Print failures after a month of success

After successfully building and calibrating my MK3, I was absolutely loving my printer. It ran almost constantly for the first month, manufacturing parts for a device I sell. Then, this past weekend during a routine print, I came in to discover the nozzle was melted into the top of the print, and even though the MK3 had declared a build complete it was only about halfway through the task. The print was still adhered to the platter.

From that point on, I have yet to get another print done or even get back to calibration. Things I've done:

- First layer calibration (several times)

- Complete re-calibration

- Cleaned both sides of the metal plate with acetone and alcohol

- Readjusted the PINDI sensor

- Changed filament

- Tried Live adjustment of the Z axis.

It was after the last live adjustment of the Z axis when I finally got a first layer to mostly adhere. I left a very small (16 minute) print working, but it only made it about halfway before part came unstuck and the filament was simply stringing all over the place.

I am at my wits end. I've been printing for years and got the Prusa because its supposed to be the best. Can anyone help me figure out why prints no longer work on this machine?

I've attached an image. The black object on the left is a print that completed last week. The silver object is the failed object, with the nozzle mark on the upper right hand side. In the background is the half-finished piece that ended up coming unstuck and strung out.

Thanks,

steve.

Re: Print failures after a month of success

If parts are coming loose mid-print, it's most likely one of two issues:

From your description, you may also be suffering from a partial nozzle clog. Try this:

If it hangs to one side or is irregular, you may have a partial clog. You can likely remedy this with a cold pull. My notes on cold pull here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Print failures after a month of success

You could also try a glue stick.

Make a big brim, with is attach to the to printed model.

Extrude filament, it should be a straight stream, if not,

do 3 or 4 time a pull out of filament, then the problem will be pull out.

Try different filament. Try different temperatures.

Slow the speed down, the infill speed of 200 or 180, i change this to 100.

You could also slow down the speed of printing, by a little only. 50 to 40 and test.

First layer, try lowering this, make it hotter, do it slower, this should be done without fan, then it should stick.

Observe if the lines are over the whole plate the same. If not the same do z calibration, if needed several times.

Also the printer needs maintenance, (search for this in manual and on the web and on youtube),

clean rods, then drop of oil on rods, every 2 weeks if you print every day.

Also check, go with z axis to the top, left and right should be at the top at the same time, if not oil could help.

Every month check the bolts, tighten all bolt, only a little bit.

Feel on the extruder, wiggle it, if to lose , tighten the bolts, i had this to loose, and there were more bolts to lose on the printer, this was after 6 months, and i did not enough maintenance.

Read forum for problems of other people, you will learn a lot.

And search on the web for this.

Re: Print failures after a month of success

Ok, so I think I've tried everything suggested. So far I've:

- replaced the nozzle (today)

- removed the heating bed and checked the underlying bolts for tightness

- cleaned and lubed all rods

- replaced the heating bed, evenly tightening all the screws

- re-adjusted the PINDA sensor

- calibrated the extruder to the heating bed

- re-ran the entire calibration wizard

- re-ran the first layer calibration

All this went fine, so I tried printing a small part with new PLA from Prusa (brass) with the heading bed set to 65C. Immediately upon putting down the first line of the first layer the filament simply glommed onto the nozzle. I stopped the print, cleaned the nozzle and tried again. using Live Z to lower the nozzle. I had to repeat this process 3 times until it would almost sort of put a line on the print bed. With the new Z adjustment (now around .900!) I reran first layer calibration. With the big Z offset the first part of calibration went ok - stuff stuck to the print bed, but the final small square just turned into a hot mess.

I'll reslice and slow things down a bit, but I don't have much hope as that doesn't seem to be the issue. No matter how well calibrated things are, the first layer just falls apart.

I'm about fed up with this thing. It worked flawlessly until one print failed halfway through. Now it's just an expensive hunk of crap. My original $300 Monoprice ran for 3 years without this much trouble. Are there any more suggestions out there? Pretty soon I'm going to have to write this off as a massive loss, write some highly critical reviews and buy something else.

Thanks,

steve.

Re: Print failures after a month of success

As already suggested, have you watched what the extruded plastic looks like straight from the nozzle? If it isn't smooth and consistent (or is "globbing" on the nozzle) then your problem is before the bed. So possibly a minor blockage. So then, have you done a "cold pull"? Sometimes even heating the nozzle up to 270-280 for a couple of minutes can help clear the crap as well.

Good luck.

Re: Print failures after a month of success

Two suggestions:

1) Raise the X-Asix enough to see the nozzle; Do a manual extrude.

-- If the filament expands AFTER leaving the nozzle your filament has moisture in it or has contaminants.

2) Wash the bed, rinse very well and handle by the edge. Dry the bed with a paper towel.

-- Install on printer, then wipe the bed with a little bit of 91% or better alcohol poured onto a paper towel. Wipe from one edge to the other, two or three passes usually is enough.

-- Now do the same wipe with fresh acetone on a paper towel. Again, one pass is usually enough.

Bad filament isn't that rare. Especially if people handle the roll touching the filament.

Re: Print failures after a month of success

Rob.16,

Yeah, I tried multiple cold pulls with both PLA and ABS. I heated it and extruded straight streams. I pulled the nozzle, soaked it in acetone and manually cleared all remnants. Finally as I mentioned earlier, I just replaced the nozzle with a brand new one from Prusa.

Tim.m30,

I've only tried one filament since replacing the nozzle, but that's not a bad idea. In the morning I'll take Rob's advice and do a cold pull, then heat the nozzle to make sure everything is out. I'll put in a filament that has worked in the past and try that. I cleaned the bed with both acetone (cold) and alcohol (91%, hot and cold) earlier today too.

Thanks for your suggestions. I'll let you know tomorrow what happens.

steve.

Re: Print failures after a month of success

There is also a new firmware, with z error fix, maybe it helps.

Check every part of your hardware if something is loose, i had the extruder loose after 3 months, check very screw/bolt if it is loose.

Check your rods for scratches on the metal.

Oil the vertical rods, above the moving part, but also on the lower part, i think the oil on top wil not flow down to the lower baring, because in the bearing is thicker grease inside.

Manual go with z axis to the top, left and right side should reach top at the same time, i often have this not good, but printer still works.

Check for dirt/plastic is not sticker in the axis/bearings etc.

Re: Print failures after a month of success

Rob.16,

Yeah, I tried multiple cold pulls with both PLA and ABS. I heated it and extruded straight streams. I pulled the nozzle, soaked it in acetone and manually cleared all remnants. Finally as I mentioned earlier, I just replaced the nozzle with a brand new one from Prusa.

In times like these I would then start from scratch and do a partial rebuild. Then do a firmware reset. In fact, reload with a recent firmware first. It can't hurt.

Happy hunting.

Re: Print failures after a month of success

Also read where doing a factory reset can clear corrupted constants that may happen over time and multiple firmware flashes.

Re: Print failures after a month of success

After turning out perfect prints for several days once again I have problem this time its a layer shift in Y

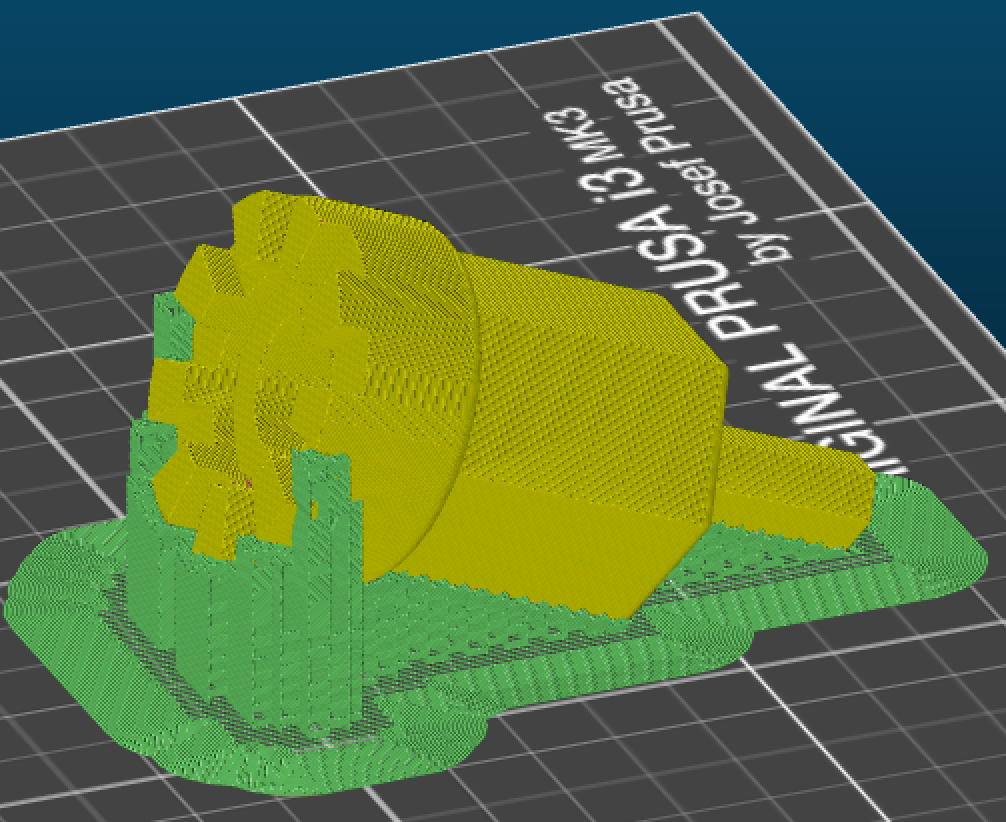

this is how it looks in Slic3r-PR

on the plus side it is a very strong scrap part and heavy pressure in a vice with a wrench did not crack it so if I get a good print It should work as intended

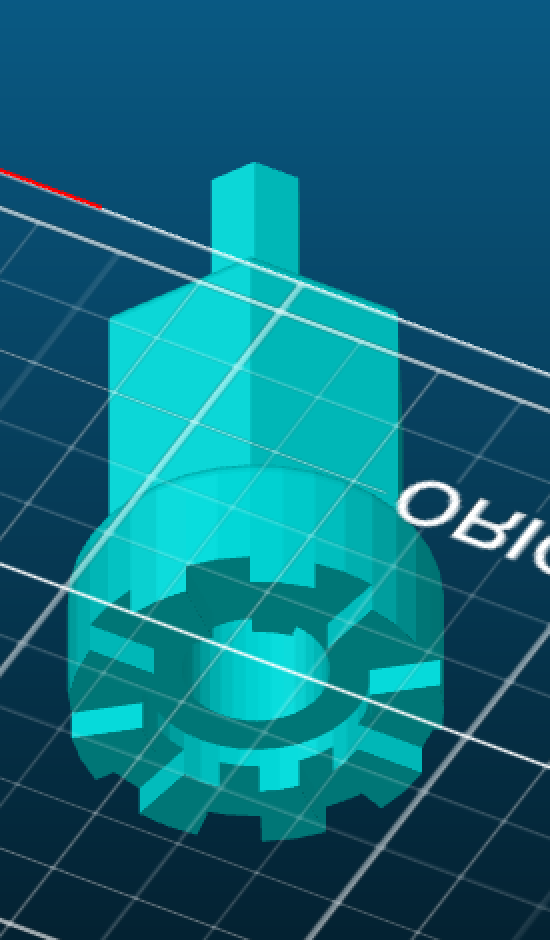

PETG with the pretty PETG settings angled like that on the build plate with supports and a 10mm brim for strength in use 50% infill 3D honeycomb 5 perimeters here it is in the slicer with out the support

the first layer shift (Y axis towards the rear of the printer can be seen, the print is at about 75% done in the snapshot above; the layer shift took place at about 60% I let the print continue in case I could do a saw and glue save for testing but shortly after the photo it did an identical shift to the rear in Yand then it knocked itself over... yes 10 mm brim and support all knocked loose right after the 2ed layer shift... the Y belt is tight and aligned as is the Y stepper drive cog... any thoughts?

Re: Print failures after a month of success

It's been a while, but I wanted to take a moment to thank all of you that took the time to post replies. In the end I think it was a combination of a number of things, including a worn nozzle and some bad filament. The final fix that seems to have gotten me back to successful printing was finding a couple of very loose screws. After a LOT of work I'm now successfully creating prototypes and production parts.

Thanks,

steve.

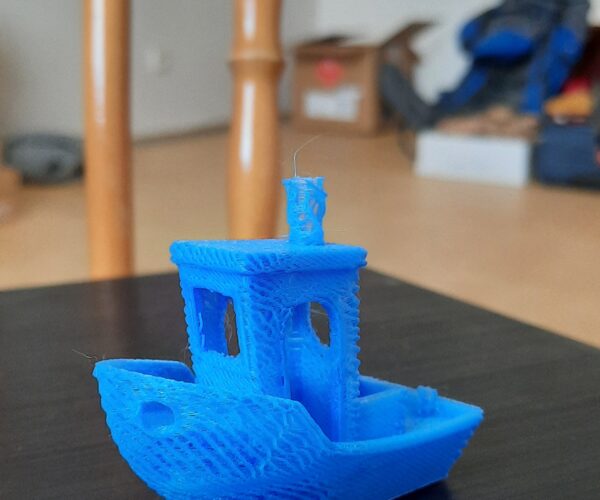

Can you help me someone? What is wrong?

You should provide some more info: what printer? how old is printer? any upgrades on printer? did you print benchy successfully before? what filament? you sliced benchy yourself? what are slicer settings? did you try to find what's wrong? what printer parts did you check? etc.

[Mini+] [MK3S+BEAR]