Support material settings for small overhang?

I'm printing a small part with a circular overhang about 10mm wide. The support material doesn't come off as cleanly as I'd like and I'm looking for advice on these support material settings to see if I can improve it. Attached are the settings I am currently using, which does work well for much larger parts.

Best Answer by Amoda:

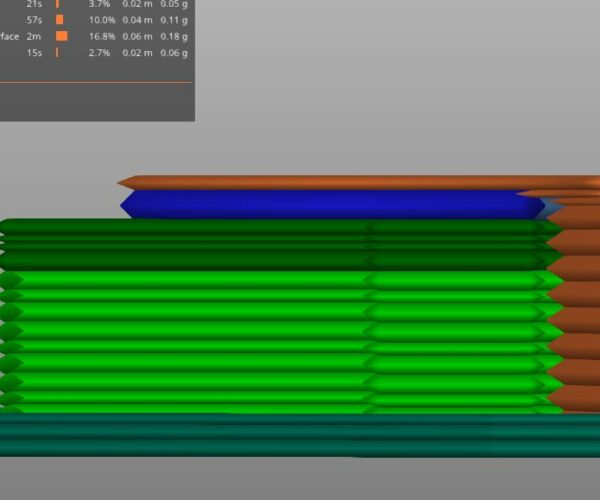

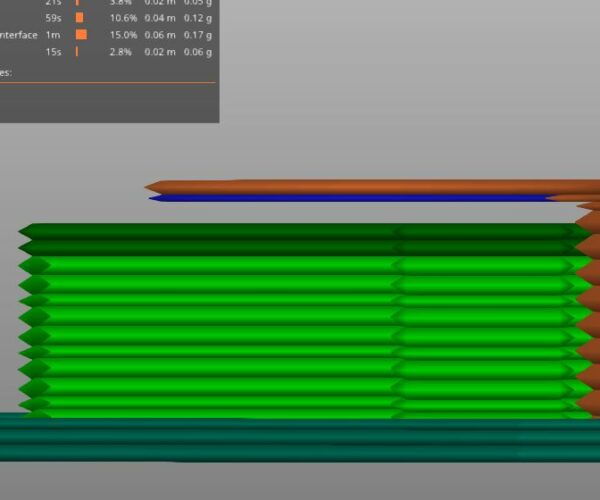

In previewing the model. The slicer is creating a solid layer against your supports. When I uncheck 'thick bridges' this goes away. I think the slicer is interpreting the area as a bridge and creating thickness there. By unchecking that setting you may find it resolves your issue.

Edited to add:

Though you may find you need to reduce your top contact z distance in this scenario if you find it does not give adequate support.

RE: Support material settings for small overhang?

Can you provide additional information such as your layer height, nozzle and a quick picture of the print to show how the slicer preview looks? This provides a bit of context. Also, when you say it does not come off cleanly, where are the supports causing issues? (top, bottom, sides?) Do you have small bits of support hanging on like threads or is the whole top layer of the support fusing to your model. A picture would be helpful for context. Is the area supported enough or is it still sagging when you remove the supports?

RE:

Can you provide additional information such as your layer height, nozzle and a quick picture of the print to show how the slicer preview looks? This provides a bit of context. Also, when you say it does not come off cleanly, where are the supports causing issues? (top, bottom, sides?) Do you have small bits of support hanging on like threads or is the whole top layer of the support fusing to your model. A picture would be helpful for context. Is the area supported enough or is it still sagging when you remove the supports?

I'll try to attach the .3mf file... (EDIT: I guess I can't attach a .3mf file)

Layer height = 0.15

Nozzle is 0.4mm

The whole top layer of the support is fusing to the model. The sides come off clean.

RE: Support material settings for small overhang?

You have to zip the .3mf file

RE: Support material settings for small overhang?

To attach the 3mf file you have to zip the file. I should have mentioned that.

The quickest test is to simply lower you top contact distance. Anecdotally, I have found that the top contact z distance should be around 1-2 layer heights depending on how much contact the model has with the support. However, you have a large contact area. Since the contact area is so large, I would push that to a definitive 2 layer difference. In your case 0.3.

RE: Support material settings for small overhang?

Here you go...

RE:

In previewing the model. The slicer is creating a solid layer against your supports. When I uncheck 'thick bridges' this goes away. I think the slicer is interpreting the area as a bridge and creating thickness there. By unchecking that setting you may find it resolves your issue.

Edited to add:

Though you may find you need to reduce your top contact z distance in this scenario if you find it does not give adequate support.

RE: Support material settings for small overhang?

In previewing the model. The slicer is creating a solid layer against your supports. When I uncheck 'thick bridges' this goes away. I think the slicer is interpreting the area as a bridge and creating thickness there. By unchecking that setting you may find it resolves your issue.

Edited to add:

Though you may find you need to reduce your top contact z distance in this scenario.

I noticed that solid layer also but didn't think to try and change it. Thanks, I'll give this a try.

RE:

Bonus tip, in the slicer preview you can use the num pad on your keyboard to view the slice on face. This can be helpful when troubleshooting these kinds of things. It was something I did not become aware of until recently. 🙂

Good luck!