Polymaker CF PA12 Nylon Tips?

Hey fam! I'm printing on a garolite/steel plate with a hardened steel nozzle. Filament should be dry. I feel like I get different results depending on the orientation of the parts. I had a good print going with just a little lift on one side now can't get it to print that good again. Also seems like only certain areas have this (over extrusion?) problem. Does it mean I have an uneven bed? Is there a best orientation to have my parts? Can you look at my settings and see if they are okay for this material? Thanks any ideas are appreciated.

RE: Polymaker CF PA12 Nylon Tips?

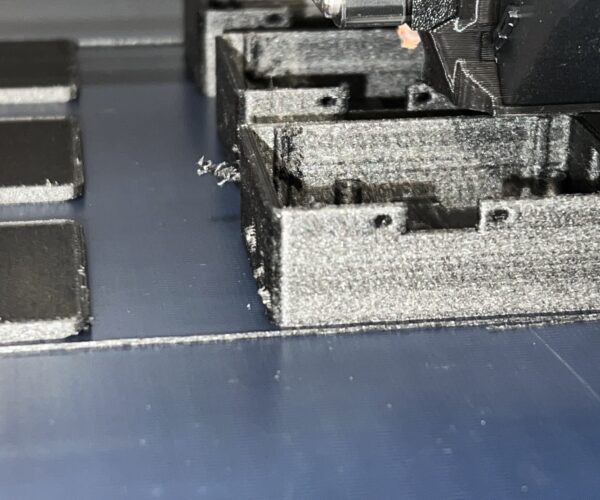

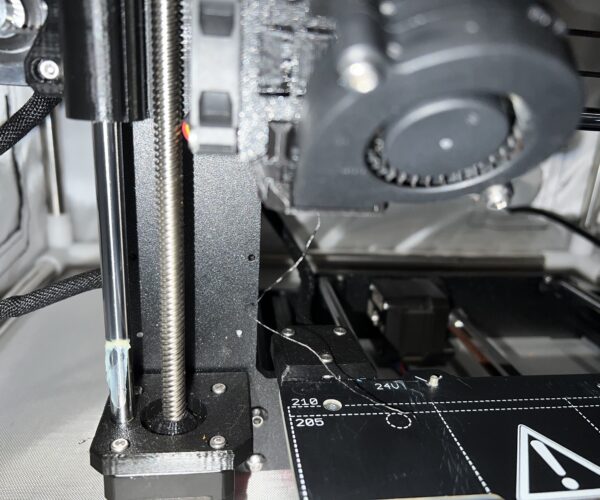

I am hearing something during the print. Maybe a scraping (Z off Set Too Low?) or bubbling (Filament not dry?). Could be contributing. Or maybe over extrusion (look how much filament pumped out after it was done). Here's a better pic of the plate.

RE:

I see that you’re using a slightly modified profile of Prusa Slicer for Fiberlogy PA CF12, as there’s no custom profile for Polymaker’s CF-PA12 in the software and you modified the original bed temperatures (105-110C) for a much lower settings of 75-65C. Polymaker recommends even lower temperatures. In fact they advise against going higher than 50C. That makes me think that Polymide PA12-CF and Fiberlogy PA12-CF15, in spite of their similar name, might be filaments with quite different specifications.

Have you tried printing with the bed at 50ºC or less ?. I assume you’re not using an adhesive on the garolite surface ?

I don’t think that the orientation on the bed has much to do with the issues because your settings show that the print fan is disabled but, on the other part, if you don’t use an enclosure maybe there’re in the room occasional draughts that might make trouble.

You said that the filament should be dry but, have you dried it or took it for granted ?.The fact that it came in a vacuum sealed bag isn’t conclusive. Those blobs in the first photo point to moist filament. You know that nylon filaments are very sensible to humidity and see that Polymaker recommends drying it for 8 hours at 100ºC

RE: Polymaker CF PA12 Nylon Tips?

There's a possibility you could be right about the "taking for granted" part. I dried it well to begin with and got a good print. Then it sat for a few hours before I started the next one. Just hard to wrap my head around moisture getting in that quick and then having THAT much impact on the print! I have it in the oven now and am not going to change any other settings. Will let you know if that fixes all the issues. I did change the bed temp for some reason. Not sure why but was originally 50 degrees. Thanks for your time on this.

Nylon MUST be bone dry at the start of the print and if it's going to take more than two or three hours you MUST print directly from a drybox. In humid weather nylon can absorb too much moisture for printing in about two hours...

Cheerio,

RE: Polymaker CF PA12 Nylon Tips?

Ya'll are completely right. Was totally the moisture. Wow! Can't believe how fast it happens.

Does anyone know if I have to treat these parts after printing?

They should be OK without post processing. The printing effects are due to water boiling off in the hotend.

Cheerio,

RE: Polymaker CF PA12 Nylon Tips?

They should be OK without post processing. The printing effects are due to water boiling off in the hotend.

Cheerio,

Sweet