PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

PrusaSlicer is creating disconnected line segments, and its drawing straight lines that waver. Plus, it is refusing to close one square that is closed on the STL file.

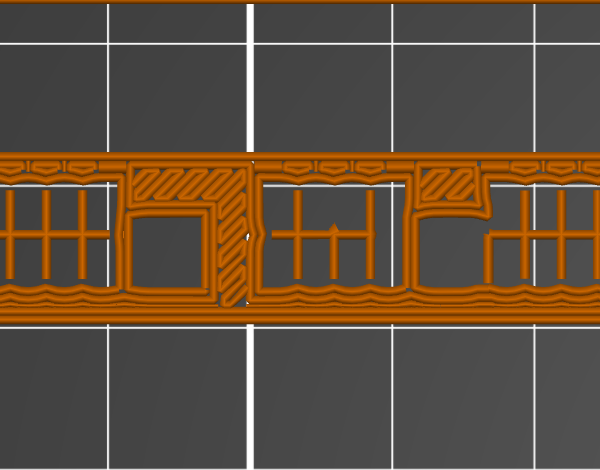

This file shows the first layer. You can see:

- The squares are not square, and they should be.

- Many disconnected line segments

- All lines should be straight, but you can see they are curved.

- Completely missing line segments (look for the grid, where the grid is actually missing segments.)

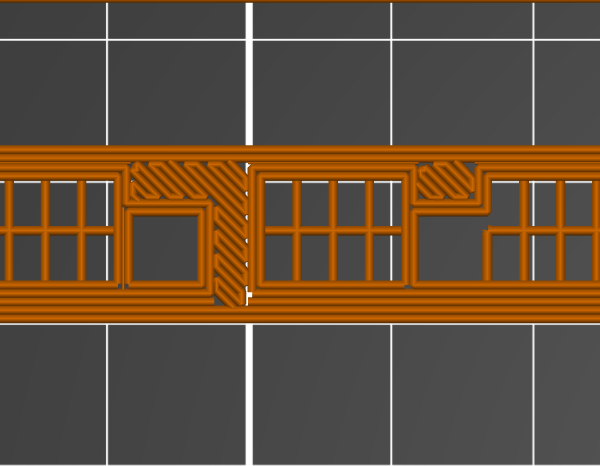

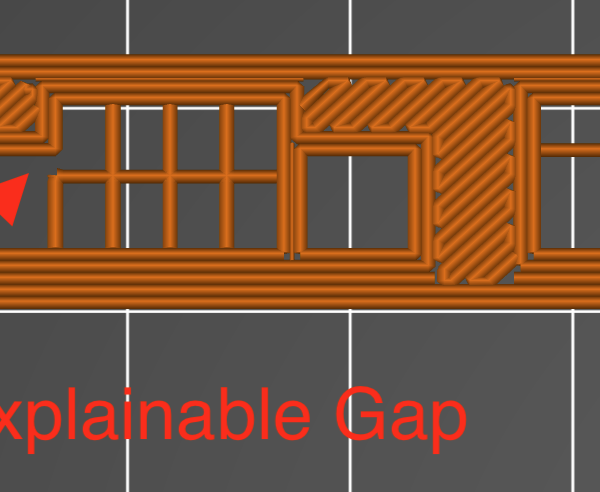

Here is the second layer. You would expect it to basically look like the first, as nothing changes between first and second layer in the STL file. But it is quite different. The lines are now straight and the grid is closed. However, there is still an error where the right-most large empty box still breaks through to the smaller box in the grid. It shouldn't be doing that.

It's quite possible that I have some settings wrong, but I cannot imagine which ones.

Any help would be appreciated. The STL file is attached.

RE: PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

So many design errors ... your STL is broken. Plus, there appears to be a chamfer on the 'windows' that are having issues. Again, something off in the actual design. There are some odd voids, too. Almost like (guessing here) you've inverted some faces and normals. it's been a while, but I've seen this before using models for plane wings and fuselages: there is a setting that needs to happen in the design software... been too long, but search the forum for airplane models, I think it was Voj who finally found what was happening.

I think this is the thread: https://forum.prusa3d.com/forum/prusaslicer/slicing-rc-plane-wing/#post-163772

RE: PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

Yikes - it's simpler than that: Elephant Foot Compensation seems to not like your model. Try setting it to 0.0.

You should also fix the errors in the model. There are lots of them.

RE: PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

Most of the “errors” are unavoidable. Which is why some faces appear to be reversed. I am using zero thickness walls in many cases, and then the option that detects thin walls to force them to nozzle thickness. The reason for this is so that they will be as thin as the nozzle allows, and they don’t need to be changed/edited when the nozzle is changed. I want “as thin as possible” but need to change nozzles occasionally. Since the walls have zero thickness they will inevitably face one way or another.

Agreed, this is unusual design. But it allows production flexibility. And it should not cause the problems indicated.

RE: PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

Elephant Foot Compensation seems to not like your model. Try setting it to 0.0

I will. This is a good suggestion!

RE: PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

Yes! Changing Elephant Foot Compensation to 0.0 fixed layer #1 perfectly.

RE: PrusaSlicer not connecting lines, warbling straight lines, and artifacts of slicing...

Likely something to do with the walls being zero thickness. Hard to have software do what you want it to do when you throw "nothing" at it -- lol -- it can't read your mind. Also, setting detect thin walls doesn't print a minimal 'nozzle width' line; it does more than that.