warning may indicate one of your bearings are sticking. And to be honest, I have never seen a resume work well. If my printer stops for any reason, even power fail, I just stop the print. It could also be warpage causing the problem, especially with 0.05 mm layers. Any warp will cause too much extruder backpressure (no extrusion) and may even snag the nozzle, especially with the part complexity. If the adhesion is good the nozzle can drag the other axis a few steps, and the part is ruined anyway.

When you power off the printer, how easy is it to move the X and Y axis? They should glide smoothly and without any "bumps or snags" along the way.

An over tightened U bolt on the Y-Axis, and odd tolerance buildup in the X-Axis can cause the bearings to drag on the rods and cause problems. If the X-Axis is snagging, some folk find loosening the screws that clamp the bearings in helps.

Re: Unprintable!

The CRASH DETECTED warning may indicate one of your bearings are sticking. And to be honest, I have never seen a resume work well. If my printer stops for any reason, even power fail, I just stop the print. It could also be warpage causing the problem, especially with 0.05 mm layers. Any warp will cause too much extruder backpressure (no extrusion) and may even snag the nozzle, especially with the part complexity. If the adhesion is good the nozzle can drag the other axis a few steps, and the part is ruined anyway.

When you power off the printer, how easy is it to move the X and Y axis? They should glide smoothly and without any "bumps or snags" along the way.

An over tightened U bolt on the Y-Axis, and odd tolerance buildup in the X-Axis can cause the bearings to drag on the rods and cause problems. If the X-Axis is snagging, some folk find loosening the screws that clamp the bearings in helps.

To the OP - if this is the problem, it will manifest as layer shifts in the print that was run with detection turned off (since it sounds like you may have already started that before this post happened)

Re: Unprintable!

Stealth mode was a good workaround: 14 hours and the print is completed to a sufficient quality for my purposes. Looking around it, there was some rising of edges, though curiously not in the area where it seemed to be getting a crash. Here's a view of one of the worst parts: the quarter-circle feature visible on the right is NOT in the original STL.

The X/Y axes seem, to me, to be free, but it is possible there's some slight sticking around the middle of the throw of the Y axis so I might try loosening the U bolts very slightly just in case.

Thanks for all your help guys, obviously tuning of the machine for such high resolutions is vital.

Re: Unprintable!

Ouch. Is this typical quality you get from your 0.05mm layer prints?

That does not look very pleasing. With a surface finis like that you might very well lose any advantage you got from the thin layers. Can you post pictures from a little bigger distance, showing more of the print?

Re: Unprintable!

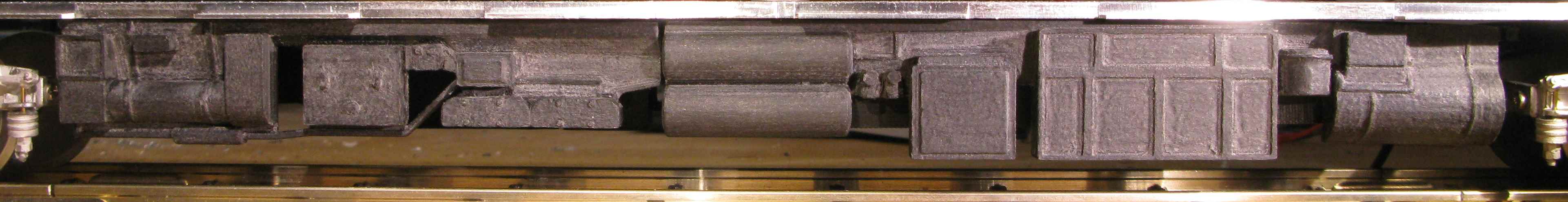

It's usually much better than that, see below for instance another print at 0.05 mm resolution in ASA with zero finishing. What matters to me in the case of the problematic print is not the surface you see in that photograph but the one looking down from above and that's fine for my purposes: there are some gentle slopes where I want to avoid excessive stepping. I'll post more pictures later when I get home.

Re: Unprintable!

Why are you using an ABS like material?

Re: Unprintable!

Ah, because I need a UV safe material as these parts will be used outdoors, hence ASA.

Re: Unprintable!

Someone else was making a weather product and did some tests in a hospital OR where he had access to some killer UV lamps ... the results were not what I'd call scientific, but very interesting as to which plastics fared best.

Re: Unprintable!

I'd be interested in a link to that, will Google search.

That said, the only issue I've had with ASA, aside from this one, that can't be solved as part of the inevitable finishing process is some warping on the base of tall objects, see discussion here, which improves acceptably if I turn the heat-bed temperature up.

Of course, if there is tuning I can do to the printer itself, that will help all my prints.

Re: Unprintable!

Re: Unprintable!

Thanks for that; fascinating though, as you say, only a simple test. I wouldn't be concerned too much with ASA changing colour, the bits of my model where colour matters will be painted, it's losing structural strength I'm more concerned about. I'm using "natural" ASA, so I'd hope that loss of pigmentation shouldn't be an issue.

Bleurgh, it's too late now, I'm part way through all my final prints, guess I'll be the next experiment in how proof ASA is to UV.

Thanks for all your help guys!