Print issue - gumming up on nozzle

Ive been printing non-stop for a week or so and just started to have some print issues.

When i came home a print had failed - looked as if mid-way through the printer shifted layers over an inch. I restarted the print and came back half way through to the metal plate itself being crooked and moved off the bed a bit this time.

Both of these times the nozzle was completely gummed up with petg and it was covering most of the heat block.

I assumed that the cables (covered cable sleeve) from the heat bed or the nozzle assembly itself were hitting the prints as they were drooping, so I used some ties to lift them. Restarted the print and watched more closely. This time he nozzle gummed up fast and started dragging the prints along.

Can anyone have me trouble shoot this?

I always scrub the plate with dawn and a scrubber between prints. I have printed this particular file multiple times before and even tried another today, which also failed, so I dont think its the file. I did replace the nozzle with another prusa nozzle a few weeks ago, but ive printed a lot since then with no issues.

Could the nozzle be loose and leaking out before the tip somewhere? I can feel that the heat block is loose, but im not sure how to tighten it if that matters, because of the wires connected to it, which prevent turning it.

Im using PETG with the same settings ive printed with 100x.

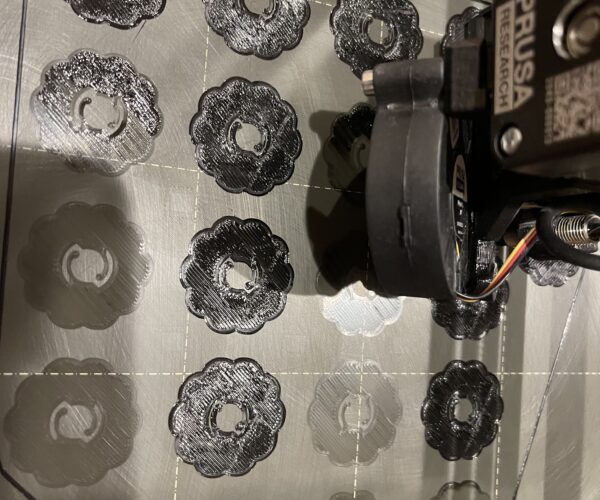

Not sure what else to add for now. Attached pics from the last failure.

Thanks!

RE:

looks like your hot end is leaking. The heat block should not be loose. I'd recommend following the nozzle change procedure, without changing the nozzle, to assemble and tighten the hot end correctly. https://help.prusa3d.com/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

Make sure everything ist clean, at the right temperature, use the correct torque and leave the right gaps...

You can use a heat gun to help cleaning the disassembled parts. Be careful when using metal brushes on the operating hot end (don't touch the wires).

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Print issue - gumming up on nozzle

The photo is a bit blurry but I agree that it looks like a filament leak.

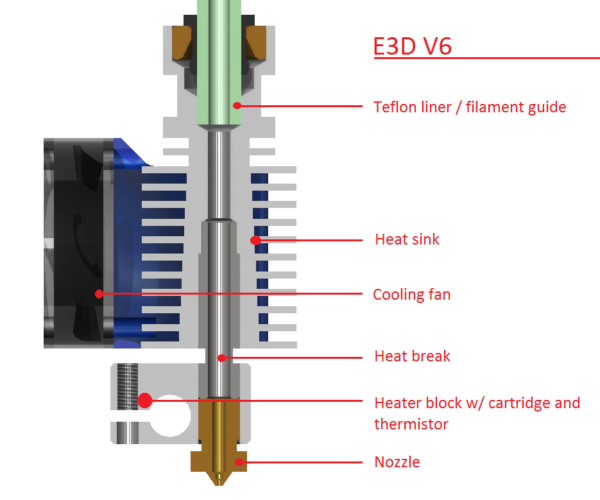

Here is the cheat-sheet diagram of how things are supposed to fit, and fit tightly. The nozzle must be snug against the bottom of the heatbreak, and there must not be any debris on the mating surfaces of those two items.

I think many users underestimate the amount of pressure that's developed as the machine forces molten filament out of the .4mm opening. If there are any leaks, as in any other way for that molten filament under pressure to get out, it will find it and leak out.

When I change a nozzle I always do a sanity-check inspection of the bottom of the heatbreak with a dental mirror, and usually do a quick chase-off of the nozzle mating surface with a file.

RE: Print issue - gumming up on nozzle

Hello,

Thank you both for the advice. I took off the fans and front of the extruder.. there was a ton of melted filament between the heat sink and the heat block, which i removed. I then tightened those two items as much as I could, cleaned, and reassembled.

The good news is that it fixed most of my problem. Im back to printing again and its doing well, but the bad news is that my nozzle is still getting covered in filament, but at a slower rate.

It no longer appears to be leaking down the heat block from the gap between the block and heat sink, which is good. It now just appears to be from t he nozzle itself. Ive tightened that nozzle as much as I can.. beyond whats reasonable I think. If its still not tight enough, im not sure what to do. Any advice on that?

Thanks

RE:

Ive tightened that nozzle as much as I can

I don't know how much that is but I can tell from experience that I definitely can tighten a nozzle tight enough to permanently damage the heat block and cause a leaking hot end. So I got myself a torque wrench (and a new heat block) some time ago and had no problems since. Well, at least no problems involving a leaking hot end...

This gets the job done by the way: https://www.printables.com/model/24539-torque-wrench-handles-from-10nm-up-to-30nm

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE:

Hmm I guess I can just order another one, but it looks like it will cost $100 after $30 shipping. Annoying since I jsut paid shipping to order something from them.

I see this on Amazon JP and it looks the same as the prusa one. Is this the same item or thats just a generic name? Looks exactly the same.

And prusa one:

https://www.prusa3d.com/product/assembled-hotend-e3d-mk3s-2/

RE:

Well, it's a clone. That does not necessarily mean it's crap but there are a lot of crappy E3D clones out there... You only know when you get them. I used a E3D clone to upgrade my A8 once, worked fine.

It will probably fit your mk3, perhaps you need to reuse your current PTFE or adjust the length of the one that comes with the clone. I'd say better a good clone than a leaking/damaged original.

Make sure you buy a 24V version, otherwise it will not last very long....

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Print issue - gumming up on nozzle

You get what you pay for!

RE: Print issue - gumming up on nozzle

Alright I ordered it. Will try to take better care of it this time.

Seems like if I just watch the torque when I replace nozzles, I should be ok in general?

Oh, I also noticed that the heatsink on the prusa store has a bag of some thermal gel with it, but didnt see that on the assembled one I ordered. Is that something i will need to apply? Its been a few years since I assembled my printer, so I dont recall if I had to do it then or not.

RE:

You need to also be sure that the mating surfaces of the heat break and nozzle are Really Most Sincerely Clean!

They must be clean and smooth enough so that the recommended torque will cause a tight metal-to-metal seal.

If there's just one crumb of scorched filament stuck in there, the surfaces will not seal and you will have a leak.

You should also run a Z calibration after changing a nozzle or doing anything that may affect the positioning of the hot end pieces.

Seems like if I just watch the torque when I replace nozzles, I should be ok in general?

RE: Print issue - gumming up on nozzle

Oh, I also noticed that the heatsink on the prusa store has a bag of some thermal gel with it, but didnt see that on the assembled one I ordered. Is that something i will need to apply? Its been a few years since I assembled my printer, so I dont recall if I had to do it then or not.

If you buy an assembled hot end (like the one you got with your printer kit in the beginning), you do not need the thermal gel. It is applied between the heat sink and the heat break (see jsw‘s pic above). So unless you remove the heat break from it’s heat sink, you do not need the thermal gel.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Print issue - gumming up on nozzle

Thanks for the advice again.

Side question - if I want to revive the assembled hotend that I replace, what parts from the assembled hotend on the site should I purchase? if its only 1 part that is most likely the culprit, then I might as well order that along with the new one. Then I can clean the old one off and reassemble.

https://www.prusa3d.com/product/assembled-hotend-e3d-mk3s-2/

This product includes:

Nozzle V6 E3D (1 pcs)

Hotend heaterblock E3D (1 pcs)

Hotend heatbreak E3D (MK3/S, MK2.5/S, MMU2S) (1 pcs)

Hotend heatsink E3D (1 pcs)Heatsink collet E3D (1 pcs)

Hotend PTFE tube (MK3S+, MMU2S) (1 pcs)

Hotend heater cartridge

E3D 24V 40W (1 pcs) with the Molex connector attached (1 pcs)

Hotend thermistor E3D (1 pcs)

Thanks

RE: Print issue - gumming up on nozzle

If you actually damaged something by over tightening the nozzle it's probably the heat block, so this is what I'd get (if you pay the same shipping it's probably a good idea to order a spare nozzle, heater and thermistor because it's always good to have spares for those).

As jsw pointed out: You might also be good when just cleaning the mating surfaces and reassemble what you got (just because I once damaged my heat block does not mean you did as well - uneven/dirty surfaces might very well be your only problem)

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Print issue - gumming up on nozzle

Thanks for the quick reply.

I went ahead and added those to the order. It’s nice that the Prusa store makes it so simple to add things to an existing order! Just open the order and click add item - with a search by name too.

I have 3 extra .4 nozzles and the one I just put on there when I caused the issue was the more expensive .4mm one that they have on the site, so I’m hoping I can still reuse that when I swap everything out.

If I remove it and scrape any filament off from near any connecting surfaces (threads or top of shaft) then I should be ok to reuse I assume.

Also, ordered an expensive fancy digital torque wrench :/

RE: Print issue - gumming up on nozzle

Also, as an update to the issue - apparently the heat block gap is still leaking. I thought that I had gotten it to just the nozzle, but now I can see where it’s coming over the sides.

Can’t decide if I should try to dismantle, clean, and reassemble it now or wait 2 weeks for the replacements. If I wait I can at least print in the meantime, albeit with some lumps in areas I have to fix. But if I could just fix it now without making things worse… hmm.

RE: Print issue - gumming up on nozzle

For the rebuild of the leaking hot end I would add a heat break to the parts list.

Cheers