Printing tiny gears (3mm-1cm) from nylon

Hi All,

I received my MK3S over the weekend. I put it together, self-test, and calibration went smoothly.My first print was the PLA Prusa tag, where I further adjusted Z height when the first layer was printing. The second print was the benchy which came out perfectly. Very smooth surface, nice bridges. Benchy’s height was 48.1mm, 0.1mm over than what it supposed to be. I’m perfectly OK with that.

I’m very impressed so far.

I’m planning to print a mini gearbox for pager motors from nylon (Taulman Bridge maybe?)

Taulman recommends ambient temp. between 30-100C.

http://taulman3d.com/bridge-nylon.html

I have a couple of questions:

1. I’m only planning to print max 5mm height gears, do I still need an enclosure to bringup the ambient temperature? Or I can get away with just heating the bed to 50C for example.

2. For tiny gears would it make sense to switch the nozzle to .25mm or the default .4mm will handle the small details? Hopefully the Bridge filament will handle the smaller nozzle.

Thanks,

James

RE: Printing tiny gears (3mm-1cm) from nylon

anyone has experience with small gears?

thanks,

James

RE: Printing tiny gears (3mm-1cm) from nylon

Hello James,

I've printed already couple Nylon gears.

1. For small gears it might work without an enclosure. Heat up the bed to 90C, use glue stick. In under 30 Minutes print time you might be lucky and the part will not warp. But make sure the ambient temperature is as constant and as hot as possible.

2. It highly depends on the gears. You can easily simulate different nozzle sizes in the slicer and check the result. In general smaller nozzle diameter can give you sharper corners. But 0.4 nozzle diameter can you give you already pretty nice results. This is part of try, check and repeat.

Hope that helps.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Printing tiny gears (3mm-1cm) from nylon

Hi Nikolai,

I didn't realize that I could check the details with the slicer - good suggestion.

Thanks for your feedback,

James

RE: Printing tiny gears (3mm-1cm) from nylon

I print gears for clocks and have done a bit of experimenting with various sizes. Something on the scale of a pager motor might be a bit of a challenge for any FDM printer. An SLA printer might be a better choice if one is available to you.

Nikolai's suggestion to check the slicer results is a great idea. You want the gear teeth to be formed using a continuous string of filament. The picture shows a portion of a 54 tooth gear at different scales. The left gear is 33.5mm in diameter and the right gear is 17.8mm in diameter. Everything uses the default settings of PrusaSlicer with a 0.4mm nozzle. Notice how the left gear has a small white line of gap fill in each tooth. This will cause multiple retractions which increases the likelihood of a small blob of filament ending up somewhere on the gear. The gear on the right is formed using continuous flows of filament. It will produce a much smoother gear. You may need to adjust the gullets to make them deeper and make the rim a bit wider.

Changing to a smaller nozzle should allow smaller gears to be printed. Keep going back and forth between your CAD program and the slicer until the gear looks good. You may find that properly adjusted gear teeth have plenty of strength with PLA.

RE: Printing tiny gears (3mm-1cm) from nylon

@steven-p8

I know I’ll be pushing the printer’s capabilities with the small gears.

I used make parts with +/-.025mm tolerance with a CNC machine. I’ll never achieve that with the printer but hopefully I’ll get close. Of course CNC had its own issues with creating fixtures and constant tool changes.

3D printing is so much more convenient. Thanks for posting the pic. I didn’t think about avoiding gap filling, but it makes perfect sense. I’ll use PLA first to get familiar with the process.

I was looking into SLA but I didn’t think SLA would print durable parts.

Thanks,

James

RE: Printing tiny gears (3mm-1cm) from nylon

I was looking into SLA but I didn’t think SLA would print durable parts.

It's time to look again 🙂

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Printing tiny gears (3mm-1cm) from nylon

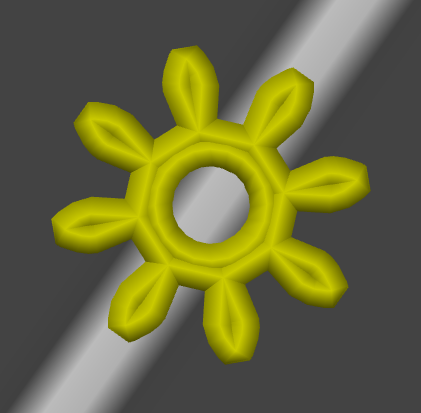

As a note, I generated as small a gear as I reasonably could. It has a 1mm bore, with 8 teeth and an 80mm circular pitch.

With a 0,40mm nozzle, you get two continuous perimeters that make up the gear and teeth.

Not sure about the mechanical strength of such a gear. Success in printing it and it being usable is going to be highly dependent on the tolerances of your printer.

RE: Printing tiny gears (3mm-1cm) from nylon

The SLA suggestion was based on the fine detail that can be achieved. That resin looks like a great option.

Also note that gear teeth roll past each other with very minimal rubbing. My clocks have been running continuously for about 10 months with no noticeable wear on the gear teeth. Even the escapement still looks perfect and it is the only surface with sliding friction in the clock. The clock has ticked nearly 40 million times in 10 months. It is printed in generic PLA.

Steve

RE: Printing tiny gears (3mm-1cm) from nylon

@william-m51

That gear looks great. Print one in PLA and see how strong it is.

Steve

RE: Printing tiny gears (3mm-1cm) from nylon

@william-m51

That gear looks great. Print one in PLA and see how strong it is.

Steve

Caveat -- I haven't calibrated my printer in a while, nor have I updated firmware to get the newer bed leveling code. I'm sure I could get better with some effort, including using a 0.25mm nozzle rather than the 0.4mm one I have installed. In trying to crush it with a pair of pliers, I would say its as strong as I would expect any gear of that size to be. Printed in nylon, it might actually be functional though I expect the wear would be high and you would probably want to print in nylon.

RE: Printing tiny gears (3mm-1cm) from nylon

@william-m51

Now that is small!

Another question is how balanced the gear is. With small motors the RPM can be high. With a 50K RPM motor at the first 5:1 reduction the RPM is still 10K.

Installing a small gear on a 1mm metal shaft can be challenging. If the gear is unbalanced the whole gearbox would vibrate. I’m thinking about securing the shaft on both sides and install a 1x3x1mm ball bearing into the gear. The gear will have a large and a small gear to provide further reduction. I’m trying to build a small gearbox with an encoder for small robots.

RE: Printing tiny gears (3mm-1cm) from nylon

Maybe you need to increase the minimum time per layer to allow the part to cool a bit. It looks a bit squished. 🙂

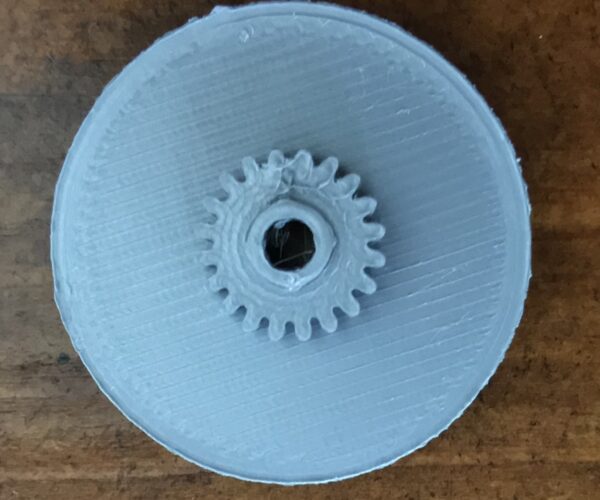

Here is my attempt at getting a small gear to print. The gullets were made a bit deeper to help prevent binding. Pictures are attached. The original gear in CAD is in black and the updated version is red. There is no backlash in the original design, but a printed gear would need some backlash. The pinions have no room to add backlash, so a small amount was subtracted from the larger gears. This has a double benefit. It adds some backlash. It also reduces the tooth width enough to eliminate the gap fill.

The first picture is the CAD diagram. The next is the slicer result. The final picture is the end result next to a US dime (our smallest coin). The gears mesh reasonably well, but might be better if they were around 10% larger with the same tooth size and slightly more backlash.

Steve

RE: Printing tiny gears (3mm-1cm) from nylon

Maybe you need to increase the minimum time per layer to allow the part to cool a bit. It looks a bit squished. 🙂

RE: Printing tiny gears (3mm-1cm) from nylon

Hello All,

I`m trying to print also tiny gears, 11 mm outside diameter, 3 mm height. I'm having issues printing them. Four of 20 teeth don't get the right shape. Please check the images. The issue seems to be aligned with the Y-axis motor and/or the beginning of the nozzle layer. It could be an axis positioning issue due to backlash. Do you have any suggestions for compensating or achieving a better shape?

Material: PLA Nozzle diam: 0.40 mm Layer height: 0.05 mm

RE: Printing tiny gears (3mm-1cm) from nylon

Looks to me like it deforms because of the heat. Try to slow down the print. Layer height of 0.2 is better for mechanical parts than 0.05 as-well.

Picture of the slice would also help to understand how it‘s being printed.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Printing tiny gears (3mm-1cm) from nylon

I often find that quality improves with reduced speed.

Unfortunately FDM printing will always have a seam, either alighted or random.

This may well be one of the few/many (you pick) situations where resin (MSLA) printing is superior.

RE: Printing tiny gears (3mm-1cm) from nylon

.25mm nozzle helped.

After lot of experimentation, the proof of concept is working with PLA. (how nylon is going to print with .25mm nozzle is the big question)

(scroll to the bottom)

http://nagycnc.com/3d-printing/

Shaft quality is an issue too. Using small steel shaft would wobble eventually. I ended up printing bigger shafts.

Printing Tiny Gears

I also use a smaller diameter nozzle. I found that reducing the acceleration on perimeters helps. The build plate is heavy and the belt stretches more in one direction due to the longer length in tension. This gives the teeth pointing towards the back a deformed tip.