Supported layers are stringy

When I print large surfaces that are parallel to the build plate but are raised above it, the bottom layer is stringy rather than solid though it is supported. The layer looks as though it was bridged rather than supported. I have seen this with both PLA and PETG but suspect it doesn't have to do with the type of plastic. No such problem exists if the layer is resting on the build plate only when it is supported above it. Does anyone know how to fix this?

Thanks,

Steve

Known issue with PS generated supports

This is a well known issue related to the algorithm that prusa slicer uses to generate these types of supports. You may see better results with such a print by slicing with a different slicer. My understanding is that the folks that work on Prusa Slicer are working on improving the quality of prints above supports.

expected

You can get somewhat smooth supports if you have an MMU and use soluble support material. But if you're laying down plastic on the same kind of plastic, you can really squish it down if you're hoping to break away the supports later.

typo

That should have been CAN'T squish

It IS bridging!

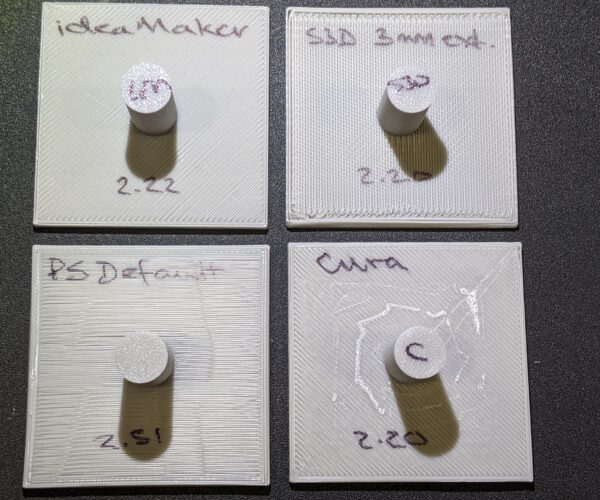

The supported layers ARE actually bridged. As @dan-rogers notes, it's a known issue. Here's a quick comparison between supported layers on a 50x50x2mm test created with 4 common slicers. From left-right, top-bottom: ideaMaker, Simplify 3D, PrusaSlicer, and Cura. IME, ideaMaker currently has the nicest supports for flat supported layers, Cura's tree supports work well for things like miniatures with irregular shapes.

Notice that the PrusaSlicer result is ~.3mm thicker as well as stringy. The good news is that, given the pace of PrusaSlicer development, this will probably be a non-issue for PrusaSlicer at some point.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

interesting

I should set up that test in the lastest master build(from this morning) and see if that has improved. I simply don't try it these days. If I have to print something that needs that kind of support I do it on the MMU printer with BVOH.

If you attach that .3mf I'll try to print it sliced with the latest PS.

Some improvement

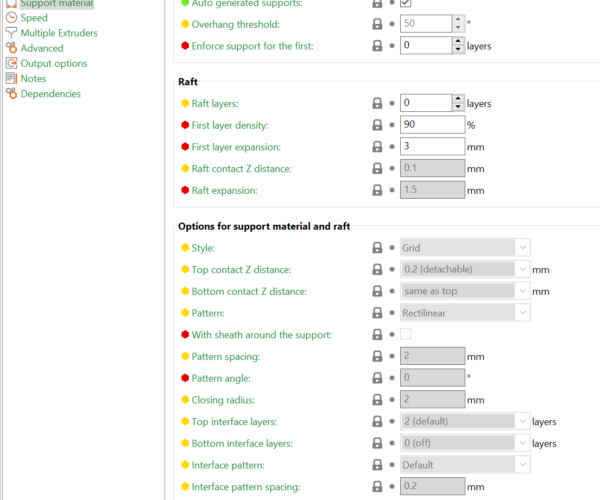

I got some improvement by using interface layers, which I try to avoid because I find them hard to remove, but the finish is still ugly. Attached is the project.

BTW: I have an MMU which has never worked very well and my attempts to use BVOH with it were not successful, I may try again based on your suggestion. One of the most frustrating things about the MMU is that it fails to recalibrate under certain circumstances and consequently remains out of sync. Another is that I have never been able to get the buttons to do what the docs claim they do, I suspect they are being remapped depending on the situation, very confusing. I have changed the controller board twice with no improvement.

STLs attached

Here's are the STLs for a couple of variations. I don't bother keeping 3MF for these as each test is unique.

Note that I'm not trying to troubleshoot this with PrusaSlicer. I'm getting excellent results with ideaMaker. I'll happily try anything new they add to PrusaSlicer, but the results are simply ugly for now.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Please post pics of your results

They added a lot of knobs to turn in 2.4 alpha. So it's worth revisiting. I'll try to print with a few and see what happens.

Please post a quick pic if you can. So long as PrusaSlicer still insists on laying a layer of bridging underneath, I'm not going to bother. I think the current approach -- inherited from Slic3r way back when -- made sense when bridging was much more difficult, but ideaMaker shows what results the Mk3 can get by simply tweaking the Z gap. Supports are the one big weakness in PrusaSlicer remaining, but they are making amazing progress.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

printing first test now

I am printing first one now, with defaults on. Just to see.

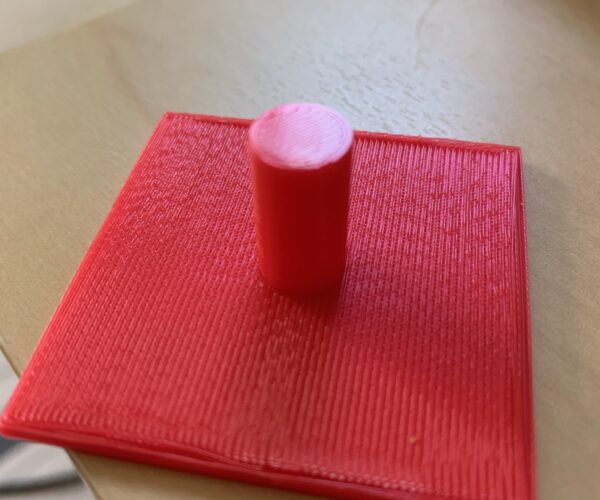

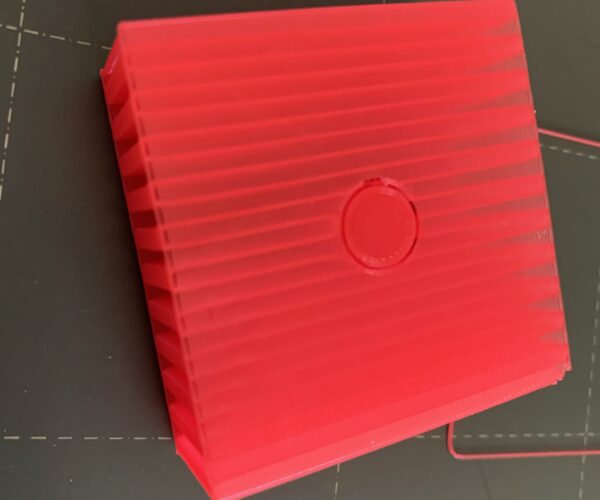

Definitely an improvement

Here's the first attempt with defaults in 2.4.0 alpha(built from master this morning)

That's definitely an improvement. Looks about like S3D with a bit rougher around the edges. Hopefully, they'll refine it a bit before the full release. I'm curious what exactly ideaMaker does to get that cleaner underside. Their supports also release very nicely.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

needless title

I'm doing another print with some tweaks. I also added your second .stl to the mix. I'll report back if I get anything better.

MMU

Oh there are definite cases where the MMU and printer can get out of sync. No doubt about that. They are apparently rewriting the MMU firmware from scratch to improve things. Though it sounds like the tzb extruder guys have already done this. I've been tempted to try out their stuff. They have some modified extruder parts and a modified mmu and printer firmware that actually do what the prusa guys says they are doing in the rewrite. They also claim that with these mods you can print tpu with the MMU. Now that I have my stuff dialed in though I'm reluctant to change to non-prusa modifications. I've not done any soluble support prints since getting this all dialed in, but with just multi colored prints I have no worries about kicking off a 2d 1700 tool change print and having it work. The problem I had with solubles that required a bit of a kludge was the wipe tower. In order to keep the soluble filament from just flaking off when it's written to wipe tower I had to artificially have the slicer put an X right in the middle of the the wipe tower that touched all four corners. This was not something I figured out, butI saw someone had posted it as a kludge on a github issue against the slicer. It works like a charm.

Thanks for the tips

I was beginning to think the MMU had been abandoned by Prusa because the problems weren't being fixed, it's good to hear they are still working on it. I may switch to TZB just because I am tired of waiting for corrective measures from Prusa. I found a mechanical problem with the MMU that I have not heard others complaining about. The bearings used to pinch filament against the bondtech gears are not designed to take axial loads and so the pinching surface can wobble relative to the axel resulting in it not being parallel to the bondtech gears. I think this generates friction that causes grinding on the filament. I have tried using shims to trap the bearings and prevent the wobbling, it seems to help in my case. I am planing to 3D print some shims to replace the original paper ones. The shims are cut so they have the same outside diameter as the bearing and trap it against the pockets in the selector drum.

mmu

Here's my current setup. I'm using stock parts(printed in different color) except for the horizontal mount and the M10 PTFE connector pass-through on the back which I feel are the only real required mods to get things to work.

I can't stress enough that the idler bolt being flush with the hex nut on the extruder and the heads idler bolts on the MMU being flush with the surface makes the difference. Also be SURE to calibrate finda and IR sensors. If those aren't calibrated correctly you'll run into all kinds of issues.

You and I must be psychically linked

Referring to the pictures, my setup is much the same as yours including the dangling filaments and horizontal mount for the MMU. I have found that the filaments may tangle but they don't knot, and that if you don't mind the mess, buffers and retractors aren't necessary. One modification I am considering is to mount the MMU so that the output is directly in line with the extruder to eliminate the arc in the connecting tube. That will mess up the finda sensor and require some sort of mod to it since it depends on gravity.

if it ain't broke don't fix it

I'm inclined not to mess with mine now. It's working pretty reliably lol

soluble supports

sorry I finally got back to this. I realized that since "taming" the mmu I've not gone back and really tried the soluble stuff again. I have 3 kinds of soluble filament. PVA, BVOH and Aquasys 120. I had zero success previously with the aquasys, but I feel I've learned a decent bit since I tried and I'm willing to give it a shot. But I'm going to run some tests first with the two I have had work before, PVA and BVOH. I'm going to try printing the test model above and see what kind of surfaces can be had with 0mm zContact distance with the latest slicer.

I'll post some results here when I've got a print done.