Prusament Pearl Mouse frustrations

I am having a horrible time printing with Prusament Pearl Mouse and figured it was time to turn to the wisdom of the forums. This is going to be a pretty detailed post. Please read it before you comment or give suggestions. While I realize one should always be polite and gracious when asking people for help, if you suggest something that I explicitly spelled out as having tried, I will politely and graciously make fun of you. 🙂

Quick summary: I'm trying to print some high detail parts in Prusament Pearl Mouse and can't get through an entire print without the extruder skipping -- I'll go into more detail in a bit.

Background: I have a Mk3, built from a kit. Recently overhauled with new X/Y rods and bearings. Hotend was stripped down and checked out. The Prusa heat break was replaced with a stock E3D heat break. First layer calibration done (bed level to under +/-0.05mm). Extrusion multiplier calibration done. Linear extrusion calibration done. Firmware is 3.8.1-2859 (official release). X and Y dimensional tolerance is spot one. On a 40mm cube, one side was 40.04mm and the other 40.00mm. Slicing is being done with PrusaSlicer-2.2.0. As noted, the problem filament is Prusament Pearl Mouse -- brand new spool, fresh out of the bag.

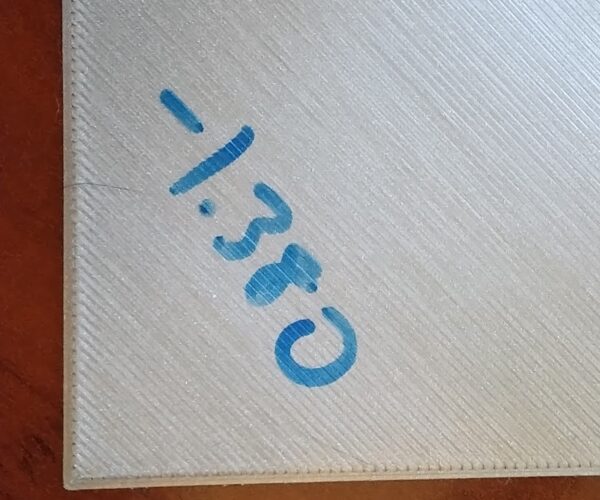

For reference, here is a close up of a first layer calibration square, the bottom of a 40mm extrusion calibration square, and the side of same square.

This is the piece I am printing. This is an earlier, test print, done in Hatchbox Silver PLA with a 0.4mm nozzle and 0.15mm layer height. This is a very old spool of PLA that lives on the printer and is used for random prints. So while there is some variation in extrusion visible, I think most would agree this is a pretty high quality print for PLA filament that's been sitting out for probably six months. This print had no issues at all with the extruder skipping.

Now, to the current problem.

I started on printing the above piece with a 0.25mm nozzle and 0.1mm layer height -- about six and a half hours to print. I used the included 0.25mm nozzle profile and Prusament PLA profiles. I also did and extrusion width check with the nozzle before and found it to be spot on. The extruder skipped here and there, on occasion, but the print did finish without too much noticeable impact on printing, but some definite areas of under extrusion.

An attempt to print three at one time failed completely -- extruder skipping and not extruding at all.

Before I continue. The extruder is NOT clogged in the classic sense. I eject the filament, trim the off the part that has been through the extruder gears, then reload, the extruder primes normally and extrudes immediately. Nor is it an idler tension issue or heat creep from the extrusion motor. In the tripple part print that failed, the extruder gears were doing so well that the filament had "accordioned" inside the extruder tube.

Note that I said the nozzle is not clogged in the classic sense, not that its not clogging somehow. If you look at the above, you can see that it doesn't have anything close to a good tip on it and no sign of the little string you tend to get when ejecting filament from a hot nozzle. Yet I reloaded the filament after trimming that segment and it extruded immediately and normally.

I tried slowing everything down, dialing the print speed down by 50%. That didn't help. I upped the filament temperature by 5deg, didn't help. So at this point, I switched back to a 0.4mm nozzle. I figured I would give up a little sharpness in the corners, but overall it wouldn't impact the final result too much.

Using a 0.4mm nozzle and 0.1mm layer height was worse than the 0.25mm nozzle. I wasn't able to complete a print without enough skipping to serious impact the print quality, or fail the print altogether. I tried upping the print temperature by a 10deg with no luck. I slowed the print speed even further, in the slicer, resulting in a max speed 30mm/s on fastest extrusions. No luck. Dialed back the retraction from the default 0.4mm to 0.2mm -- no luck. In between a couple of failed attempts, I cleaned the extruder and did a couple of cold pulls. This is the one place where I did see something I didn't expect.

When doing the cold pull, I was quite forceful on the filament, keeping it extruding as long as I could, down to between 165 and 170C. What was a bit worrying is the slight ridge where the nozzle meets the heat break. Note that this isn't an untightened nozzle. It was tightened down in the heater block, against the heat break while hot. It doesn't leak. I looked at my 0.25mm nozzle and my backup 0.4mm nozzle have a slight slope on the opening that would seem to correspond to the ridge on the filament.

This, somewhat poor quality crop/zoom shows the slight angle in the nozzle opening.

No such right appears on the cleaning filament when using the same cold pull procedure. However the cleaning filament seems to have a much sharper transition temp. It's either soft and extruding, or not, unlike PLA that gets soft long before it will extrude.

After failing at 0.4mm/0.1mm I switched to the 0.4mm/0.15mm quality profile to see if it would at least print there. I left everything default. It did complete the print, with some very minor extruder skipping on the last few layers. Here is a comparision between the 0.25mm/0.1mm (bottom) and the 0.4mm/0.15mm (top) print.

So now, I'm really running out of ideas. I should note that the extruder skipping doesn't start near the same part of the print each time. Sometimes it starts 20 minutes into the print, sometimes two hours. Sometimes it starts on a wide infill layer, sometimes it starts in the detail parts. I certainly cannot find any common thread.

While I was writing up this post, I decided to try a print with a lower temperature on the though that maybe something about this filament and/or the slower print speeds was letting the point at which it was softening move to far up into the heat break. I went pretty fare down, 200C, from the 215C Prusament default. That certainly didn't work. Only made it 4-5 layers in before extrusion stopped completely. I didn't even eject the filament to clear the jam though. I simply hit the retract button in Octoprint, then hit the extrude button, and extrude it did, and at around 190C too, as the printer was cooling down after I canceled the print.

Tomorrow, I'm going to load up the roll of Hatchbox Silver and see if it will print successfully. The E3D heat break does have a deburring on the throat where it meets the nozzle and the the E3D nozzle drawings also show the throat opening being tapered. Those two would account for the ridge on the cold pull. It lines up perfectly when measured. The melt zone on the above cold pull extends to exactly half way into the actual break section of the heat break -- between the heater block threads and the heat sink fins. So everything I see says the system is operating properly, and yet I can't get a high quality print out of this filament.

Thank you for reading this far and suffering through my pain with me. I sincerely hope you have some major wisdom to share we me, and the next person who comes looking for a solution to this kind of problem.

RE: Prusament Pearl Mouse frustrations

Well, I gave up on the Pearl Mouse Prusament for the time being. I tried the entire temperature range for Prusament, in 5C steps. Tried minimal retraction, tried no retraction. Tried all sorts of speed changes -- though admittedly I didn't try faster than the profile stock speeds. Anything below 0.15mm layers just wouldn't finish the print, and even 0.15mm was iffy. And thats with a 0.4mm nozzle.

So I switched to a new roll of 3D Warhorse Grey that I have. After the extrusion multiplier calibration, it produces most excellent prints with a 0.25mm nozzle and 0.1mm layers. No tweaking of the generic PLA profile needed. This is what I was expecting from the Prusament, not the other way around.

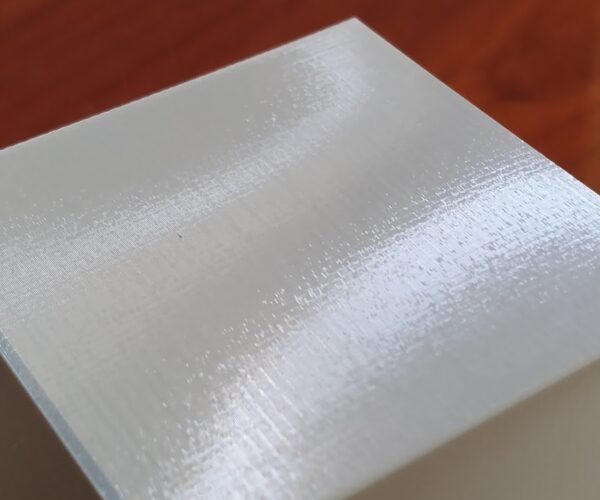

These are photos from the second 40mm calibration cube, after EM calibration -- 0.25mm nozzle, 0.15mm later.

Bottom

Inside

Side

The is the first print of the gate segment that has been my test piece. Straight off the plate.

A couple of close ups, under sharp light and magnification.

It prints so nicely that now you can see the motor drive artifacts in the surface. They aren't really visible to the unaided eye under natural light.

Kinda disappointed in my first Prusament experience. I suppose I should get in touch with Prusa support and see if they have any suggestions. Unfortunately, my printer's busy (and I've only got one 🙁 ), so more experimentation will have to wait.

RE: Prusament Pearl Mouse frustrations

Wow. What a lot of work. I cannot think of anything not attempted other than to note the "ridge or ring" around the filament when pulled. Joel (3DPrinting Nerd) has an excellent YouTube on this very issue. He had issues with one of the new materials from Matterhackers and all of the symptoms and remedials you have gone through were done. Given his trust of the brand and his role as a commentator he didn't want to be unable to review the product or even prohibit himself from using the product. In the end he replaced the extruder/hotend assembly and all was well. I don't know if the change would be classed as an expensive upgrade (super super expensive "I can print 50lt/s and provide comforting music") or simply a change of type. I'm not that knowledgeable yet. I suppose at the end of the day, judging from what you clearly can make, it comes down to whether you wish to use this filament or not.

If I find the You Tube URL I will post it.

Andrew

That said his solution was to pretty much replace the extruder. Your options therefore appear to be

RE: Prusament Pearl Mouse frustrations

@william-m51

I have to agree with you. I have been having a horrible time trying to print a fine detail item in Pearl Mouse using a 0.25 nozzle. I haven't tested to anything like the extent you have but I've done lots of samples. Some improvement if I print at 235 C and very slow but it's not right. I changed to Galaxy Silver and instantly got an improvement as seen in the photo (Same settings, Mouse to the top. Note the 'dry' appearance of the infill). I've had some good prints with Pearl Mouse using the 0.25 nozzle where the part had very little infill - it seems the infill is a problem with this material.

RE: Prusament Pearl Mouse frustrations

You could try to cool down the extruder motor, use a computer fan or table fan, to hit the upper part of the printer,(to test)

or print a extra fan holder on the extruder motor, to blow air to the top of the printer, on thingiverse there is a model.

If this does not help, I would change the heatbrake, to e3d heatbrake, the 3ed is smaller(this is standard).

I have a mk3(no s) and i did the extra fan on extruder, and the heatbrake I change, after that I had no problems anymore.

And leave doors open of enclosure for pla, or if it is to hot in the room.

RE: Prusament Pearl Mouse frustrations

@peter-m26

Peter he already stated he has a standard E3d heatbreak fitted.

RE: Prusament Pearl Mouse frustrations

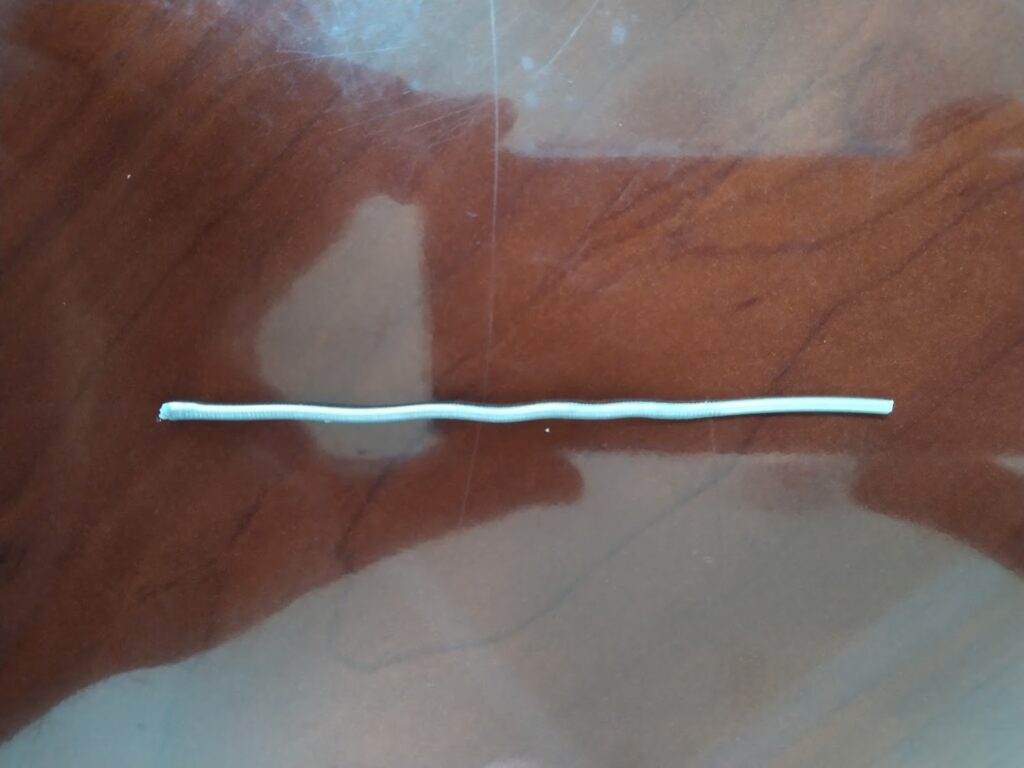

I wanted to circle back to this, as I have identified the likely culprit.

The left is the PTFE tube I had installed in the hot end. The right is new PTFE tube from Prusa. Some time ago, actually a very long time ago now, I had replaced the PTFE tube in the hot end. I ordered, what I thought, but failed to check it against the tube I was replacing before installing. As seen in the picture, the inside diameter was definitely NOT correct. This explains how I was able to get filament that looked like this.

I need to go back and try and print some things with the Pearl Mouse Prusament now. I expect it to print much better now. The old roll of white Prusa PLA, that is currently on the printer, would start skipping on prints that had lots of retracts. The change seems to have fixed that.