Tricky geometry/PETG overhang - Advice needed.

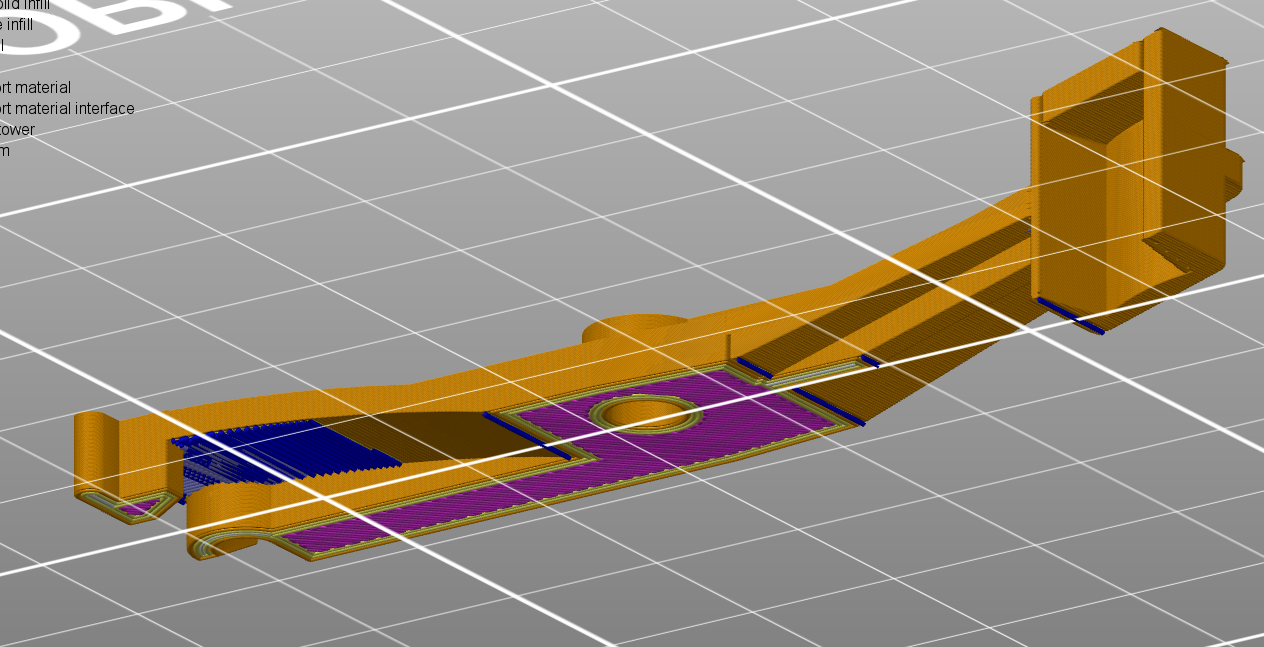

I'm trying to print some tricky geometry in PETG. PLA, unfortunately, probably won't do for this application as I need strength. Problematic features are the 15 degree sloped area on the right, and the arc on the left with all the bridging/overhang blue.

Alas I cannot reorient the part as I will need the layer lines this way for strength and to get smooth x-y arcs/circles in some areas. Also, this placement has the largest flat area to contact the bed. My first attempt was at 0.05mm layer height (for minimum possible overhang on the slopes), with supports turned on (since with them off it becomes a curled, blobby mess). Unfortunately, even with support, it's still a terrible mess on the underside.

What are my options to get this underside better? I am betting there are probably some settings I can tweak (Currently tried both Pretty PETG v3 and Mk3 Quality 0.05) I've gotten good PETG prints before, but those did not have as critical a geometry with these kinds of overhangs.

Or, is this just to be expected for PETG and I should consider "manual" supports and geometry, such as extending some sloped areas to the bed and then sanding/filing them to the correct shape in post-processing?

For places like the arc with all the overhang... would it work to add a thin, easily removable rib to the outer edge (e.g. one extrusion width thick) so it becomes a bridge and not an overhang operation?

Re: Tricky geometry/PETG overhang - Advice needed.

For such a steep overhang I would suggest to go 0.2 or 0.15 layer height and full cooling for bridging. You can also reduce the support separation to 0.1 or even 0.05 but PETG will fuse pretty good together. So just give it a try and see.

At 15 degree you should print in air even with 0.05, so there is no benefit to go high resolution.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Tricky geometry/PETG overhang - Advice needed.

will fuse pretty good together

Yeah, that's why I was considering the route of "custom" supports built into the STL that will be easy to remove but remove some of the challenges with the overhangs. I don't mind going that route and trying it or just tinkering as it's a small part, I just figured I'd check in here first to see if there are any common tricks for this situation, given how good the Mk3 generally is at overhangs and bridges.

Re: Tricky geometry/PETG overhang - Advice needed.

I had one part that had really awful bridging at 0.15mm layer height but beautiful bridging at 0.25 layer height.

I haven't tried pushing overhangs to the limit, but I guess that the ratio of trace width to layer height would have an impact. So if you go to 0.25 layers for good bridging, I would think that relatively thick extrusion widths (0.48mm or more) would help with the overhangs. But you can't print fat extrusions really fast, especially with maximum fan going, so cut back on the speed and maybe use a temperature setting toward the high end of what's suitable for your filament.

Re: Tricky geometry/PETG overhang - Advice needed.

I am attaching some ini files that I use for some nice looking PETG prints with overhangs and pretty easy to remove supports.

Give these a try in your original orientation.

If these don't improve things sufficiently in your current orientation, rotate your object on x-axis to be standing on edge. That should still work with these settings. The supports will help quite a bit with the circular openings and the reorientation will get rid of the troublesome orientation. The higher temperature printing in my filament setting should get you enough PETG strength.

Unzip before using these ini files.

Print settings with supports, gyroid fill, speed changed for cleaner exterior surface

PETG Filament setting with 245C printing but more cooling fan

Re: Tricky geometry/PETG overhang - Advice needed.

Thanks for the suggestions. I have a few other prints to finish first but I'll try this one again soon and let you know how it goes!

Re: Tricky geometry/PETG overhang - Advice needed.

Quick update - it did indeed come out much better with the stock 0.15 QUALITY profile. Acceptable enough to use, I think. But that doesn't mean I'm done, I am still going to give the shared profiles a go shortly in the quest for "better" just because. I've seen fantastic PETG bridging in other parts so I know it is definitely capable of better 🙂

Re: Tricky geometry/PETG overhang - Advice needed.

Hi Vintage PC,

could you add a sacrificial vertical wall on the outside of the unsupported areas, to cause bridging instead of sagging in those areas, and remove the sacrificial wall later

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Tricky geometry/PETG overhang - Advice needed.

Hi Vintage PC,

could you add a sacrificial vertical wall on the outside of the unsupported areas, to cause bridging instead of sagging in those areas, and remove the sacrificial wall later

regards Joan

Yes, that is definitely something I plan to try.

Re: Tricky geometry/PETG overhang - Advice needed.

🙂 let us know if it helps!

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

Re: Tricky geometry/PETG overhang - Advice needed.

Will definitely do, I'm currently printing some R4 parts so should be able to get back to it this weekend after I tear down and rebuild my extruder 🙂

Re: Tricky geometry/PETG overhang - Advice needed.

I had a few more tries with about the same results, namely with the linked profile and also with some strategic supports added. Seems one of the bigger problems is the bridging just doesn't stick to one side, so it folds back on itself in a little loop that makes a bump in the finished surface. Does that mean I just need to go slower?

Re: Tricky geometry/PETG overhang - Advice needed.

Use the slicer's preview feature and select the layer where bridging takes place. Make sure that the preview shows a reasonable overlap of the brige onto the supporting structure. Sometimes if the supporting wall is too thin, the bridge doesn't get calculated correctly because the slicer has an apparent conflict between building the wall and anchoring the bridge. In that case, the easiest solution is to thicken the wall. There are also other parameters you can tune in the slicer.

Re: Tricky geometry/PETG overhang - Advice needed.

I still advise you to rotate the object onto its side to eliminate printing with that much overhang if supports are not getting you the results.

I know you stated that you wanted to avoid changing orientation because of a theoretic strength fear. I think that really isn't going to be an issue if you print it on edge and use high enough a print temperature to achieve good layer fusion. The inter-layer weakness would still only affect loads across the short dimension of the object, not the long dimensions.

An actual successful print done in a different orientation is infinitely stronger than an unachieved, mental print. Rotate the object around the y-axis and print it on edge.

Re: Tricky geometry/PETG overhang - Advice needed.

I still advise you to rotate the object onto its side to eliminate printing with that much overhang if supports are not getting you the results.

I know you stated that you wanted to avoid changing orientation because of a theoretic strength fear. I think that really isn't going to be an issue if you print it on edge and use high enough a print temperature to achieve good layer fusion. The inter-layer weakness would still only affect loads across the short dimension of the object, not the long dimensions.

An actual successful print done in a different orientation is infinitely stronger than an unachieved, mental print. Rotate the object around the y-axis and print it on edge.

Not just that, the other issue is that as designed, any rotation candidates' sides have either similar steep overhangs or protrusions that make it likely to have the same problem. This is just a tricky geometry overall.

I'm not adverse to modifying the geometry but am somewhat constrained because I am replicating a broken part and not designing a new one. But since it doesn't seem to be working as-is (and I had already planned to make an "over-engineered" instead of commercial "minimum plastic we can get away with" variant, I will see if I can rework the ribs somewhat so that it is more FFF friendly.

Re: Tricky geometry/PETG overhang - Advice needed.

One interesting alternative is to tile the object 45 degrees. We do this sometimes printing fan ducts to avoid overhangs.

Re: Tricky geometry/PETG overhang - Advice needed.

One interesting alternative is to tile the object 45 degrees. We do this sometimes printing fan ducts to avoid overhangs.

I totally forgot about the "try printing at a ridiculous angle" trick. That might just work at the right angle and some variable layer height in key places...

Re: Tricky geometry/PETG overhang - Advice needed.

I'm giving away one of my trade secrets here but if it helps i'm happy to share. For very good overhang performance print at 0.2mm layer height. Higher fan speed for bridges and the secret is to put up your extrusion widths for perimeters substantially higher than standard. 0.7mm and above. If you look in the preview you will see what i mean. Will be more interface with the previous outer perimeter where the overhang is.

It can also help reducing the bridge ratio but i have not gone below 0.8 yet.

You can design or download an overhang test model that prints quickly so you can be very sad like me and spend hours trying to improve overhangs.

And yes you are right the standard 0.15 profile actually does a very good job with overhangs.

Re: Tricky geometry/PETG overhang - Advice needed.

Thanks for the additional suggestions.

I eyed a few different angles and I think I can get it to print with minimal support/bridging if I print it in the tall dimension - one I hadn't considered before because tall thin things tend to wobble if not well anchored. But a good brim should hopefully take care of that as PETG likes to stick better than PLA, especially while the bed is hot.

I'll have some more time to tinker in a few days; will report back then.