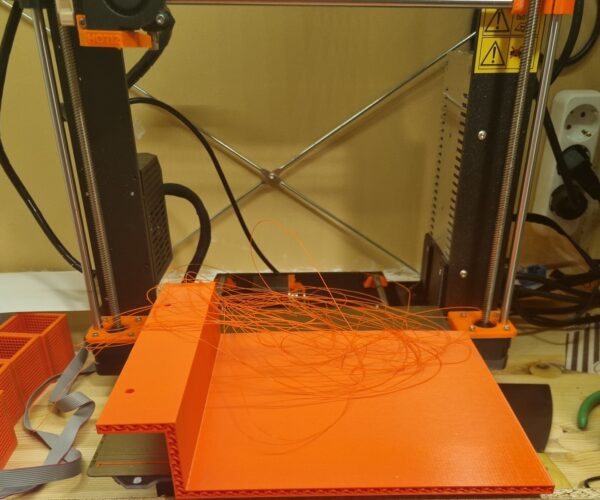

Tall print knocked over

I had a 15 hour print job printing a pretty tall shelf thingy. When I left for work everything was working great and the job was over 50% complete. When I came home the print had been knocked over served with bit of spaghetti as can be seen in the picture above. Anyone have any theories as to what happened? Was the print simply too tall? I've attached the project file in case anyone is interested. Looks to me like there were only few layers left when it got knocked over.

RE: Tall print knocked over

here is the gcode if anyone is interested in that. Couldn't figure out how to put that in one post.

RE: Tall print knocked over

g code never posted you need to put it in a zip file

Please help me out by downloading a model it's free and easy but really helps me out https://www.printables.com/@Hello_474427/models

RE: Tall print knocked over

When I try to attach a zip file I get blocked for unsafe operation. I've made the zip file available at https://supergeek.us/mousepad.zip lets see if that works better.

RE: Tall print knocked over

I suspect you are getting some vibrations at greater heights. For anything really tall, in particular if there's also a small contact surface with the steel sheet like here, I'd model throwaway supports in to stabilize in the vertical dimension. You may avoid the getting-loose part by adding a large brim, but vibrations may still produce some imperfections.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

It's a combination of the Y acceleration and slight drag from the molten filament that made your print topple over. Both of these forces will increase the torque on your model as it gets higher. It's also the repetition of these forces that will over time make your object lose adhesion.

You could add a brim for better adhesion. That will probably do the trick already. Other options are reducing Y acceleration or rotate your object by 90° so that the forces of the moving bed are along the plane instead of perpendicular to it (but this model is too large for that).

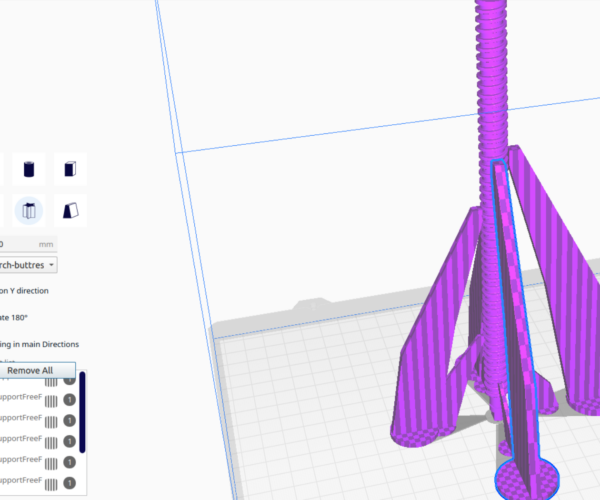

Cura has a 'Cylindric Custom Support' extension which allows you to add side support (arch-buttress) for tall prints. I set the 'Support X/Y distance' setting to 0.1 mm. That will make the support barely touch the side of your model. Enough to keep it in place, but still loose enough to easily break away without leaving a big scar.

I am not aware of such a feature in PrusaSlicer. I tried it with paint-on organic supports, but those are ignored on vertical walls :(.