not holding out hope on PVA

I've not had good success with PVA.

I was just watching the interface layers go down for the first print and I'm thinking I might have to have less bridging. PVA doesn't bridge well in my experience. I've never tried to print so much supported material lol.

But maybe I'll try it again with less distance between the supports.

Renovating the mmu2

I have just found out about the different varieties of PTFE tubing used with the MMU2 (1.85mm ID inside the extruder and 2 to 3mm from the buffer and a special tube between MMU and extruder), also that there is a special heat brake for the hot end. I have all that stuff on order and will see if it helps any. Also I am adding Festo Pneumatic connectors to the input of the MMU. Seems like Prusa should do a better job documenting things like this. They must have noticed by now how much trouble people are have getting the MMU to work.

PTFE tube length

Do you know what length the PTFE tube in the hot end should be? I have been trimming it to be as long as possible, but it occurs to me that because the tube swells and softens when heated that this might cause it do deform and create a restriction because it has no room to expand. The other side of the argument is that if the tube is shorter, that it might result in creating a cavity above the heat break that accumulates melted plastic which hardens into a plug when cooled. So what do you think?

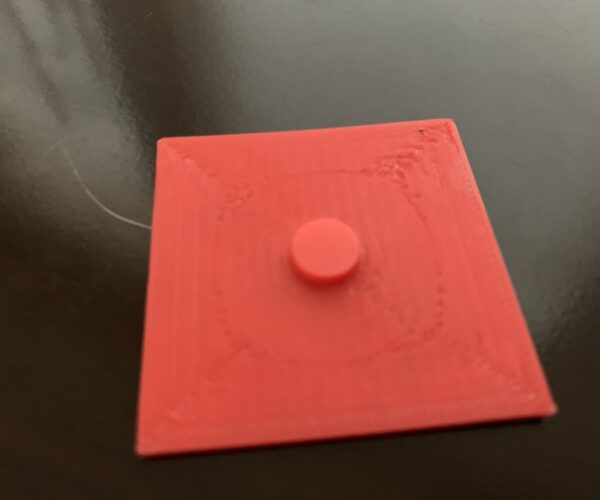

Chamfer?

Thanks. From the picture it looks like there's an outside chamfer on one end and an inside chamfer on the other, is this correct and which end is up?

correct

rounded(exterior chamfer) end goes down.

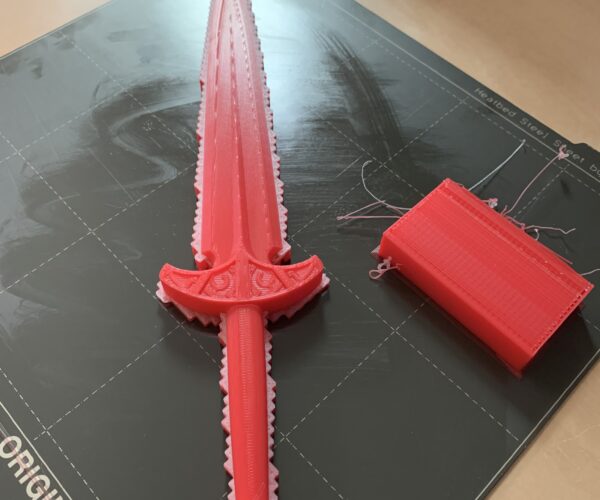

Nice

What were your parameters and what is the length of the piece?

Settings

It’s slightly shorter than the diagonal of the plate. I sliced it with 2.4 prusaslicer. I can attach .3mf tomorrow if you want

File

Yes, I would like to have the 3mf, it will come in handy when I get my MMU running again.

RE: as requested

Again this is done with PrusaSlicer 2.4.0 as built from master so don't try to open it on 2.3.3.

3MF received

Thanks for the file, please send the BVOH file also once you have success. BTW: Do you know of any documents that explain what the buttons on the MMU do in reality. I have never been able to use them successfully in the manner Prusa documents.

same file

The file you have should work, just change filament 5 to be verbatim bvoh.

I also change the layer height for this print to .15 from .2. otherwise the same settings as the PVA one.

The best practical explanation of all the MMU buttons is here

MMU theory of operation

Excellent, Excellent, Excellent

I'm in love again! All of my questions were answered and some of my suspicions confirmed, I wish I had seen this two years ago it would have saved hours of confusion and many failed prints.

if you watch it enough

Stuff starts to make sense after you've watched the MMU in operation as much as I have lol. but I'm truly excited to see this work for you. It really is cool to see it work.