Printing problem

I have problem that my Prusa prints about 5cm high and after that it just stops feeding the filament. Its running normally but without printing. Its done it now few times with different prints. There is not any errors find in log. Anyone can help?

RE: Printing problem

Prusa Knowledge Base | i3 Printers Regular Maintenance (prusa3d.com)

Could be the extruder needing adjusted/cleaned, maybe run through extruder procedures in this, particularly the bondtech gear alignment and cleaning, and make sure the pressure is correct.

Prusa Knowledge Base | Clogged nozzle/hotend (MK3S, MK2.5S) (prusa3d.com)

Could also be a clogged nozzle.

Have you changed nozzle recently?

What filament are you running, whats the temps?

Tank you very much!

RE: Printing problem

@clarmrrsn

I run PETG Prusament in 240/250 temp. I think extruder is clean as after failure if I start printing again everything works normally and printing quality is good.

I have not changed the nozzle.

RE: Printing problem

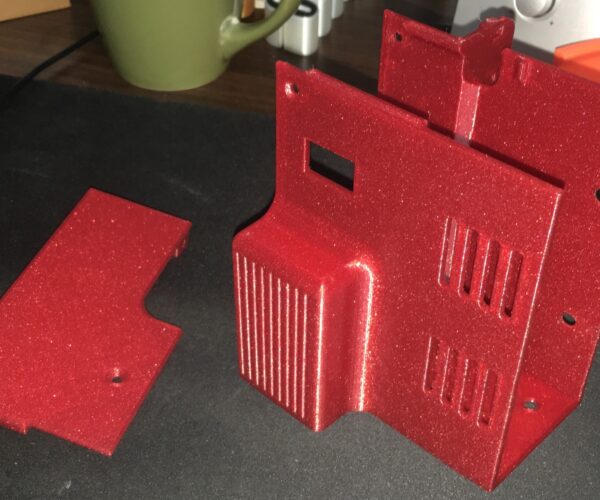

Printing always stops about same time, between 6 and 7 hours. I changed filament to PETG Prusament carmine red and then the problem starts. There is a bit glitter in carmine red so that might be stuck the nozzle during long printing. I try with standard PETG Prusament black next and Im pretty sure the problem is solved.

RE: Printing problem

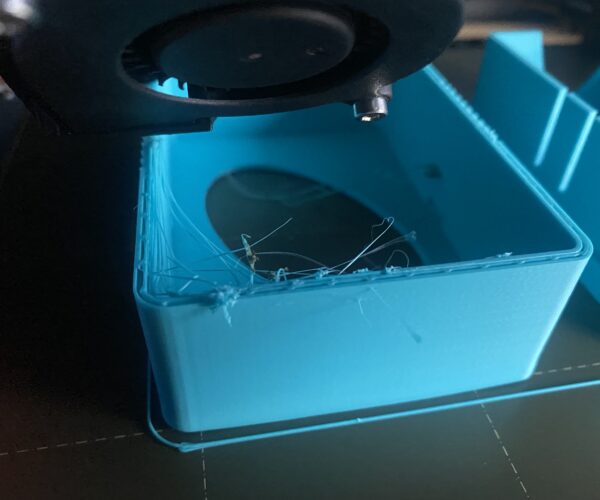

This machine is totally pain in the ass! I have now cleaned the nozzle and hotend many times, changed to different filament, tried with lower temp and every time the result is the same! When try to print larger object it stops printing after it goes about 5cm high. Filament is not coming out from nozzle. When start again new print after stopping all works ok. Here is one picture of disaster printing. What should I try next? Buy VW Polo radiator fan and add it blow next this machine?

RE: Printing problem

@teemu-anttila

If it is a thermal problem you will see a difference in time to failure when starting from cold against starting again straight after a failed print when everything is already hot: but heat issues usually occur in less than 6 hours.

You say it manifests at the same height every time, does this happen even when you print a tall narrow part and get to that height in a shorter time?

I don't see much stringing, I would expect to see more if your filament was damp - listen to the nozzle, does the filament make slight fizzing and popping sounds? If so try drying the filament.

Cheerio,

RE: Printing problem

@diem

Hi. I print the tube that was 10cm high and it takes 1h 38min without any problem. Now I try with table fan next to the printer... lets see...

RE: Printing problem

I get the printing done. I use temp 240/85 and extra table fan next to te printer. Not any problems.

RE: Printing problem

This machine is pain in the ass. The problem is not solved I just was lucky to get that one printing done.

I have tried 4 different filament, from 220 to 250 nozzle temp and result is always the same. I thought this is not any Chinese shit printer but I think I was wrong. If someone knows what to do Im more that happy to hear.

RE: Printing problem

I would suggest speaking to Prusa Tech Support via EShop Chat.

Tank you very much!

RE: Printing problem

@teemu-anttila

I would like for you to post a Zipped up .3mf file of the head phone stand with the settings you have been using, this will allow me to see your project as you have been trying to print it, and is the fastest way for me to diagnose the possible issue. you can do this by opening the project in slicer setting it up the way you have been and then selecting "save project as" from the file menu, and save it as a .3mf then use winzip, winrar or 7zip to zip it up and post it here using the add media button on the forum, it's at the top of the area you type your posts and you can simply drag and drop the zipped up file into the resulting window and post it. I'm not trying to sound condescending with these instructions, however so many seem to have a problem figuring this out that I wanted to be thorough in my explanation. once I have the file I will make the corrections I think need to be made and will upload a revised version of the file for you to try and print and depending on what I find, I will try and offer an explanation of why I changed what I changed.

I am busy at this time so please give me some time to respond before you loose hope

regards

Swiss_Cheese

The Filament Whisperer

RE: Printing problem

Check your extruder gears. If they are loose, and lined up with filament alignment.

Check if grub screw is tightened on gear, heat up extruder, remove filament, open door , then you can see the extuder gears, move extruder so you can see the grub screw.

RE: Printing problem

@swiss_cheese

Hi.

Here are the files that last have failed. All the time quality have been good it just doesn't Finnish.

Printer head is moving and trying to print but nothing comes out.

RE: Printing problem

@teemu-anttila

I've gone over your .3mf files and for the most part they seem to be in order, I did make some very minor changes to improve the print time, the most import change I made was turning the hot end temp up to 260C it was set to 250C by default. I suspect this is why the filament stopped extruding, my experience has been that Prusa filaments need to be printed hotter then their default profiles allow for. areas of the model that print at faster speeds can not only trigger higher fan speeds,(cooling the hot end lower then the specified temp) but can also try to push the filament out faster, if the filament is not hot enough it can cause blockages. sometimes it takes time for this to manifest, TPU is a perfect example of this, it can build a very very slow back pressure in the hot end then stops extruding and blows out the side of the bondtech gears. this can be negated by applying the proper amount of heat and the perfect pressure on the bondtech gears, of course PETG is not going to blow out the side, but it can suffer a similar effect if you don't apply the right amount of heat.

Their can be other causes of this, as mentioned by the other forum members, however if your sure your printer is in good working order and tuned properly then it is likely your printing your filament to cool. as I mentioned above your profiles look good aside from the hot end temperature, and the images you posted seem to show them printing very nicely right up until the filament stops exuding.

So I'm going to recommend trying this profile with increased temperature at least for your pruament PETG's (carmine red for sure) it's important to understand that different manufactures and types of filament will all have these challenges, in may cases it's a good idea to just start with the basic profiles provided with your Slicer, as you learn more it's also going to be a good idea to prepare and print a temperature tower to help you understand the heating needs for each filament.

This is just my best guess as to the problem based on the information you provided, if this doesn't work for you then we will try some other avenue.

Try not to get to pissed off at the machine, their is a learning curve to this and with time you will feel very comfortable using the slicer and printer.

This is the profile I adjusted, pay attention to the print and see hows it's doing as it goes, sometimes this will help you notice important things, and you can use that information to help in the future.

Good Luck & let me know how it goes.

Swiss_Cheese

The Filament Whisperer

RE: Printing problem

@swiss_cheese

Same problem again. Going up with heat didn't help. It stops about after 70% printing.

Filament is not coming out but when I pushed filament down to extruder it starts to print again.

RE: Printing problem

@teemu-anttila

Did you check if extruder gears are not loose, check the grub screw.

Open door extruder, heat up extruder, them move the extruder till you see the grub screw,check if this is loose.

RE: Printing problem

@peter-m

Its checked, all fine in that side.

RE: Printing problem

Another simple suggestion is to check your Idler screw, that's the one that puts the mention on the filament as it passes through the Bondtech gears.

The Filament Whisperer

RE: Printing problem

@swiss_cheese

Checked also that many times.

Now I used 0,4mm retraction.

I tried go extrusion down to 0,95. It jams again about same position.

I have marked the shaft and it was trembling when tis happen.

I let it cool down a bit and pull out the filament and measure the tip at end of filament.

The measure was 2,2mm so the reason is in the heatbreak 2mm/2,2mm shift.

I think only possibility is to buy original e3d heatbreak with straight 2mm hole.

I have now used about 2 rolls of filament to trying out everything.