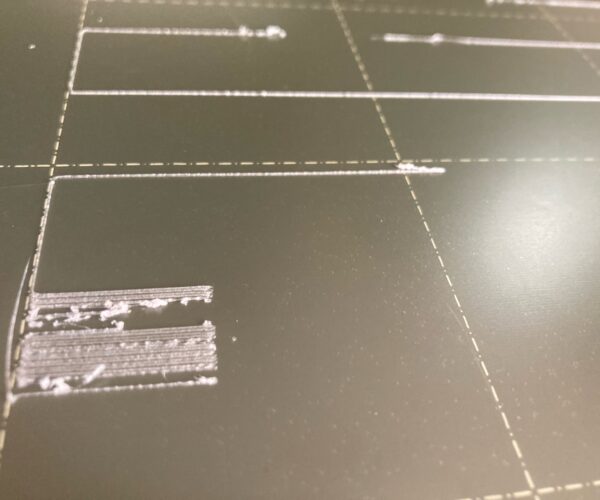

Tried a Cold Pull, still having issues

I tried the cold pull three times but I think it is still jammed or is this a idle screw or z-axis issue?

Best Answer by Diem:

That looks like damp filament.

On page: https://help.prusa3d.com/en/article/pvb_196708

It says:

PVB is very prone to absorbing moisture. Always put the spool back inside the bag with silica gel or let it dry for 4 hours at 60 °C before printing!

Cheerio,

RE: Tried a Cold Pull, still having issues

It could be both. What filament are you using?

I would go back to a Z of zero and try again. If it still jams, try adjusting your tension screw.

--------------------

Chuck H

3D Printer Review Blog

RE: Tried a Cold Pull, still having issues

PVB filament.

Thank you for the reply.

RE:

Honestly, I have a sample and have not used that filament. This image above looks like it might be underextruding or damp.

PVB filament.

Thank you for the reply.

--------------------

Chuck H

3D Printer Review Blog

RE: Tried a Cold Pull, still having issues

Damp as in the humidity around the printer is too humid?

RE:

Is it your first print?

Can you please describe your issue according to this? https://forum.prusa3d.com/forum/english-forum-general-discussion-announcements-and-releases/we-want-to-help-you-you-have-to-tell-us/

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Tried a Cold Pull, still having issues

Hi,

Thanks for the reply.

No, it is not my first print.

Printer: i3 MK3 which I bought fully assembled.

Printer setup: 215/75 standard setup.

Slicer: I use the Prusa slicer but have not attempted a new print since I cannot get a good 1st layer calibration.

Filament: Clear PVB, new Black PLA filament will arrive tomorrow.

Issue started when I walked away during my last print and the filament got too much slack in it and it tied itself in a knot and prevented it from feeding into the extruder. I tried the cold pull three times before re-running the calibration wizard. I got to the 1st layer calibration and the picture in the original post is what I see happen now.

.

That looks like damp filament.

On page: https://help.prusa3d.com/en/article/pvb_196708

It says:

PVB is very prone to absorbing moisture. Always put the spool back inside the bag with silica gel or let it dry for 4 hours at 60 °C before printing!

Cheerio,

RE: Tried a Cold Pull, still having issues

Thank you, you were correct. Got new PLA spool and it is printing just fine again.