Support material interface is of poor quality, what can I do?

Hi,

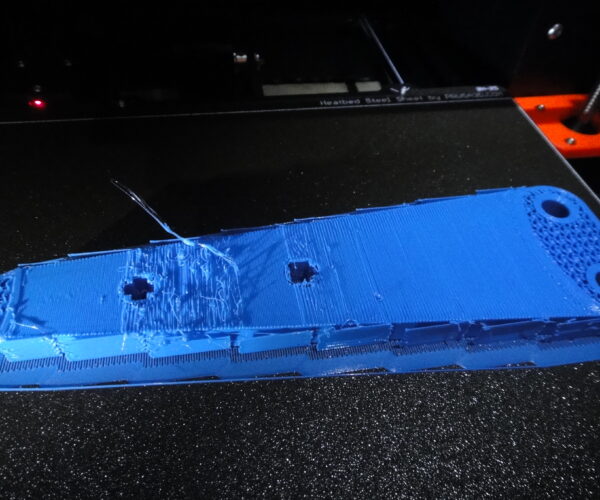

It seems I have a problem with the "support material interface" with PETG . The first layer and the Perimeter layers, external perimeter layers and internal fill layers are perfect, but the second support material interface layer is of poor quality. See below picture. This second support material interface layer is destroying all further support material layers.

This post is a follow up of my previous post: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-how-do-i-print-this-printing-help/blob-half-way-my-print-how-can-i-avoid-this/#post-195835

- I am printing with PETG from HotOrange3D.

- I am using the generalPET settings of prusa-slicer with 0.20mm QUALITY MK3.

- Don't support bridges OFF

- Printer is housed in a box with a temperature between 30 and 34 degrees Celcius.

Can someone help?

Cheers

Bas

RE: Support material interface is of poor quality, what can I do?

I reduced the print speed to 70% and that helped. I will do another test with reduction of the print speed of the support material only, later on.

RE: Support material interface is of poor quality, what can I do?

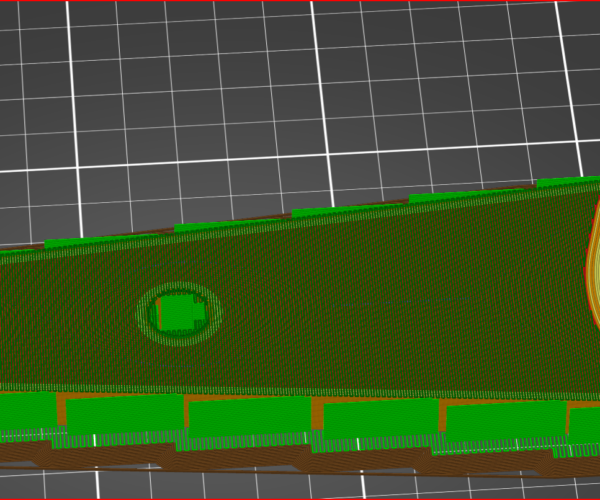

With supports and PETG you really need to use the layer preview slider on the right to see how the layers interface and play with the settings to get the correct support, also make sure in slicer print settings that contact Z distance is set to 0.2 (detachable), and finally the most important change I find gives me the best results, make sure your support contact layer is not in the same direction as your supported layer, hence the reason for using the layer preview slider.

If the layers run the same way, they will stick along the whole length, if at an angle, they will only stick where they touch and these contact layers are not squished together like normal layers, but each extrusion line remains somewhat round so will only join where they touch each other, so use the pattern angle setting to make the layers run at 90 degrees or 45 degrees to each other but definitely not the same direction.

You need to play with these settings on a test print to get the hang of supports with PETG, try increasing the pattern spacing to 3 and the interface layers t0 1, this results in the interface layer sagging slightly between the patter spacing extrusions, so you have less interface material in contact with the print, but again this also depends on your print, sometimes, you have no choice but really support it well, but try to get the interface layer running at 90 Deg to the print when possible.

I used to avoid supports with PETG, now I use support modifiers on intricate prints where part of the print is at a shallow angle or curves over.

You do need to study the layers and adjust settings to get the best results out of your print, and use modifiers for spot supports rather than support everywhere, try to avoid this option if you can.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Support material interface is of poor quality, what can I do?

@chocki

First of all, thanks for your tips. At the photo above, the first and second support material interface is perpendicular to the top layer below. I will try to skip one support material interface layer as you mention. But why is this second support material interface on my photo so bad?