Re: poor print quality

I'm fed up with Prusa, pushing Beta product for 1000 EUR and hopping paid shills on youtube will say its a great printer worth every penny but its not, print quality is a downgrade from MK2S.

I think Josef Prusa got detached from reality

Re: poor print quality

PROGRESS!!!

This is belt/smooth idler related. Saw someone with a similar issue ( https://www.duet3d.com/forum/thread.php?pid=30141#p30141 ) who was able to fix this problem by putting a twist in their belt so the smooth side of the belt was on the idler. I tried this and got the following results, both cubes done with the same settings (.2 layers, 45mm/s ext perimeters):

Thus far this is the only modification I have made that caused an effect. I believe the ripples that are left behind now are legitimate ringing/ghosting caused by jerk/accel settings. To highlight this on the right hand photo, I took the photo so the reflection was on the smooth spot that is NOT there on the left hand photo. The left hand photo lines are consistent in that area.

That said, I am about to try to find a suitable GT2 tooth'd idler to print. Also from that topic was the following:

With the gates curvilinear profile (GT, GT2, GT3, etc), it's acceptable to run the teeth side against a smooth idler if it has a diameter equal to or greater than the effective diameter of a 40 tooth pulley of the same tooth pitch.

With 2 mm pitch belt, this equates to a smooth pulley with about 26 mm diameter.

Can anyone in the know say if the idler on the MK3 fits this spec? Doh I am stupid, that cube is 20mm, so of course it doesn't fit that spec! Also is anyone else willing to give this twist a or tooth'd idler idea a shot? 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: poor print quality

PROGRESS!!!

This is belt/smooth idler related. Saw someone with a similar issue ( https://www.duet3d.com/forum/thread.php?pid=30141#p30141 ) who was able to fix this problem by putting a twist in their belt so the smooth side of the belt was on the idler. I tried this and got the following results, both cubes done with the same settings (.2 layers, 45mm/s ext perimeters):

Thus far this is the only modification I have made that caused an effect. I believe the ripples that are left behind now are legitimate ringing/ghosting caused by jerk/accel settings. To highlight this on the right hand photo, I took the photo so the reflection was on the smooth spot that is NOT there on the left hand photo. The left hand photo lines are consistent in that area.

That said, I am about to try to find a suitable GT2 tooth'd idler to print. Also from that topic was the following:

With the gates curvilinear profile (GT, GT2, GT3, etc), it's acceptable to run the teeth side against a smooth idler if it has a diameter equal to or greater than the effective diameter of a 40 tooth pulley of the same tooth pitch.

With 2 mm pitch belt, this equates to a smooth pulley with about 26 mm diameter.

Can anyone in the know say if the idler on the MK3 fits this spec? Doh I am stupid, that cube is 20mm, so of course it doesn't fit that spec! Also is anyone else willing to give this twist a or tooth'd idler idea a shot? 🙂

I had same idea for 16T pulley on the right X carige, already ordered few different pulleys as dont have any.

The fact that the X pulley carig has design flow (M3 is off center cuz of hole diameter) won't help with the vertical lines.

Besides that, bigger pulley 20/26 would be better for print quality anyway, sure they are bigger but they will fit, same for Y axis.

I will probably do it but I expect better design und quality for a 1000 EUR 3D Printer, it is unacceptable.

I'll post photos of a print with twisted X belt later today

Re: poor print quality

here few tests with PLA and PETG and X belt twist, not much improvement.

Re: poor print quality

Hi all,

first of all, I have to say I am new to 3D printing. For me, the Prusa MK3 already delivers great quality. Nevertheless, as I am also experiencing some ghosting problems, I started to make some tests myself (beside reading forum posts).

I am not sure how to interpret my findings correctly, therefore, I just like to present what I have done - perhaps somebody can interpret it...

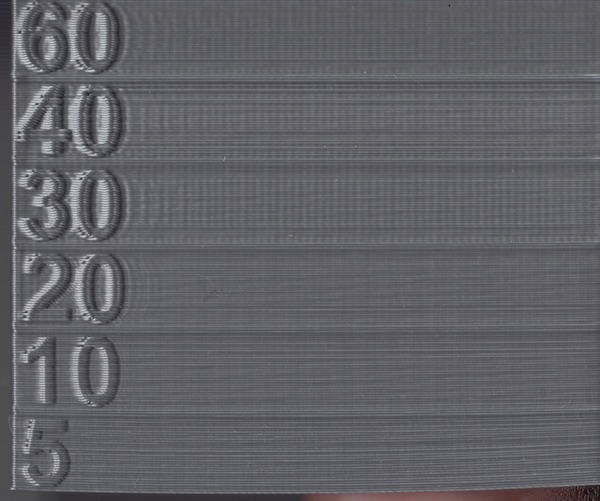

As there are some posts stating that the ghosting gets less with lower printing speed, I created some g-code which changes the speed with z-position. Here you can see an image of such a test object:

On the left, you can see the speed in mm/sec the layers are printed, each section is 7 mm high. It was done by slicing the same file several times and combining the g-codes. As you can see, the ringing is present in every part, however, it gets more prominent starting at approx. 30 mm/sec.

There were some posts stating that it could be related to vibrations. However, in my opinion, if it would be related to vibrations, the pattern should be spaced differently for different speeds. As you can clearly see, the ghosting pattern distance is the same for every speed. To check for the distance, I put the printed object on the scanner and scanned the surface:

A linescan along the y-direction of the image (in coordinates of the Prusa that equals to z), after a calibration of the image, the distance of the layers is 0.2 mm (as printed...). Now, I have done a linescan along x, where you can see the ghosting. This results in the following linescan:

By measuring the distance, the pattern distance is approx. 0.64 mm. This doesn't match the GT2 belt distance, so it is not very likely to have something to do with the belt itself. However, taking the pulley (16 teeth GT2) which has a diameter of 10.2 mm (as datasheets in the net state...), you get a circumference of 64.08 mm (=10.2 * Pi * 2). With a resolution of the stepper of 200 steps per revolution, one step should be equal to 64.08 mm / 200 = 0.32 mm (!!!). This is half the size of the ghosting pattern... while the ghosting pattern was measured from maximum to maximum in the linescan, i. e. the distance between a maximum and a minimum equals 0.32 mm.

So that's what I have done - what are the interpretations? Is it possible that the stepper (somehow) turns unevenly? That every second step is held longer (in time) so there can be extruded more filament? Can it be driver related and thus be fixed by firmware?

Would be great to hear your thoughts...

Thank you very much, best

Christian

Re: poor print quality

Hi all,

first of all, I have to say I am new to 3D printing. For me, the Prusa MK3 already delivers great quality. Nevertheless, as I am also experiencing some ghosting problems, I started to make some tests myself (beside reading forum posts).

I am not sure how to interpret my findings correctly, therefore, I just like to present what I have done - perhaps somebody can interpret it...

As there are some posts stating that the ghosting gets less with lower printing speed, I created some g-code which changes the speed with z-position. Here you can see an image of such a test object:

IMG_0474.jpg

On the left, you can see the speed in mm/sec the layers are printed, each section is 7 mm high. It was done by slicing the same file several times and combining the g-codes. As you can see, the ringing is present in every part, however, it gets more prominent starting at approx. 30 mm/sec.

There were some posts stating that it could be related to vibrations. However, in my opinion, if it would be related to vibrations, the pattern should be spaced differently for different speeds. As you can clearly see, the ghosting pattern distance is the same for every speed. To check for the distance, I put the printed object on the scanner and scanned the surface:

scan.jpg

A linescan along the y-direction of the image (in coordinates of the Prusa that equals to z), after a calibration of the image, the distance of the layers is 0.2 mm (as printed...). Now, I have done a linescan along x, where you can see the ghosting. This results in the following linescan:

Pattern.png

By measuring the distance, the pattern distance is approx. 0.64 mm. This doesn't match the GT2 belt distance, so it is not very likely to have something to do with the belt itself. However, taking the pulley (16 teeth GT2) which has a diameter of 10.2 mm (as datasheets in the net state...), you get a circumference of 64.08 mm (=10.2 * Pi * 2). With a resolution of the stepper of 200 steps per revolution, one step should be equal to 64.08 mm / 200 = 0.32 mm (!!!). This is half the size of the ghosting pattern... while the ghosting pattern was measured from maximum to maximum in the linescan, i. e. the distance between a maximum and a minimum equals 0.32 mm.

So that's what I have done - what are the interpretations? Is it possible that the stepper (somehow) turns unevenly? That every second step is held longer (in time) so there can be extruded more filament? Can it be driver related and thus be fixed by firmware?

Would be great to hear your thoughts...

Thank you very much, best

Christian

First off, AWESOME investigative work!

I was wondering about the teeth as well, is it possible that maybe too high belt tension is causing variation in tension depending on if a tooth is beginning to "dig in" along the path of the belt? Is it possible that this is happening in such a way it is doing it twice?

I am going to try running my belt quite a bit more loose than it is now, will post back in a few minutes. I am wondering if a higher than usual tension is causing the teeth to play into tension when they shouldn't be. Still trying a test print at low tension because I hadn't thought to before, but I believe you are on the right path with this being a stepper/firmware issue. Will post results as I have them.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: poor print quality

...

By measuring the distance, the pattern distance is approx. 0.64 mm. This doesn't match the GT2 belt distance, so it is not very likely to have something to do with the belt itself. However, taking the pulley (16 teeth GT2) which has a diameter of 10.2 mm (as datasheets in the net state...), you get a circumference of 64.08 mm (=10.2 * Pi * 2). With a resolution of the stepper of 200 steps per revolution, one step should be equal to 64.08 mm / 200 = 0.32 mm (!!!). This is half the size of the ghosting pattern... while the ghosting pattern was measured from maximum to maximum in the linescan, i. e. the distance between a maximum and a minimum equals 0.32 mm.

So that's what I have done - what are the interpretations? Is it possible that the stepper (somehow) turns unevenly? That every second step is held longer (in time) so there can be extruded more filament? Can it be driver related and thus be fixed by firmware?

Would be great to hear your thoughts...

Thank you very much, best

Christian

Great Investigation !!

However circumference = Pi * D

Re: poor print quality

Guys I just got some pretty neat results by loosening the belt. I took pics of yesterday's cube and today's cube together, yesterday on top, today's on bottom. Two pics with glare in different spots so you can see more surface:

These are the same gcode, same exact settings except the bottom cube has been printed with a much looser belt, loose to the point I thought it might slip if I went any less. The artifact is still there, but it's definitely wider.

Could it be this is just the belt vibrating at a certain frequency and we are seeing it in the print? Loosening it would lower the frequency and thus spread the artifact further apart?

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: poor print quality

Sure be nice if Prusa himself would chime in and give some answers instead of us all just speculating constantly. Or an eta of a fix or basically anything from those guys.

Re: poor print quality

Hey,

thanks for your comment - you are absolutely right, I exchanged diameter with radius in my head, so Pi*D is correct... however, it leads to 0.16 mm (instead of 0.32 mm), so I just wanted to say that the numbers are somehow related and it _could_ be an issue with the stepper... however, as I don't know exactly how it is programmed, it is hard to say if there could be a programming issue...

Thanks for the correction,

Christian

Re: poor print quality

Hey,

thanks for your comment - you are absolutely right, I exchanged diameter with radius in my head, so Pi*D is correct... however, it leads to 0.16 mm (instead of 0.32 mm), so I just wanted to say that the numbers are somehow related and it _could_ be an issue with the stepper... however, as I don't know exactly how it is programmed, it is hard to say if there could be a programming issue...

Thanks for the correction,

Christian

great work!

Simpler to consider the belt drive pitch as 2mm and the teeth 16 per rotation. 2*16/200 steps = 0.16mm / step ( no Pi involved)

the pattern you noticed is 0.64mm == .16mm X 4

I agree this is evidence leaning toward the stepper motor characteristics. I don't know the _exact_ character of the motor but maybe there is a pattern of ripple 4X the nominal step space?

If you assume the stepper motor and drive are set up correctly (if) then you would next look at friction in the system. Friction limits the ability of the motor to place the load where it 'wants' to. The linear bearings have seals on them that drag. I've thought that removing the seals from the bearings could be a good experiment but this could lead to damaged bearings after they ingest too much dust and belt debris.

Re: poor print quality

Just want to add that changing the smooth idler for a toothed one (GT2 20T) made zero difference.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: poor print quality

Just want to add that changing the smooth idler for a toothed one (GT2 20T) made zero difference.

That's really disappointing. I've been following the thread, having the same problem of course, and thought that might fix it. I ordered some that I'm supposed to get tomorrow. Guess they'll just go in the spare parts bin.

Re: poor print quality

Just want to add that changing the smooth idler for a toothed one (GT2 20T) made zero difference.

I can confirm this also. I installed a GT2 20T the other day when swapping out my soft rods for the harder ones sent from Prusa. I see no improvement after the installation either.

Otherwise, I do not have much to add beyond you guys great work here. I am following it intently...

Re: poor print quality

So I have replaced X&Y bearings with Igus, made a marginal quality improvement but nothing crazy. I then went to Misumi bearings... same thing just slightly louder than Igus. So far the only thing I have found that works is running the printer in stealth mode gets rid of the ringing almost completely for me. Unfortunately this leads to occasional layer shifting and obviously disables all the features. Oh well, hoping they address the trinamic issue with firmware.

Of course tonight my PSU fuse blew so now I am dead in the water anyways. I am just hoping that when I replace the fuse there isn't a larger issue as some others have seen. 🙁

Re: poor print quality

There were some posts stating that it could be related to vibrations. However, in my opinion, if it would be related to vibrations, the pattern should be spaced differently for different speeds. As you can clearly see, the ghosting pattern distance is the same for every speed. To check for the distance, I put the printed object on the scanner and scanned the surface:

scan.jpg

A linescan along the y-direction of the image (in coordinates of the Prusa that equals to z), after a calibration of the image, the distance of the layers is 0.2 mm (as printed...). Now, I have done a linescan along x, where you can see the ghosting. This results in the following linescan:

Pattern.png

By measuring the distance, the pattern distance is approx. 0.64 mm. This doesn't match the GT2 belt distance, so it is not very likely to have something to do with the belt itself...

Simpler to consider the belt drive pitch as 2mm and the teeth 16 per rotation. 2*16/200 steps = 0.16mm / step ( no Pi involved)

The pattern you noticed is 0.64mm == .16mm X 4

I agree this is evidence leaning toward the stepper motor characteristics. I don't know the _exact_ character of the motor but maybe there is a pattern of ripple 4X the nominal step space?

So I have replaced X&Y bearings with Igus, made a marginal quality improvement but nothing crazy. I then went to Misumi bearings... same thing just slightly louder than Igus. So far the only thing I have found that works is running the printer in stealth mode gets rid of the ringing almost completely for me. Unfortunately this leads to occasional layer shifting and obviously disables all the features. Oh well, hoping they address the trinamic issue with firmware.

At this point I am willing to bet a roll of Fillamentum Rapunzel Silver, that these ghosting issues have nothing, if very little, to do with either friction, belts or pulleys. I'd also urge others not to loosen your belts too much in attempt to solve this, as the belts need a good amount of pre-load to engage the aramid fibers within.

Since the artifacts are spaced exactly 4 full steps apart, I'm thinking it has to do with the steppers and drivers themselves as each 4 full steps constitutes one full period for the stepper: https://www.trinamic.com/technology/std-technologies/microstepping/

Also, the reason, I'm theorizing, why sean.s8 is seeing a difference is because in normal mode Stallguard uses one full period (4 full steps) to check for missed steps, to avoid false detects during printing, from fx friction or pumping against a raised bit of plastic. But in Stealth mode Stallguard is turned off completely so the ghosting stops.

Check this on stallguard: https://www.trinamic.com/fileadmin/assets/Support/Appnotes/AN002-stallGuard2.pdf

What I'm suspecting, is that since Stallguard continuously calculates the resistive losses within the motor (P=2*R*I^2), if the resistance within varies from motor to motor, then the default Stallguard values in the firmware might not be fitting for each printer and it might influence its behavior?

I simply don't know enough about stepper characteristics to say exactly what's going on, but I think it's too much of a coincidence for the ghosting lines to match 4 full steps for there not to be a correlation.

Re: poor print quality

Found this on YouTube on how to reduce ringing it might be worth a try.

Note the MK3 profiles run much faster and with higher accelerations than the Mk2 and could explain some of the artifacts.

Re: poor print quality

Found this on YouTube on how to reduce ringing it might be worth a try.

Note the MK3 profiles run much faster and with higher accelerations than the Mk2 and could explain some of the artifacts.

While this may help with ringing, the problem we are experiencing is a constant vertical band happening at no matter what speed due to something happening at the stepper level.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: poor print quality

Just wanted to add that the latest Feb firmware release doesn't seem to have done anything for this issue on my front.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: poor print quality

Just wanted to add that the latest Feb firmware release doesn't seem to have done anything for this issue on my front.

Same - no impact. It did however, completely fail to address the layer shifting, so that's a... plus?