Prusament brand new spool, bottom of print failed

Hello,

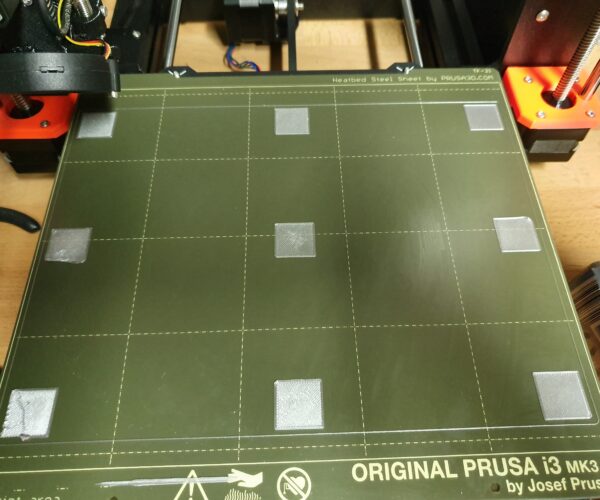

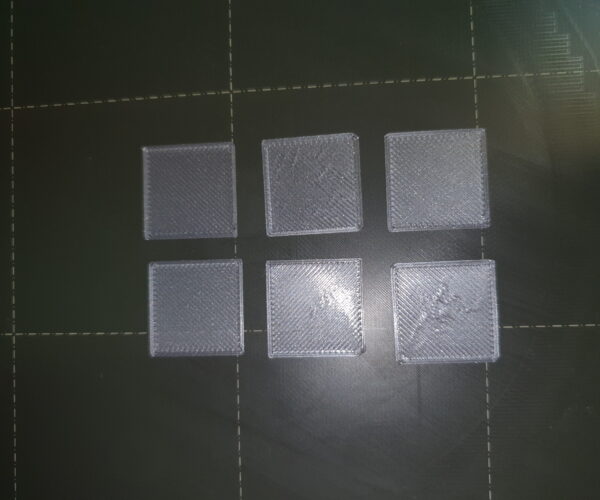

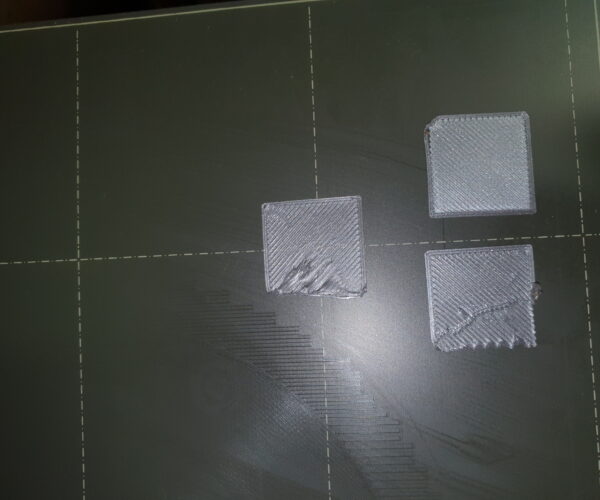

I had just finished a 12h51min print, and found out that the bottom of my print, failed somewhat, also on one side there is a bit of warping.

Here are some pictures:

Today I'm printing something else, for the moment all seems ok.

Do you guys think this was a one time thing ?

Maybe something wrong with the beginning of the new spool or something ?

Or somerhing to do with the infill pattern ( grid ) ?

Print settings where:

Layer height 0,15mm speed

Infill 15%

Thanks in advance.

Greetings,

ilja

RE: Prusament brand new spool, bottom of print failed

- Almost forgot, on the one picture with the warping, above the warping failed a bit as well, but that's my fault, I only choose support on the printbed.

RE: Prusament brand new spool, bottom of print failed

Also on the printbed, there were a few microscopic print lines still attached the printbed ,

was a bit hard to remove them with the isopropyl alcohol.

RE: Prusament brand new spool, bottom of print failed

Busy with the new print, just saw that the printer wasn't printing anything it seemed.

Then I heard a clicking sound once. I pushed the filament down and then he started printing again.

It was the top layer he was printing.

So also a problem there.

So I should thigten the screw or loosen the screw of the filament door ?

Before, I've printed with the Silver PLA that came with the printer, with Orange PETG and Prusament Gentlemen grey.

Never had this problem.

Thanks in advance.

Greetings,

ilja

RE: Prusament brand new spool, bottom of print failed

Looks like the Z offset might be a touch high. If it still works after a food first layer, consider an adhesion promotor.

I use three different ones regularly with good success. I use a glue stick, Layerneer Bed Weld, or Aquanet Hair Spray.

--------------------

Chuck H

3D Printer Review Blog

RE: Prusament brand new spool, bottom of print failed

I ignore posts where the user can't or won't post the images on the forum.

RE: Prusament brand new spool, bottom of print failed

@tim-m30

There's a link with pictures in the first post.

In the past I've put pictures directly in a post,

but the forum makes them stretched, so that's why I put them in a link,

so you can see them as they are and not stretched.

RE: Prusament brand new spool, bottom of print failed

@charles-h13

Apart from the bad top layer, the print came out fine.

Then I've started a third print, it started printing so I thought it would be ok,

but after 15 minutes I went back to see, and it wasn't printing anything.

I think now the nozzle is clogged. Because I've tried to get some plastic to extrude and nothing happens,

I do hear some clicking. I've tried to loosen the screw and also tighten it.

Not sure what elso to try.

RE: Prusament brand new spool, bottom of print failed

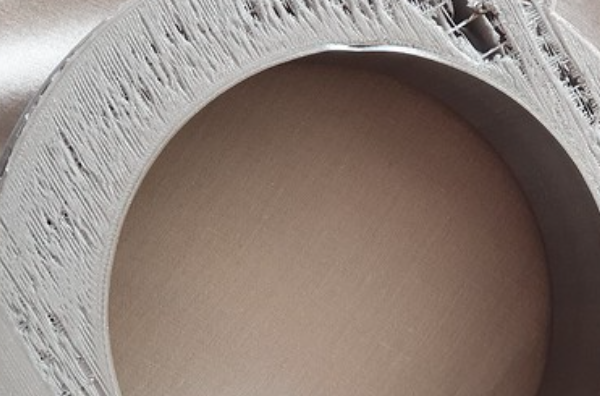

Hopefully the image isn't stretched.

This is the finished second print with bad top layer (large bottom circle)

Edit: the image is stretched, told you that the forum does this

RE: Prusament brand new spool, bottom of print failed

The preview image is distorted but looks normal when you click on it (as long as LINK TO MEDIA is selected). In every case better than links to third party sites that often aren't there a week from now.

The flat surface has a ripple. Is that your concern? That is generally bad layer 1 adhesion, or perhaps slight over extrusion. Nothing else about the print looks "bad" in the classical sense of a failed print.

RE: Prusament brand new spool, bottom of print failed

Poor part design - or - printing a part that requires supports, without them.

Printing a part on a dirty / contaminated print surface combined with a poor layer 1 / Live-Z calibration.

ps: this also might be a partially clogged nozzle ... or a combination of all of the above.

RE: Prusament brand new spool, bottom of print failed

@tim-m30

The printer wasn't printing on that top layer whenI went to see it, and then I heard a clicking sound.

It was halfway on that top layer, as you can see in the picture, when I pressed down on the filament,

and then it started printing the other half ( right side in the picture )

In other news, I've managed to unclogg it. But maybe some Live Z adjustment is required I guess for it to print normally.

( at least with this Prusament filament )

RE: Prusament brand new spool, bottom of print failed

Clicking is usually the extruder trying to force filament through a clogged nozzle. Many causes, but verify the hotend is at temperature; do a cold pull to remove old cooked filament residue; ensure adequate Bondtech idler tension.

RE: Prusament brand new spool, bottom of print failed

Ok, so I noticed something strange. in the menu it said "Sheet Texture 1", that's really strange, it's supposed to be on "Sheet Smooth 1"

I've changed it to "Smooth 1", hoepfully that fixes it, but I wonder how it changed to the textured sheet.

I've only ever used that sheet to do the calibration. Weird...

RE: Prusament brand new spool, bottom of print failed

Poor part design - or - printing a part that requires supports, without them.

Printing a part on a dirty / contaminated print surface combined with a poor layer 1 / Live-Z calibration.

Indeed, only choose support from printbed, my mistake LOL

I always clean my sheet with 91% isopropyl alcohol before printing.

Posted by: @tim-m30

ps: this also might be a partially clogged nozzle ... or a combination of all of the above.

Was clogged indeed, but that's fixed.

RE: Prusament brand new spool, bottom of print failed

Can you edit live z-adjust inside prusa slicer or only on the printer itself ?

So I can adjust the prusament profile perhaps ?

RE: Prusament brand new spool, bottom of print failed

@ilja-coveliers

Can you edit live z-adjust inside prusa slicer or only on the printer itself ?

What does the manual say?