two materials one extruder?

hi there

I was wondering if anyone has successfully printed something from two different materials (not colours, e.g. PETG and Flex) on a single-extruder printer?

In theory it should be possible - right? Heard about virtual extruders a while back, but cannot recall where. Question is, is it worth the hassle and how would I go about it in PrusaSlicer?

Are there any tutorials or examples I could learn from? All I found refers to a colour change but in this case all filaments used are the same Material with identical properties - so the printer settings remain unchanged after the change.

Any insights would be much appreciated.

RE: two materials one extruder?

hi there

I was wondering if anyone has successfully printed something from two different materials (not colours, e.g. PETG and Flex) on a single-extruder printer?

In theory it should be possible - right? Heard about virtual extruders a while back, but cannot recall where. Question is, is it worth the hassle and how would I go about it in PrusaSlicer?

Are there any tutorials or examples I could learn from? All I found refers to a colour change but in this case all filaments used are the same Material with identical properties - so the printer settings remain unchanged after the change.Any insights would be much appreciated.

The problem with MM printing with different filaments is the missing temperature control. Therefore nikolai has written a PP script that adjusts the temperature at each filament change to achieve better results. I have been using it for a while and print with PETG/ABS combinations.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: two materials one extruder?

Thanks for the link. I briefly scrolled through the discussion but it looks to me like this "only" changes the temperature. With a combination of PETFG and Flex, for example, you would also need to adjust other parameters in respect to the different properties of the filaments.

That said, it sure is impressive what can be done. I'll investigate this further when I've some free time again. For my specific print I am looking at one single change of materials: bottom few layers are Flex, rest is PETG.

This can probably even be done by modifying the gcode manually but I never looked at the syntax in any detail. Might be the easier way to go for an individual project. I was hoping for something like adding a virtual extruder with a separate filament setting and do a "material change" similar to the colour change function in PrusaSlicer. Anyways, thanks for the tipp, if I get something viable I'll post it here.

RE: two materials one extruder?

I do it all the time, but I don't use an MMU2. I do it manually. It's completely doable. you do need a great understanding of your tool and of the materials though.

The Filament Whisperer

RE: two materials one extruder?

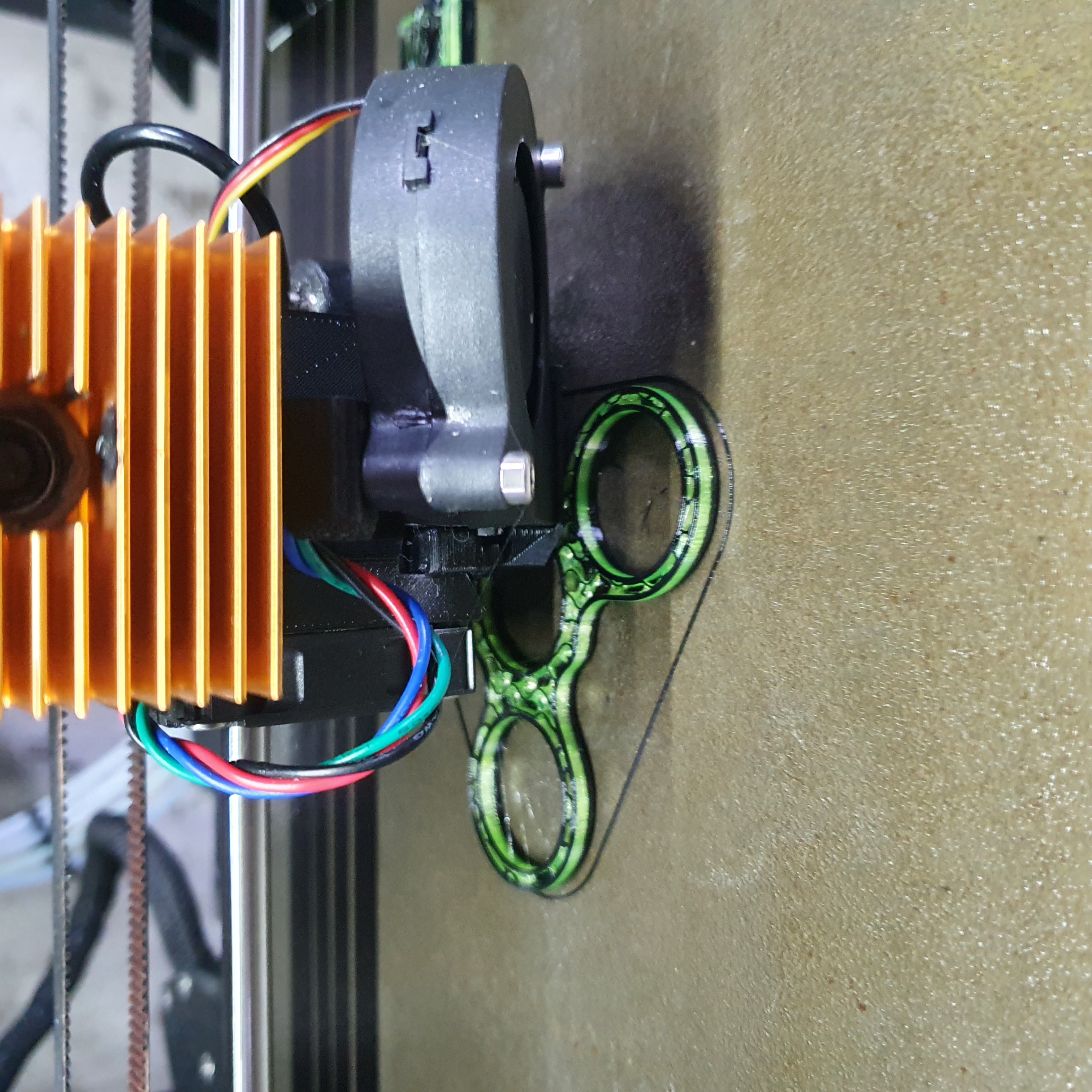

I've already printed TPU (black) + PETG (neon green) using the MMU2S. This combination works great.

Looks cool. Forgot to mention that I do not (yet) have the MMU upgrade on my printer. Did not really have a need for my purposes until now.

But could you maybe go into a little more detail regarding the settings? Are there any changes made during the print to extruder temperature, volumentric speed, retraction, etc? Or do you use the same settings for both materials?

RE: two materials one extruder?

It can be done, it's a real hassle changing temperatures - the quick and dirty way is to change them manually on the printer BTW but if there are several changes it soon gets tedious.

For my specific print I am looking at one single change of materials: bottom few layers are Flex, rest is PETG.

It may be easier to print two parts and join them later - add some keyways for alignment.

Don't be fooled into buying the MMU to do this, it doesn't do it well so you have to monitor the print and print times can grow very long if there are waits for temperature changes on every layer.

Cheerio,

RE: two materials one extruder?

@diem

Yeah, also thought about just gluing the two halves together. Might indeed be the simplest way to go here - would even go for a snap-fit or something.

But would have been cool to print in one go, for sure.

RE: two materials one extruder?

Many flexibles including NinjaTek Ninjaflex print very well in the 230 to 240 range, so do many brands of PETG, you can set the temp to change with layer heights just like with a temp tower, however you may find it easier to use FLEX, PETG's and PLA's that fall into a similar temperature range. then just do a color change at the layer you want/need. if your doing multi part prints you can even specify parts. the only thing I change is the print speed when doing combos I slow the TPU parts down, no temp changes.

The Filament Whisperer