PRUSA MK3S+ Banding issues

Hello Everyone

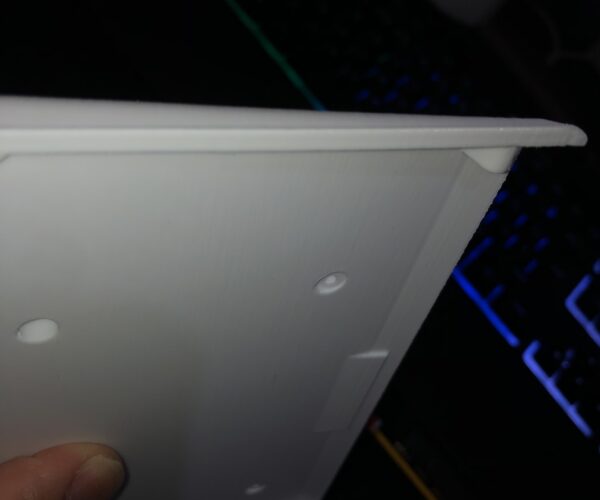

I'm new to 3D printing and I bought my MK3S+ just a few months ago, I mainly use my Printer for printing RC models as I'm an Avid modeler and so far I am very happy with my Prusa...Until now that I'm experiencing Banding problems or at least from my poor experience in 3d printing, it what I think is the problem.

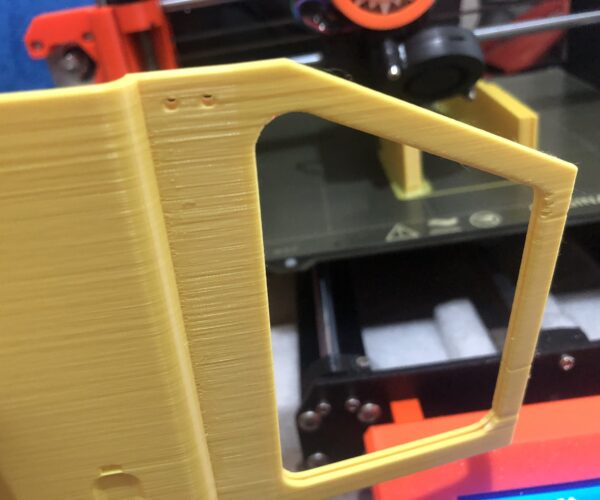

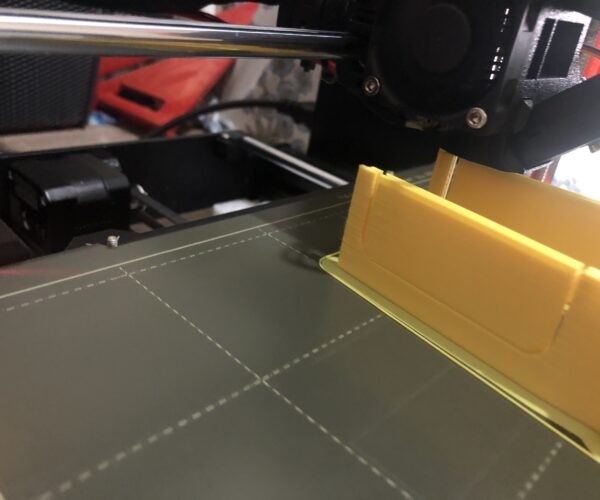

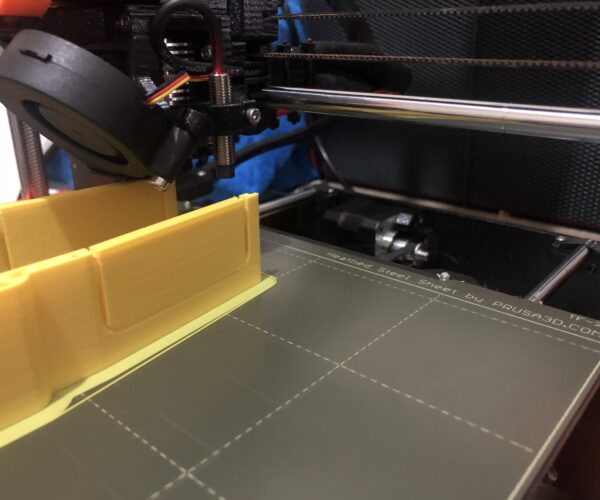

I'm printing a Landrover model from 3D sets and so far most of the parts printed came out very nice, I'm using Gembird PLA+ Yellow Filament for most of the parts. I was printing what is supposed to be the left door and I noticed a lot of defects across the pillar, this door is printed vertically with supports and the G-CODE that I use is for the mk3s.

I checked for loose bolts or connections, belt tensioning, obviuos damage on the x and y axis Rods, I also recalibrated the printer including the Z height which is at -1.450. everthing looks to be within spec and every test I made from the LCD passed.

What might be the Culprit for this problem? the prints are starting to look really messy. can it be maybe moisture with the filament? or just bad filament? if you notice from the photo's I'm printing another Set and the Banding seems to be a little bit less after I checked and recalibrated the printer but its still there. the first door that i printed which is shown in the photo's I printed it alone.

Can anyone please help me out?

Regards

Daniel

Couple of thoughts ...

Looks like you improved the variation considerably with the re-tuning you did. I find the printers are prone to showing these types of defects the longer you go between tear downs and re-lubes. Small friction and play allow/cause the nozzle to wobble layer to layer. Check that your bearings are gliding smoothly over the rods (use control panel to disengage steppers to check this). Check that your X back carriage plate is not overly tight, but not so loose that the bearings can wiggle in their races. Also, check your bed plate. On my newest printer (3 months old) I found the bed had a lot of vertical play and it turned out that the NYLOC nuts used to attach the bearing holders had all deformed (the plastic that should be holding the screws tight had all squeezed out of the nuts (poor quality nylocs). Tightening those eliminated the bed play and my print quality returned.

PRUSA MK3S+ Banding issues

Thanks for your kind feedback, I thought nobody would post. Excuse my ignorance 😳 and for the stupid question, but when you referred to the X back Carriage plate you were referring to the back of the extruder? I checked also the bedplate and everything is well secured and there's no play on the bearings that hold the bedplate either plus as suggested I also checked that the bearings are gliding smoothly over the rods by pushing the printed bed and extruder, everything moves smoothly. now I'm printing another piece but this time from PETG to see if it makes a difference with different materials.

@daniel-cardona

Hi Daneil,

I believe you may be experiencing a problem that is associated with wall thickness and the extrusion widths you are choosing. its possible the part is moving a bit as it is tall and thin however in my experience and based on the images provided this really shouldn't be the case.

Maybe this Thread will offer some insights, Lines and bulges in printed object

if you need more help please consider uploading a Zipped up .3mf file exported from Prusa Slicer.

Note:the server will only accept the file if its zipped.

Good Luck

Swiss_Cheese

The Filament Whisperer

go with Cheese for my money

I was thinking of the same thread, Swiss.

PRUSA MK3S+ Banding issues

@daniel-cardona

if you need more help please consider uploading a Zipped up .3mf file exported from Prusa Slicer.

Note:the server will only accept the file if its zipped.

Good Luck

Swiss_Cheese

How do I do that? sorry for all my questions, I'm so new to this 3d printing stuff. I printed a few thin wall models with success using mostly supplied G-codes. I rarely print from 3mf files unless I need for example only one specific part like this example I needed to print only one Door as I knew I didn't have enough material in the spool to print the entire G-code ( two doors at the same time).

Zipped up .3mf file

here is what I was trying to print.

zip file

dang! I tried to attach the file but it didn't work, The maximum allowed file size is 10MB, How can I attach the file here?

Right click file, send to... compressed folder

And use the button below the text entry box. Choose File.

@daniel-cardona

When I look at the pictures it seems that the problem start near bottom of print.

Is it possible to cut the part at e.g. 40mm height?

And then save, zip, upload. It should produce a smaller file

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

PRUSA MK3S+ Banding issues

Hi everyone, sorry for my late reply.

Is there anyone willing to let me send the file to your personal e-mail? I cannot compress the file which is 186kb to 10MB, I don't know if it's even possible.

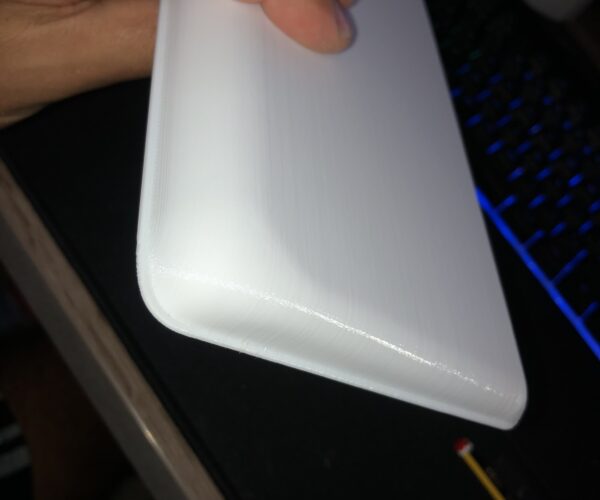

BUT, yesterday I printed another part for my model RC Landrover from 3Dsets which is the Rooftop. The G-code supplied was meant to be printed with PLA but I wanted to try to Print it with Esun PETG, So I used the STL file instead and used PRUSA Slicer with the generic PET settings. the only settings that I touched were the Temperatures and brim. I used 150 extruder temp and 90 deg temp for the first layer and 140deg and 80 for the rest.

the print started OK but of course, I started to see the banding reoccurring, and maybe after 1 hr or less the unexpected happen. The print warped and began to detach itself from the bed 🤬.

anyway...after a bit of unnecessary cursing I clean the sheet bed, applied some gluestick, and made a quickly improvised enclosure consisting of the Esun filament boxes and a garbage bag 🤪 , but hey it worked.

So after 10 hrs, these are the results

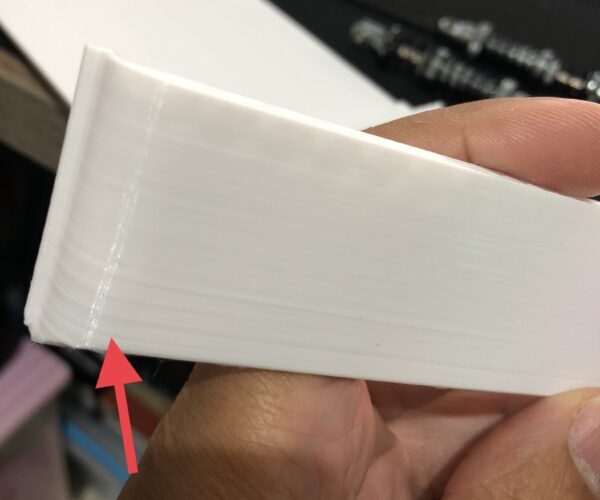

the first printed part which warped :

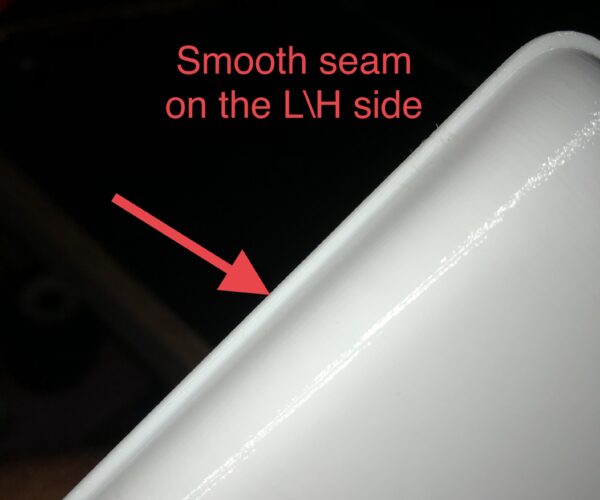

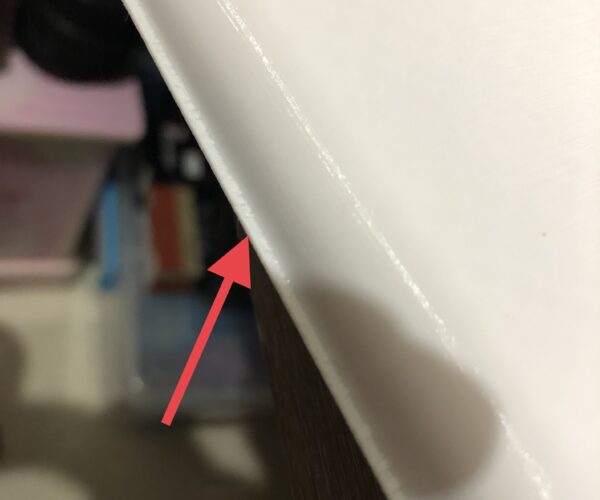

As you can see the banding is mostly on the lower part up to 30 or 40mm then after that on the completed part it went more or less smooth, totally different story when I printed the doors shown in my previous photos. Note that at the bottom there was a sacrificial support part that must be detached after the printed part is ready, so this roof is printed vertically.

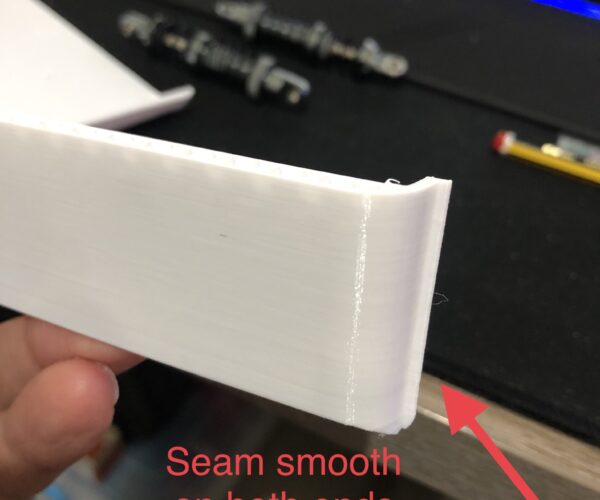

I also noted that the seam or whatever it called on the landrover rooftops which are at the edges on one side is smooth and on the other came a bit rough but on the defective part it's smooth on both sides.

could be the enclosure help to reduce the banding or it doesn't matter?

anyway...I have to figure out how to post that file.

regards

Daniel

PM

You've got PM

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

His file

Here is his file

Don't know why it didn't work for him

This is @daniel-cardona 's file, I didn't do anything with it, just zipped it and upload it

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

@ringarn67

Oh thank goodness, how might this explanation go?

The Filament Whisperer

PRUSA MK3S+ Banding issues

thanks! I was using WinRAR and 7zip but I couldn't compress the file to 10MB.

Just a heads up,

For those working towards the betterment of Daniels slice, I have done a first pass on it and adjusted extrusion widths and fill, there is a support part missing near the door latch I have remodeled and added into the tuned version of the .3mf, I'm currently running a test and will post when done.

To whom it may concern, its a long test, so feel free to share whatever you have at anytime.

Enjoy

Swiss_Cheese

The Filament Whisperer

How to zip

@daniel - in windows file explorer, right click the file to be zipped, then select send to ... and then select compressed folder. This is how you zip a file using windows commands.

zip file

success! I was trying to attach the file using the ''choose folder'' instead of ''add media''. 😔 🙃

You popped your Cherry !

Congrats on your success, 😀 I can still remember my first Zip, like it was yesterday.

I printed your Model last night 17 hour print, one door tuned, and one not, and for sure the tuned version is superior quality, however I identified a couple other issues with the model and am going to print only the tuned Door again with the changes for those issues in mind. so another long Print before I post results. But sufficed to say that extrusion width adjustments are needed.

We're sacrificing a goat in another Thread 🤫 , so I'm sure new adjustments will all work out.

Anyway I'll be back after, Happy Halloween!

and remember, Keep your Zipper up.

Swiss_Cheese

The Filament Whisperer