Recent extrusion and adhesion issues - unable to print anything successfully

I received my Prusa i3 mk3 in early 2018 and it printed like a champ right from the start. For at least a year and a half I experienced hardly any issues at all, printed all sorts of PLA, PETG and some ABS - generally, everything just worked and was pretty foolproof. During the latter part of that time, I mostly printed PETG due to the strength and tolerance of higher environmental temperatures.

I installed the MK3S upgrade kit sometime last year and aside from the filament sensor (which has been very flaky, despite repeated debugging) it continued to print nicely for a while.

Late last year, all of a sudden everything started going badly. All of a sudden I was unable to get nearly any PLA print to stay adhered to the bed (original smooth sheet), which is a problem I had never encountered before at all. I cleaned it a bunch of times, alternating alcohol and acetone, to no avail. Ultimately I took another recommendation and scuffed it lightly with fine-grit sandpaper to give some texture and that helped some - but at that point I ended up switching back to PETG since that had always adhered so strongly.

Then I began having endless issues getting PETG to actually print. I had been using Atomic Filaments PETG for a while and had printed a couple spools of it with zero issues previously, but recently I seem to be having all sorts of issues - failed prints with birdsnests and/or big globs of plastic, quite frequently. I tried doing cold pulls a couple of times, but they came out clean and didn't really seem to tell me anything.

I bought a textured sheet just to have a brand new, clean start, figuring that PETG should stick to it okay.

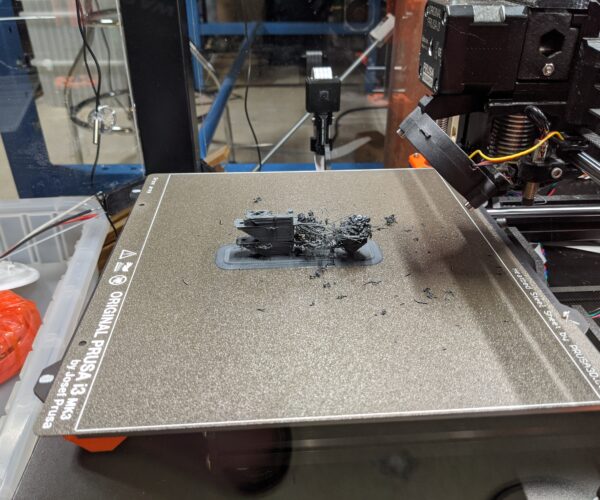

At this point it feels like the issues I'm seeing are almost random on each print. Thinking temperature may have something to do with it, I tried printing the PETG version of this popular temperature tower from the prusaprinters.org repository, and the result was such a complete and total failure (see below) that I don't even know how to begin diagnosing it.

I then printed a different temperature tower which still failed but only near the top (cooler temperatures), leading me to bump up my extruder temp from 240 to 250 (note that I had previously printed a lot of the same PETG at 240 without any prior issues). I printed a benchy at the new setting and it printed to completion without incident, so I thought I was alright. I then proceeded to print a real part with rather simple geometry, and saw several strange extrusion issues in the first few layers, and then it turned into a total hot mess as soon as it started bridging over a support region in the middle.

I've tried printing that same part multiple times throughout the course of debugging. Once I got a big (~5mm) layer shift despite crash detection being enabled; sometimes I get significant warping, sometimes with corners lifting badly enough to cause a crash. I've gone through the self-test, tightened belts, re-done XYZ cal and repeated first layer cal multiple times. It feels like nearly every print something goes wrong, but it's usually something different each time.

I'm trying to get a complete new hotend assembly to just do a wholesale replacement in the hopes that maybe it will make a difference - but other than just throwing new parts at the machine I'm really at a loss as to what to do.

I welcome any recommendations for ways to *methodically* work through this - specific test prints to identify specific faults, etc; right now the fact that it seems to be so inconsistent is making it very hard for me to know what to focus on. I really want to get this machine back to being nearly bulletproof, like it always was before!

Best Answer by bobstro:

I'd start with a PID tune just to ensure the temperatures are calibrated for your current hardware. This is usually only necessary after hardware changes but is a good idea if your regular temp changes.

RE: Recent extrusion and adhesion issues - unable to print anything successfully

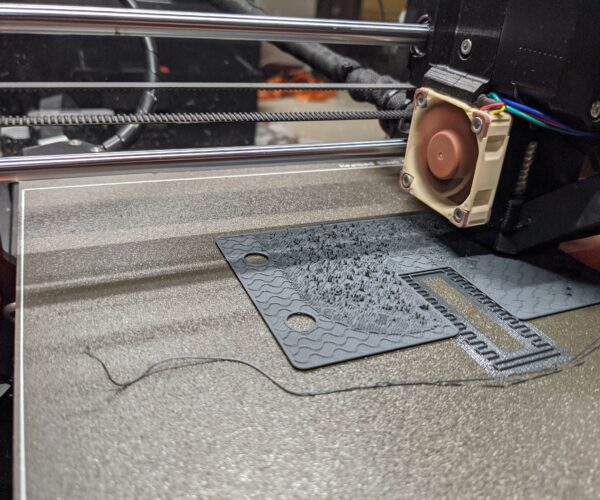

Here's the subsequent print I mentioned showing the unusual extrusion issues after several clean layers, which later ended in a total failure once it started bridging over the supports:

I've tried printing PETG using both the default Prusa PETG setting in Prusaslicer, as well as a slightly modified profile that I had been using for many months (max volumetric speed lowered to 5mm^3/s, temps were at 240/80 but I've now raised extruder to 250 based on temp tower results, and bed to 90 to help with the warping/adhesion issues I'm getting)

RE: Recent extrusion and adhesion issues - unable to print anything successfully

Your problem can be quite easy to fix. Wash the bed thoroughly with detergent and warm water, wipe with paper and then do not touch the bed with your fingers. Alcohol does not help here and certainly not Acetone which can destroy the bed.

If the problems remain, check that the first layer is smooth and fine without any slips. In difficult cases, adding a few mm of brim can help.

Bear MK3 with Bondtech extruder

RE: Recent extrusion and adhesion issues - unable to print anything successfully

During the course of trying to debug my PLA adhesion issues, washing with soap and water was one of the things I tried, and that did help some, but not completely. However, I've set the PLA adhesion issues aside for the moment because the extrusion issues I'm experiencing in PETG are far more of a problem, so that's more what I'm looking for help with here.

Note that in both of the above photos, the first few layers were fine (well, other than the skirt on picture #2) and both of those prints stayed adhered - the major issues began after 1-2mm of print height, so they weren't first-layer adhesion issues.

RE: Recent extrusion and adhesion issues - unable to print anything successfully

I'd start with a PID tune just to ensure the temperatures are calibrated for your current hardware. This is usually only necessary after hardware changes but is a good idea if your regular temp changes.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Recent extrusion and adhesion issues - unable to print anything successfully

Is it clear to you that you need to fully recalibrate Z if you are using another sheet?

What I´d do:

Reset the printer to factory settings, then flash the latest update.

Update the slicer software to the latest update.

Run an entirely new setup of the printer, including an alignment of the X axis with a sheet of paper, as in Josef´s beginner video, then I`d go for Jeff Jordan´s Live Z calibration method instead of several times repeating the Prusa Live Z adjustment.

Cleaning my smooth PEI sheet with hot water and lots of dish detergent, then rubbing it thoroughly and relentlessly with kitchen paper towel. It´s not about drying, it´s about getting the smear and dirt etc. off the PEI sheet mechanically.

I use a small Bosch akku powered sanding tool to rub a fresh sheet of kitchen paper towel across my smooth PEI sheet for about 10 seconds after washing the PEI sheet and then after every print again with some alcohol on the paper towel.

Regards

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Recent extrusion and adhesion issues - unable to print anything successfully

I really appreciate all the suggestions. I started going through them in a methodical manner.

I washed the bed with soap and water for good measure.

Jeff Jordan's live Z cal is what I had used previously to establish the first layer height for the powder coated steel sheet. I switched to black Prusament PETG (what came with my MK3S upgrade kit) just to use the most trustworthy material I have on hand.

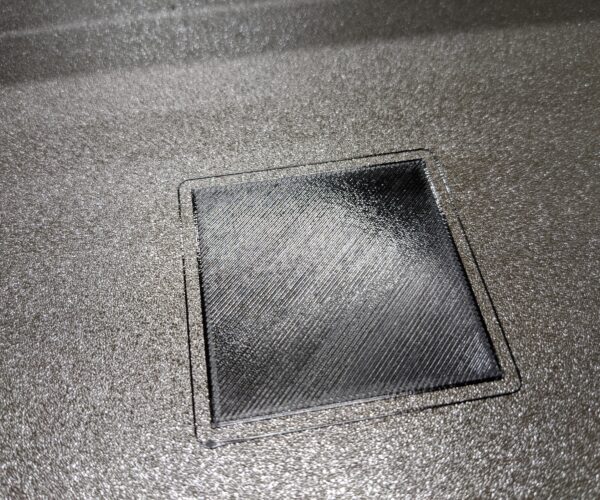

I re-printed the JJ calibration square without changing anything, and it looked pretty good - though I did notice that after peeling it off the bed, I could see pinpricks of light through some areas.

I ran the hotend PID calibration routine via the menu on the printer, and then re-printed the calibration square, again without changing the Z height at all. This time it looked even better, and holding it up to the light it's completely solid - to my eye, it looks more or less perfect.

I then printed a benchy using the built-in Prusa PETG settings in prusaslicer. It printed to completion and looked pretty good, though the finish was dull - and it turned out to be extremely brittle. I happened to drop it on the floor and it broke into three separate pieces, and I found I was able to tear apart the layers by hand. Clearly the layer adhesion was not good at 240C.

I printed another benchy at 250C and it looked better - more glossy and it's not nearly as fragile, however I was still able to crack it along layer lines by hand with some force.

I'm currently printing another one at 255C as the next test.

In all of the above tests, I had no problems with bed adhesion - even the skirts around the prints laid down clean and stayed stuck down.

My tentative conclusions thus far are that:

A) The PID calibration made a huge difference

B) I seem to be needing to print 10+ deg C hotter than I ever had to in the past - this makes me wonder whether my hotend temperature sensor has developed a bias error over time, which could explain why the overall performance has changed unexpectedly

Thanks again for all the advice. I'm going to keep experimenting with it, and may try the "reset everything and start over" approach if I encounter any further issues during testing. I'll hold off on marking this as "Solved" until I've really put it through its paces, but I'm much more optimistic now than I was a day ago!

RE: Recent extrusion and adhesion issues - unable to print anything successfully

What was the bed temp for the benchy?

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Recent extrusion and adhesion issues - unable to print anything successfully

Also clean bed with dish soap, water(hot), if you change filament, pla to petg.

PLA sticks less on powder coated bed, on pei it should stick better.

A few prints you can clean with alcohol, then use dish soap again, except for big flat, small prints, these need a lot of sticking.

Also firts layer is important for to get better sticking.

RE: Recent extrusion and adhesion issues - unable to print anything successfully

I am currently printing all PETG prints at 90C bed temp, including all of the test squares and benchies mentioned here. I have not experimented a lot with other values for bed temp. That's the default Prusa PETG bed temp value so it seemed safe - I haven't seen recommendations to go any hotter, but a lot of guides seem to suggest going down to more like 70C. I'm willing to try changing it if that's advisable - I've just been more focused on the bigger problems I'd been having in upper layers rather than the first layer.

Below is the calibration square I printed before the PID tuning. I didn't get a picture of the one printed post-PID-tune, but suffice it to say that it looked similar but with none of the small pinholes visible where the diagonal fill meets the perimeter. When peeled off the bed, the post-tune square is a strong, continuous sheet - I am unable to tear it apart along any of the diagonal lines

RE: Recent extrusion and adhesion issues - unable to print anything successfully

Think you need to go lower.

RE: Recent extrusion and adhesion issues - unable to print anything successfully

Try printing hotter and slower.

RE: Recent extrusion and adhesion issues - unable to print anything successfully

I just printed the following two parts at 260C hotend, 90C bed, 5mm^3/sec max volumetric speed (which is about 1/3 slower than the Prusa PETG default). No warping, no crashes, no failure - some minor cosmetic imperfections perhaps, but they are nice and strong.

This is a complete turnaround from where I was earlier this week - thanks everyone for all the assistance!

I will continue to experiment with bed temperatures and print speeds to see if I can dial it in further, but for now I'm thrilled to be able to actually reliably print parts again.