Top part of Print easy to snap off (PLA)

Hi There,

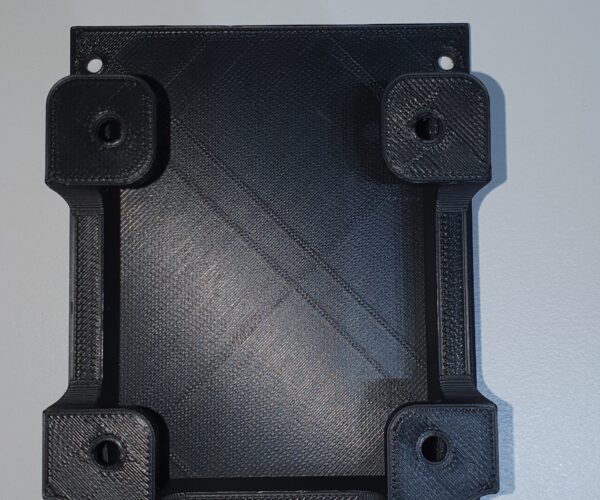

I've made a small battery holder in Fusion360 that consists of a simple plate (3mm thick) with some mounting holes and a couple of

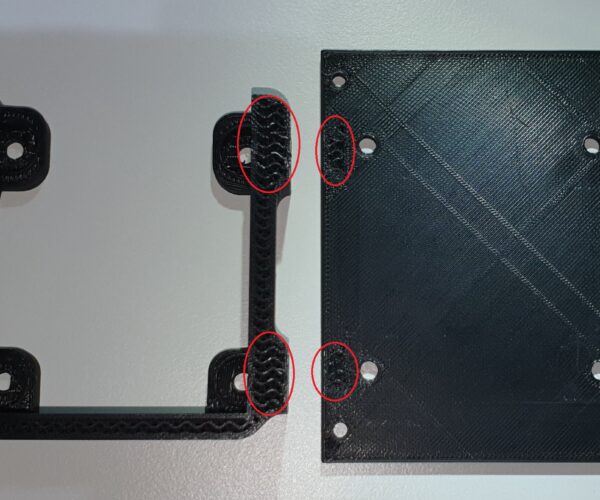

"walls" to hold the battery, the problem is that the top part of the print (the walls) are easy to snap off and (as a whole) and seems that they are not really fused to the bottom plate part, only some parts (marked in red second photo) are attached because of the infill, the rest seems to be printed "ontop" and the adhesion seems to be almost non existent.

The separate parts are quite strong and quite hard to snap/break also the overhanging parts won't break off.

I must be missing something?

I'm using PLA on a Prusa MK3S bearmod with a mosquito hotend and bondtech extruder.

Seems to happen on models that have a flat "plate" and elements "on top" of that, the model itself seems to be fine (solid) and the STL didn't have any errors.

Any ideas on why this is happening? most things I could find are about first layer adhesion but that's all fine.

Thanks! 🙂

Best Answer by Diem:

Infill is almost irrelevant, 100% fill is almost always a mistake; perimeters are where the stresses matter for this sort of thing. I presume the breakage occurs when the battery is inserted and the stress goes from the inside out, so:

Some 45 degree chamfers like this:

...will break up the stress point and extra perimeters will disperse the effect over a greater area.

Cheerio,

RE:

Try adding more perimeters, also chamfer the internal stress point.

Cheerio,

RE: Top part of Print easy to snap off (PLA)

Or you can upload the 3mf project file, zipped up. This way we can offer more educated suggestions, specific to your model.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Top part of Print easy to snap off (PLA)

Yes sure here is the zipped f3d file 🙂

RE: Top part of Print easy to snap off (PLA)

Just an addition,

The "holder" part (the walls that hold the flat battery) seem to be printed on top of the 3mm plate and are only fused on the thicker parts (see photo), when the top part pops off, the bottom plate doesn't even show signs of scarring (its smooth) for the long parts of the walls, even supports leave more marks.

When I print other models they are a lot stronger, maybe it's a slicer setting or maybe an error in my model (however it should be ok since it's a solid)?

here is the zipped f3d file

Not a lot of use, sorry.

It's the.3mf file from Edit > Save Project that lets us see how your design output interacts with your slicer settings.

Cheerio,

RE: Top part of Print easy to snap off (PLA)

Whoops, sorry about that.

This should be the one then. 🙂

Not much to go-on in there, the obvious factor is that the upper part is only connected by the perimeters so I repeat: Try adding more perimeters, also chamfer the internal stress point.

Cheerio,

RE: Top part of Print easy to snap off (PLA)

Thanks for that, i'll try to add more perimeters and increase the infill (80% or something?), probably a stupid question but what does:

"chamfer the internal stress point" mean? is that the same as adding chamfer to the edges (where the walls meet the baseplate part)

Thanks! 🙂

RE: Top part of Print easy to snap off (PLA)

What diem said. With only 2 perimeters and 15% infill I'm not surprised to see the walls snap off under pressure. You should be more lucky with more perimeters and chamfers around the edges of the wall.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Top part of Print easy to snap off (PLA)

Great thanks I'll try that, any advice as to how much infill? I'm not really pressed for time or low on filament so could go up to 100%?

And thanks allot!

Infill is almost irrelevant, 100% fill is almost always a mistake; perimeters are where the stresses matter for this sort of thing. I presume the breakage occurs when the battery is inserted and the stress goes from the inside out, so:

Some 45 degree chamfers like this:

...will break up the stress point and extra perimeters will disperse the effect over a greater area.

Cheerio,

RE: Top part of Print easy to snap off (PLA)

Great thanks! ill try this 🙂

RE: Top part of Print easy to snap off (PLA)

Great that worked,

The print is much stronger now (does not snap off)

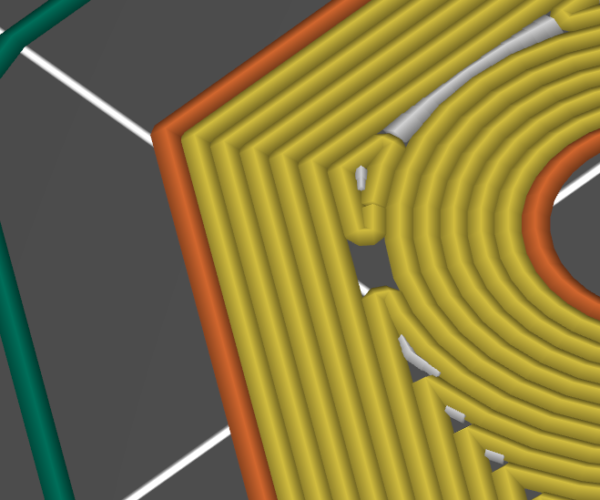

The only side effect I was wondering is that there are small holes (just two) and when I check the slicer (see picture)

I see that these two areas are indeed gaps, can these gaps be filled?

I was playing with the:

- (Advanced - Slicing) Slice gap closing radius (currently set to 0.049)

- (Infill - Advanced) Solid infill threshold area (currently set to 0 mm2)

- (Layers and perimeters - Advanced) Fill gaps (currently set to enabled)

The current settings leave the gap, so I might be missing something (for this model it's no problem, just wondering if it could be "fixed" in case I have another model that needs to be "closed")

This sort of gap is a function of the thickness of the wall and the extrusion width, especially with curves there are places where an integer number of extrusion widths does not fit - if there is fill within the structure the slicer can compensate but where there is 100% fill or solid perimeters it is almost impossible to eliminate all of them. Tweaking settings moves them more often than it eliminates them, sometimes it is enough to shift a weakness away from a critical point.

Cheerio,

RE: Top part of Print easy to snap off (PLA)

Ah great that makes sense! 😀

I really appreciate your explanation thanks!