Starts fine, then jams

I'm frustrated beyond believe at this point and I would love some help.

Everything was working until I had a jam in the tube and had to replace it.

Now every print gets about 50-60 layers (it varies sometimes it gets over a 100) in then I hear the click click click of the extruder trying to push the filament down. I can stop the print and run the filament unload setting and get it out (unless I'm not there, then we have filament stuck in the tube again). Then put new filament (or same filament) in with no issues with it extruding.

Things I've tried:

I had a nozzle X and replaced it with a harden steel nozzle.

I've replaced the tube again. (these are Prusa specific parts, not something I've customize)

I realigned the gear to make sure it is all align.

I've tried multiple different filament (PLA / PETG / ASA) and it happens on every print.

I've run cleaning filament (Nozzle X)

Not that it matters, but I even tried changing out build plates.

I'm completely baffled, and it's sitting in pieces (have to dismantle to replace the tube). I haven't had a successful print from in weeks.

Please help

Filament won't melt and forms plug

I believe I'm having the same problem. I have good filament that will print for hours without problem. Then for some reason, the filament just stops flowing while the extruder slowly grinds away. When I am able to eject in time, the tip seems to always form a perfect squared off plug. If I cut it off, I can print for another hour or so, then another plug forms. I cut that off, and print for another hour then another plug. I would love some insight into what is going on.

I *think* I figured it out

I *think* (testing now) I figured out the issue. It's ironing. I noticed last night that another test that it only started to do it when it got to a flat surface that it *should* be ironing.

Running the same print today and will let you know.

An obvious example why it should be mandatory to post a 3mf file with all the settings. That way maybe someone had spotted that ironing was turned on. Without that, nothing to go on.

But glad you have (hopefully) figured it out! I haven't used ironing much. The few times I ended up with clogged nozzles and artifacts. Seems too much hassle to get it right for my use.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

@fuchsr

The thing about the settings file, 1) it's not mandatory and there is no pop up when you create a question that suggests you include it, and 2) I had tried multiple different settings in my testing (however ironing was indeed on in all of them).

I have had great success with ironing on my ender through cura and assumed (I know my fault) that I would see a similar experience with the prusa.

My test print is still running, but so far no issues.

Still having problems

Unfortunately, I don't use ironing and the issue frequently occurs during the infill layer. I would upload the gcode for someone else to try, but the forum won't let me. Just in case, I will reslice and try again after I cleaned out my hot end again.

Did not fix the issue.

Well, it managed to print that test print ok, but the very next print (different model) I ran into issues again (no ironing this time), and happened during infill this time.

I would upload the gcode for someone else to try, but the forum won't let me.

No, and the gcode file would be less useful anyway. Go into Prusaslicer, set up your model and slicer settings. Then go to the File menu and Save your project as a .3mf file. Now, and this is a key step, zip your file. On windows that's right click send to archive, on Mac that's right click compress. Now you can upload the .3mf.zip file to this forum. The 3mf contains the STL and all your settings.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: file

Here was the latest print that failed

RE: Starts fine, then jams

Hi Eric,

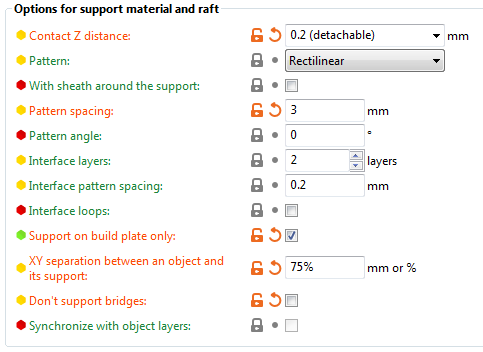

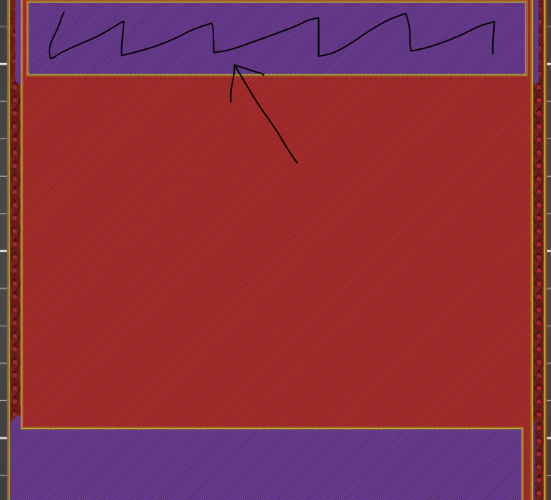

I just took a look at your .3mf project file, a few things I noticed, you have "support on build plate only" selected however the only area it will effect on your model is the circular bridged areas on the bottom. these areas are currently being blocked from supports by the (Ticked box) that says "Don't support bridges". If you intend to use supports you will want to Un-Tick this. As well you will want your support settings to look something more like this suggested example for easier release/ clean up.

If you didn't intend to use them It's generally a good idea to select none. also while on the subject of support there is a large triangle shaped bar spanning the inner wall of the model that is not attached to any other part of the model and it's floating in mid-air, so to speak.

This will most likely result in a failed print shortly after it reaches this height.

Lastly, and this is the one that I think is causing your failures at around 50ish layers, your infill is set to Gyroid 15% I'm going to suggest "Support Cubic" at 15% this has the effect of saving approx 4 hours of print time and approx. 40 grams of filament while offering great strength for the body, another reason I suggest this is that In my experience Gyroid tends to clog the extruder, (YMMV).

Good luck, hope this helps.

Swiss_Cheese

The Filament Whisperer

Unfortunately still not fixed

You were completely correct on that model. It was broken and needed to be completely reworked. However, the suggestions didn't fix the issue.

I am confident I have narrowed down the issue.

As it prints, the Z axis does not move up as much as it should. I have tested this on numerous prints now and have determined that if I baby sit a print and manually add around .02 to the live Z tuning every layer I can get a successful print. HOWEVER, if reach 0 in the live Z tuning then there is nothing more I can do and the nozzle will dig into the print. When I start a new print, I have to then reset my Live Z tuning back to the original number.

This why I first thought it was related to the ironing, but it's not.

So because of this issue, if I print anything I have to baby sit it the entire time. Additionally, if I miss a couple of layers filament gets on the hot end making nasty blobs on the print. The filament gets backed up and clogged in the tube.

Can you help me calibrate the Z stepper? Do you think that is where the problem lies?

Having to adjust Live Z while the printer is moving up the Z axis is certainly not the Prusa standard for 3D printing...

If something smells like a serious hardware issue, I'd get on the chat with Prusa Support, especially if your machine is still under warranty. If they can confirm it's hardware related, they can send you replacement parts right away. Go to https://shop.prusa3d.com/, log into your account, and then click on the Chat button in the lower right corner.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/