Transparent PETG

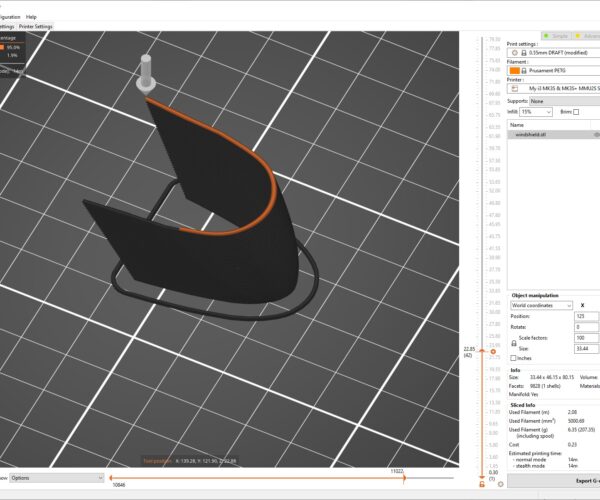

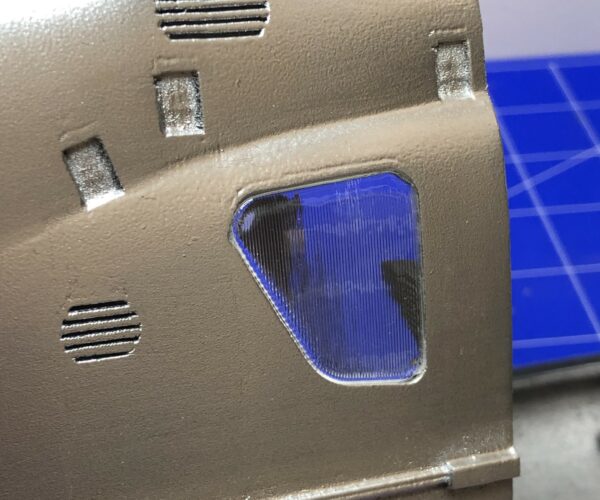

This part is a "transparent" windshield for a model I've bought.

I've printed it ok-ish with the standard nozzle and .2 layer height, but it wasn't very transparent (lots of layer lines).

According to Google bigger nozzles result in more transparency, so I tried with a .8 nozzle I've got laying around.

The lower part prints ok and is more transparent than with the standard nozzle, but...

Halfway through the print the slicer divides the print in two halves (as seen below), first on the side and later in the middle

And because the halves don't touch, this results in holes in the print.

The model itself is only .5 mm thick, but I've enabled thin lines.

I also tried with xy compensation of .2 mm

Fiddling with the seam position also had no influence

Anything I can try next to have only seams at one or both ends of the windshield ?

Is it a slicer problem (the model "looks" good imported in Fusion 360)

Thanks,

Yveske

Having problems with bed adhesion every morning...

RE: Transparent PETG

Read the article "how to print glass.

However, you should think about printing that in vase mode. To get transparent, you need to turn off cooling, change a few settings (read the article) and you will ALWAYS have to do post processing (means lots of sanding).

I printed a transparent window in 3 layers - then used sanding block, progressive sanding from 150 to 1200 grit with water and wet sand paper from 600 on. It came out beautiful totally transparent.

But you cannot expect it to come off the printer like glass without making specific setting changes and going into the project with the expectation to post process extensively. My clear window took me 3 days to get from original print to totally transparent.

RE: Transparent PETG

@dan-rogers

Thanks for your answer, but do you also have a link to the article ?

Searching on "how to print glass" turns up articles about printing on glass, printing actual glass, ...

Having problems with bed adhesion every morning...

RE: Transparent PETG

If the model is only 0.5mm thick, avoid using a wider nozzle. It's true that wider and higher extrusions tend to be more transparent, but walls printed with thin wall detection tend to be faulty and weak. For 0.5mm thick, I'd go with a 0.4mm nozzle with 0.5mm extrusion widths. Experiment with higher layer heights up to 0.32mm. You'll never get truly transparent prints without post-processing, but this might be good enough for your purposes.

Save your current 3MF project file, zip it up, and attach it to a reply here so we can see your part & settings and give better recommendations.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Transparent PETG

@yveske

How To Print Glass by Rygar1432 | Download free STL model | PrusaPrinters

RE: Transparent PETG

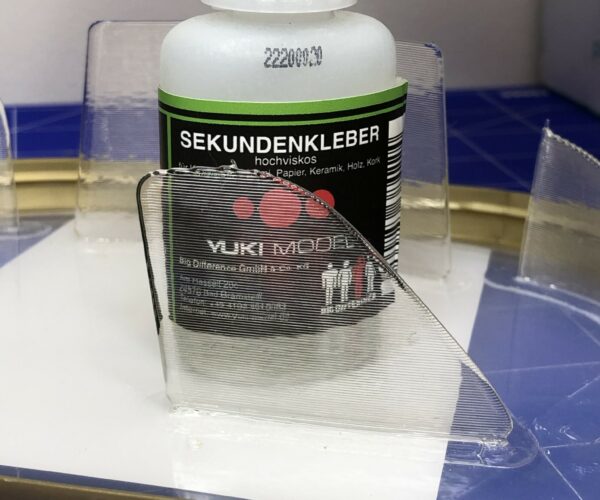

Thanks Dan. Those prints in that article look almost too good to be true. I'll give it a shot with the parameters indicated. I downloaded both the .gcode and .stl. Let's see what happens.

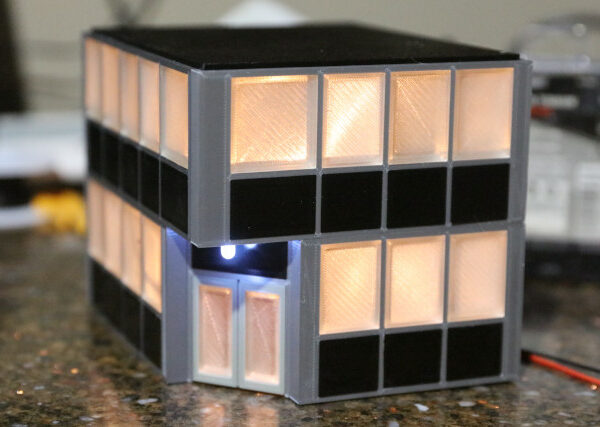

The best I've been able to get with so-called transparent filament, either PETg or ABS is something like this.

RE: Transparent PETG

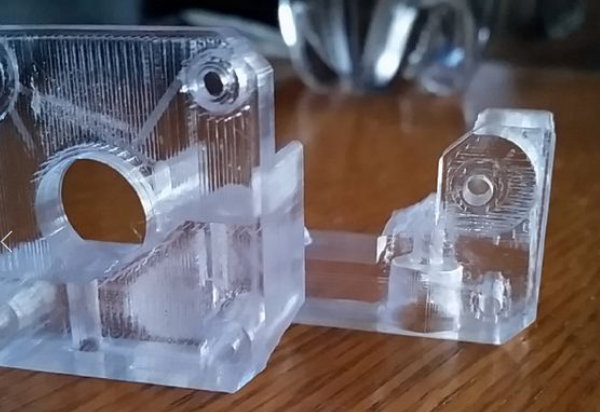

Ok, I downloaded the .gcode file for a test 'cube', which turns out to be more like a 1mm slab. To be honest, I found the results disappointing!

Here's what I get with the .gcode in the .zip printed with Overture so-called transparent PETg. I would assume if I used the .gcode file I should get something very close to what the author has.

This measures 1mm thick with an (old-fashioned dial) caliper. I was expecting something more clear and thicker.

Yes, you can read the text through it, but I daresay that if I took one of the windows from the above building and printed it 1mm thick, it would show the text as well. From a distance, it looks far more like those windows in the building shown above than it does the sample photo in the .zip:

The author did not mention any post-processing.

Am I missing something here?

RE: Transparent PETG

The bird house window that I printed used the PETG recommended in the article, and I was able to use all of the settings except the one that needs the -45 degree setting to get all of the strands to be in the same direction. The slicer wouldn't let me enter the negative number. I have since learned that 315 degrees = -45 degrees for the purpose of that article.

to get around not being able to get all of the traces in the same direction I used concentric fill - which had the effect of getting each layer to use the same fill pattern - goal achieved.

It came out absolutely glass clear for me. but as I said, it took some post processing.

RE: Transparent PETG

[...] to get around not being able to get all of the traces in the same direction I used concentric fill - which had the effect of getting each layer to use the same fill pattern - goal achieved.

Try the Aligned Rectilinear fill pattern at 100% infill. That will align all the infill in the same direction, and with 0 top and bottom layers, all extrusions should be aligned.

It came out absolutely glass clear for me. but as I said, it took some post processing.

Which brand of PETG did you use? I haven't played around with trying for clear prints for a while, but am interested (also for bird feeder panels as well). I usually use a larger nozzle with maximum width extrusions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Transparent PETG

It came out absolutely glass clear for me. but as I said, it took some post processing.

Care to elaborate?

RE: Transparent PETG

@jsw

150 grit

220 grit

400 grit (wet)

600 grit (wet)

800 grit (wet)

1200 grit (wet)

Steel wool.

RE: Transparent PETG

@bobstro

Aligned rectilinear - maybe it IS time to look at the firmware update ... I have been avoiding it due to changes in LA.

RE: Transparent PETG

@dan-rogers Thanks for the link !

Thanks @dan-rogers, @bobstro and @jsw for this treasure trove of info...

Having problems with bed adhesion every morning...

RE: Transparent PETG

Aligned rectilinear is in Prusa Slicer 2.3 and does not require a different firmware on your printer.

RE: Transparent PETG

Also see:

https://blog.prusaprinters.org/3d-printed-lens-and-other-transparent-objects_31231/

Which includes an example of transparent windows in a scale model.

Cheerio,

RE: Transparent PETG

I have tried PETG and clear Polymax, and I could never get a good result even with lots of sanding. I could get a smooth surface, but it would be foggy and nothing I tried got rid of that. My best windows so far have been from using PVB filament and smoothing with IPA. I have also used a 0.6mm nozzle and set it to get just two layers thick, as it is not possible to use vase mode or to get only one layer on an open surface like a window. I still get some visible layer lines but the result is reasonably transparent.

RE: Transparent PETG

I would recommend using an extrusion multiplier of 1.05 with aligned rectilinear, as that seems to fill in all of the gaps for me.