Re: poor print quality

Hi Timothy,

Someone said earlier in the post to remove the Spool from the top frame... i didnt notice much improve but maybe that little difference is all you need for "perfect" prints?

It doesnt hurt to try :p

Did i mentioned im printing at lower temperature?? Im in the 195-200 range.

Other than that didnt change anything.

Here is another print =)

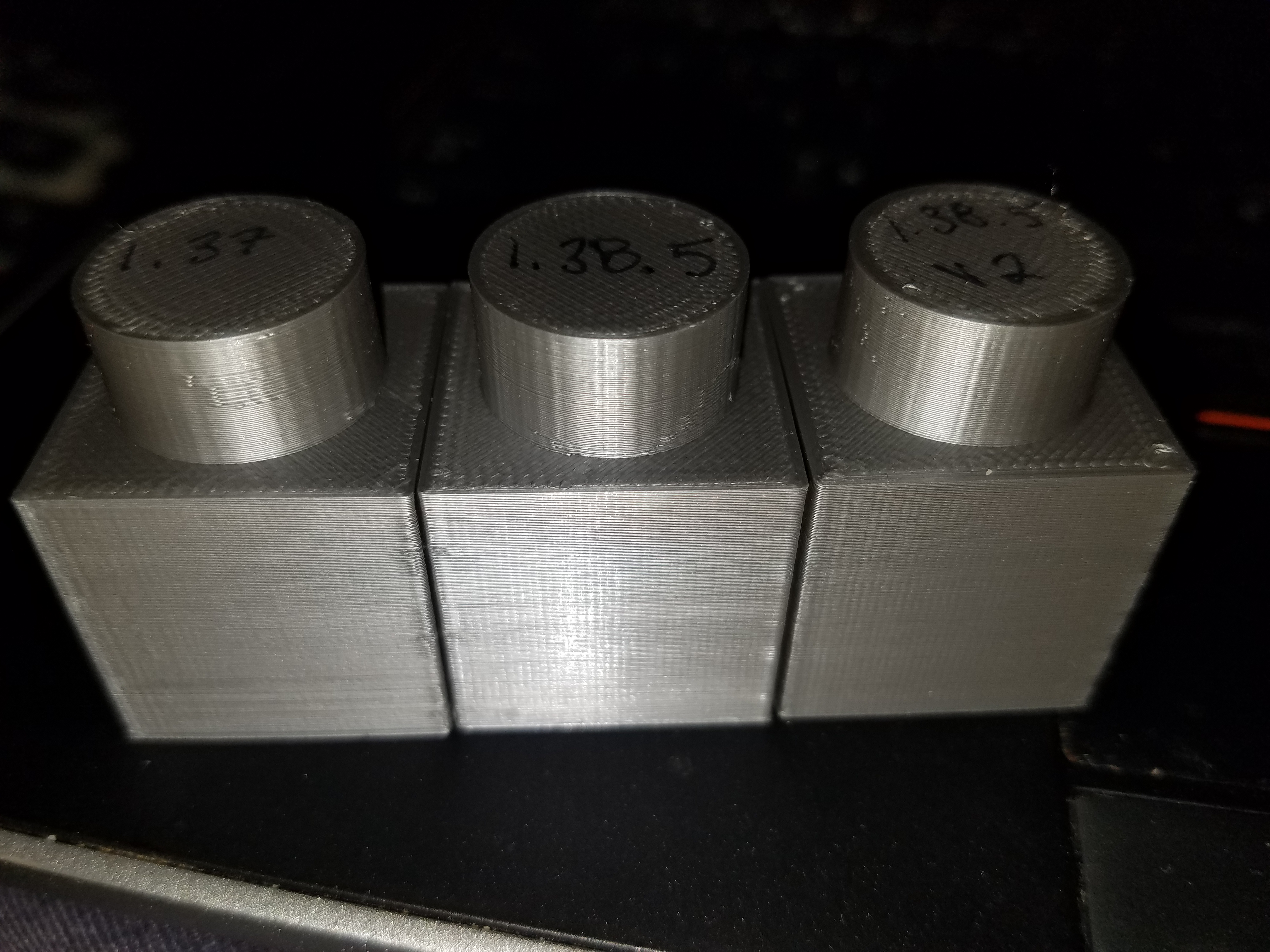

First one was slic3r 1.37 using recommended MK3 settings.

Second one was slic3r 1.38.5 using recommended MK3 settings.

Third was slic3r 1.38.5 with 30mm/s external perimeter, 3 vertical perimeter shells, 5 layers bottom, 7 top, and 205 hot end temp. Looking pretty good now.

Re: poor print quality

Hi Timothy,

Someone said earlier in the post to remove the Spool from the top frame... i didnt notice much improve but maybe that little difference is all you need for "perfect" prints?

It doesnt hurt to try :p

Did i mentioned im printing at lower temperature?? Im in the 195-200 range.

Other than that didnt change anything.

Here is another print =)

20171226_195159.jpg

First one was slic3r 1.37 using recommended MK3 settings.

Second one was slic3r 1.38.5 using recommended MK3 settings.

Third was slic3r 1.38.5 with 30mm/s external perimeter, 3 vertical perimeter shells, 5 layers bottom, 7 top, and 205 hot end temp. Looking pretty good now.

20171226_195428.jpg

Yes... its getting better.... try going to 200 first layer and 195 the rest (on hot end temperature). 😀

Re: poor print quality

"Third was slic3r 1.38.5 with 30mm/s external perimeter, 3 vertical perimeter shells, 5 layers bottom, 7 top, and 205 hot end temp. Looking pretty good now."

thanks for this help... !

my prints look much much better now.

i now use (for pla)

first layer 210°C, rest 200°C

30mm/s outer lines and 3 of them

now it looks like it should have from the start.

but still i think i will do something for better cooling.

Re: poor print quality

"Third was slic3r 1.38.5 with 30mm/s external perimeter, 3 vertical perimeter shells, 5 layers bottom, 7 top, and 205 hot end temp. Looking pretty good now."

thanks for this help... !

my prints look much much better now.

i now use (for pla)

first layer 210°C, rest 200°C

30mm/s outer lines and 3 of them

now it looks like it should have from the start.

but still i think i will do something for better cooling.

I am going to try lowering the temp even more later tonight and do the benchy that everyone seems to struggle with on the MK3. I've see the pics in another thread and it's pretty nasty looking.

I am also printing at an ambient of 15-16C. Philip and Leo, what are your ambient temperatures?

Re: poor print quality

Interesting video. How to got a better surface finish.

Bear MK3 with Bondtech extruder

Re: poor print quality

Ok so I might of found out the cause for my bad print quality. After trying everything from belt tightness to 30mms perimeters I decided that the only thing left was to try different bearings. I had noticed that when assembling they felt tighter and I just figured maybe they had smaller tolerances than the MK2. I found that trying to push the bed frame without the bed and belt attached it juddered quite a bit and sounded like it was grating rather than rolling over the rods.

I took it all apart and swapped them with some IGUS I had lying about and assembled it back up after confirming it glided smoothly over the rods. Now this time my Y belt status was at 240! and I didnt tighten it as much as I had to before so maybe the added resistance threw skewed numbers. I did a quick test print of this file https://www.thingiverse.com/thing:2542274 using the same gcode and I noticed that the weird rippling on the Y axis had gone but it was still present on the X and the circular bits weren't perfect (likely due to the same bearing issue on the X). I'm currently waiting on replacement bearings and have stripped the X axis apart only to confirm those bearings don't glide smoothly either. Once they arrive I'll update with my results

Re: poor print quality

Ok so I might of found out the cause for my bad print quality. After trying everything from belt tightness to 30mms perimeters I decided that the only thing left was to try different bearings. I had noticed that when assembling they felt tighter and I just figured maybe they had smaller tolerances than the MK2. I found that trying to push the bed frame without the bed and belt attached it juddered quite a bit and sounded like it was grating rather than rolling over the rods.

I took it all apart and swapped them with some IGUS I had lying about and assembled it back up after confirming it glided smoothly over the rods. Now this time my Y belt status was at 240! and I didnt tighten it as much as I had to before so maybe the added resistance threw skewed numbers. I did a quick test print of this file https://www.thingiverse.com/thing:2542274 using the same gcode and I noticed that the weird rippling on the Y axis had gone but it was still present on the X and the circular bits weren't perfect (likely due to the same bearing issue on the X). I'm currently waiting on replacement bearings and have stripped the X axis apart only to confirm those bearings don't glide smoothly either. Once they arrive I'll update with my results

Any before and after shots? I'm curious as to the size of the bearings, please share if you can. If the bearings are shite I'd consider purchasing and building with quality bearings from the get go.

Re: poor print quality

It would explain why my belt kept showing 280 despite it being really tight. If the bearings were binding in certain spots then giving way the motors may detect it as the belt slipping because the resistance to move the bed suddenly slips hence the high belt status indicating it is too loose, now that it can move smoothly its likely getting more accurate results which is why it suddenly changed to 240 as I tightened the belt to what I felt was right compared to my MK2 and is a lot looser than I had it before swapping the bearings out

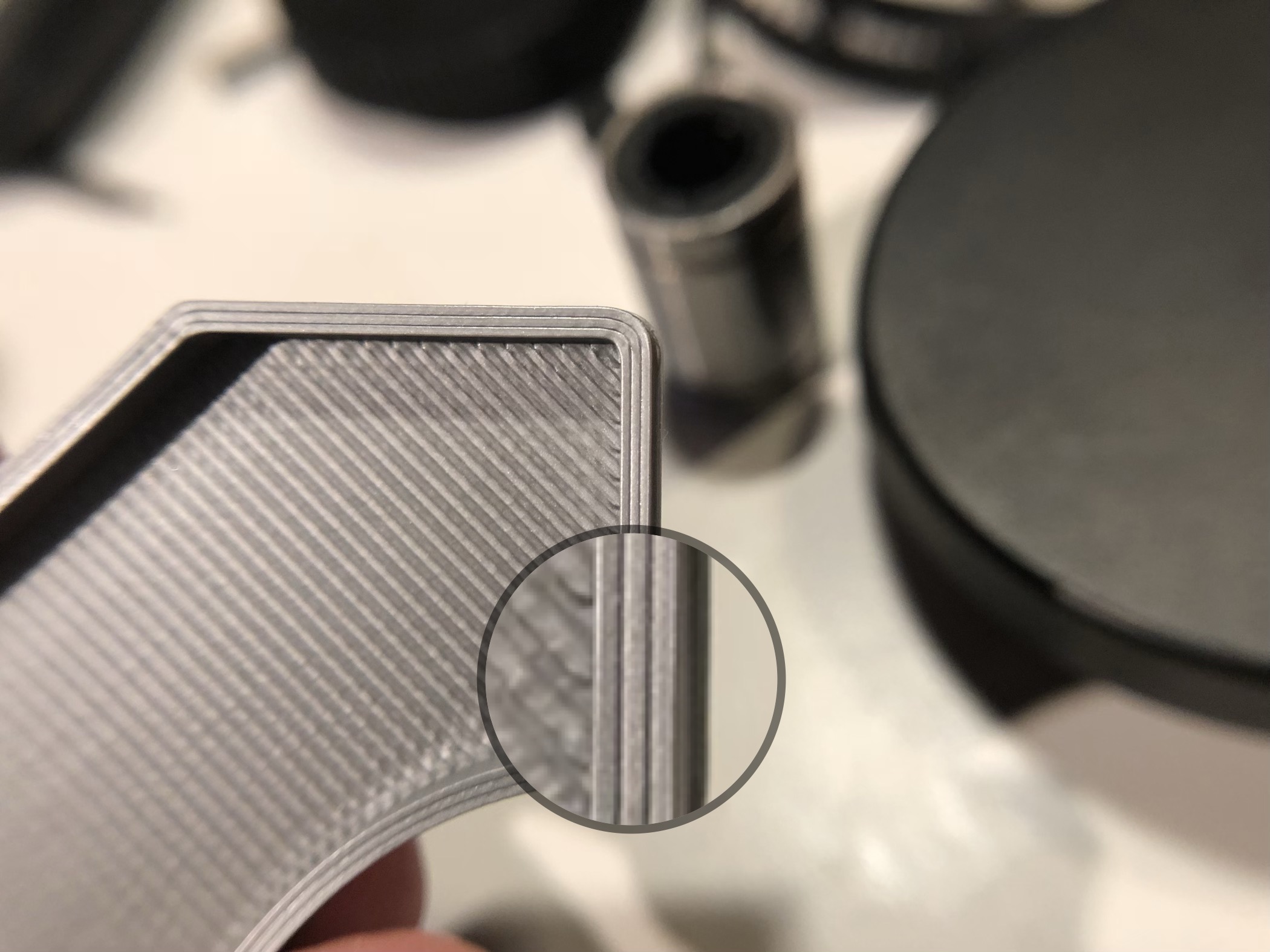

Here is the Y wall before swapping

Here it is after

Re: poor print quality

"Third was slic3r 1.38.5 with 30mm/s external perimeter, 3 vertical perimeter shells, 5 layers bottom, 7 top, and 205 hot end temp. Looking pretty good now."

thanks for this help... !

my prints look much much better now.

i now use (for pla)

first layer 210°C, rest 200°C

30mm/s outer lines and 3 of them

now it looks like it should have from the start.

but still i think i will do something for better cooling.

I am going to try lowering the temp even more later tonight and do the benchy that everyone seems to struggle with on the MK3. I've see the pics in another thread and it's pretty nasty looking.

I am also printing at an ambient of 15-16C. Philip and Leo, what are your ambient temperatures?

My ambient temperature is about 20-25C...

I've tried the benchy but the bow came out pretty nasty... and some of the sides aswell... Definitly a cooling issue...

Photo

Re: poor print quality

It would explain why my belt kept showing 280 despite it being really tight. If the bearings were binding in certain spots then giving way the motors may detect it as the belt slipping because the resistance to move the bed suddenly slips hence the high belt status indicating it is too loose, now that it can move smoothly its likely getting more accurate results which is why it suddenly changed to 240 as I tightened the belt to what I felt was right compared to my MK2 and is a lot looser than I had it before swapping the bearings out

Very interesting; my belt appears quite taut (twang sound when plucked), but still getting a 287 on the Y axis. Wonder if it'd be worth realigning the axis bearings (or swap them like you did, since the difference is quite noticeable).

Re: poor print quality

It would explain why my belt kept showing 280 despite it being really tight. If the bearings were binding in certain spots then giving way the motors may detect it as the belt slipping because the resistance to move the bed suddenly slips hence the high belt status indicating it is too loose, now that it can move smoothly its likely getting more accurate results which is why it suddenly changed to 240 as I tightened the belt to what I felt was right compared to my MK2 and is a lot looser than I had it before swapping the bearings out

Very interesting; my belt appears quite taut (twang sound when plucked), but still getting a 287 on the Y axis. Wonder if it'd be worth realigning the axis bearings (or swap them like you did, since the difference is quite noticeable).

I have some IGUS laying around.... I can test this too since i havent been able to get the Y value below 260...

But i dont really have a problem with ringing or ghosting anymore....

If you end up swapping them let us know how it turns out.

Re: poor print quality

So my MK3 was loud like a jet yesterday, so i decided to swap the Y-axis bearings with cheap chinese lm8's, its noise lowered by a big amount. so i dont get why Prusa chooses such crappy bearings?

i'll swap the ebarings on my x-axis tomorrow since it grinding also pretty bad.

i'm pretty disappointed from this Printer.

Re: poor print quality

Any good recommendations on bearings to get? Amazon links would be great :). If there are issues I really don’t want to just get more of the same as warranty. I tried rotating bearings but my y and z just sound terrible. I need to replace the X gantry pieces that hold the bearings anyway (they are loose fitting) so may as well put in good bearings.

Ron

Re: poor print quality

I am using Igus bearings on my x axis ( https://www.amazon.com/Printer-Solid-Polymer-LM8UU-Bearing/dp/B06XPRCMJS/ref=sr_1_1?ie=UTF8&qid=1514414745&sr=8-1&keywords=igus+bearings ) and they are fantastic. Just had to make sure I didn't over tighten as they dont have a metal case and can bind if too tight.

I didnt want to assemble the y axis with them since it is more difficult to change but now that i have seen them work I am going to swap when I have the time. The printer will be damn near silent once I change those out. Other than the annoying PSU clicking...

Re: poor print quality

I am using Igus bearings on my x axis ( https://www.amazon.com/Printer-Solid-Polymer-LM8UU-Bearing/dp/B06XPRCMJS/ref=sr_1_1?ie=UTF8&qid=1514414745&sr=8-1&keywords=igus+bearings ) and they are fantastic. Just had to make sure I didn't over tighten as they dont have a metal case and can bind if too tight.

I didnt want to assemble the y axis with them since it is more difficult to change but now that i have seen them work I am going to swap when I have the time. The printer will be damn near silent once I change those out. Other than the annoying PSU clicking...

I'm interested to hear if you notice any play/slop in your machine after using these bearings. From my understanding these are a bit controversial for this usage since it isn't the proper usage and they aren't compressed to achieve the proper tolerance. Still, the positive feedback from users and the appeal of no maintenance and very little sound is pretty great.

Re: poor print quality

I am using Igus bearings on my x axis ( https://www.amazon.com/Printer-Solid-Polymer-LM8UU-Bearing/dp/B06XPRCMJS/ref=sr_1_1?ie=UTF8&qid=1514414745&sr=8-1&keywords=igus+bearings ) and they are fantastic. Just had to make sure I didn't over tighten as they dont have a metal case and can bind if too tight.

I didnt want to assemble the y axis with them since it is more difficult to change but now that i have seen them work I am going to swap when I have the time. The printer will be damn near silent once I change those out. Other than the annoying PSU clicking...

I'm interested to hear if you notice any play/slop in your machine after using these bearings. From my understanding these are a bit controversial for this usage since it isn't the proper usage and they aren't compressed to achieve the proper tolerance. Still, the positive feedback from users and the appeal of no maintenance and very little sound is pretty great.

I have a few different machines and I love my Taz 6 because there is absolutely zero rail maintenance with the dry-lin bearings.

I dont feel any slop on my x-axis with the Igus installed, I was actually worried about it being too tight. I am a little worried about using the bearings with no case on the y-axis just because of the U bolts, but at least with the new frame it is a lot easier to swap than the old frame

Re: poor print quality

I need to replace the X gantry pieces that hold the bearings anyway (they are loose fitting) so may as well put in good bearings.

Ron, you are speaking about the four Z bearings here, yes - two per side?

Re: poor print quality

Yes.. the 4 bearings.

Re: poor print quality

I am using Igus bearings on my x axis ( https://www.amazon.com/Printer-Solid-Polymer-LM8UU-Bearing/dp/B06XPRCMJS/ref=sr_1_1?ie=UTF8&qid=1514414745&sr=8-1&keywords=igus+bearings ) and they are fantastic. Just had to make sure I didn't over tighten as they dont have a metal case and can bind if too tight.

I didnt want to assemble the y axis with them since it is more difficult to change but now that i have seen them work I am going to swap when I have the time. The printer will be damn near silent once I change those out. Other than the annoying PSU clicking...

I'm interested to hear if you notice any play/slop in your machine after using these bearings. From my understanding these are a bit controversial for this usage since it isn't the proper usage and they aren't compressed to achieve the proper tolerance. Still, the positive feedback from users and the appeal of no maintenance and very little sound is pretty great.

If i'm not mistaken IGUS has ones that have a metal sheet around them but the inside is just like a regular IGUS, that would help with that problem!

Re: poor print quality

.......

I'm interested to hear if you notice any play/slop in your machine after using these bearings. From my understanding these are a bit controversial for this usage since it isn't the proper usage and they aren't compressed to achieve the proper tolerance. Still, the positive feedback from users and the appeal of no maintenance and very little sound is pretty great.

I'm confused about whether or not the igus bearings are acceptable, this page https://www.igus.com/wpck/17727/products_for_3DPrinter seems to imply they are. I was also looking and like the idea of these https://www.thingiverse.com/thing:1819779 bearing straps but have to think if they were better than the U-Bolts Prusa would have adopted them by now... But in my mind the strap looks to be a better solution than the U-Bolt...