PLA vendor, model or slicer issue?

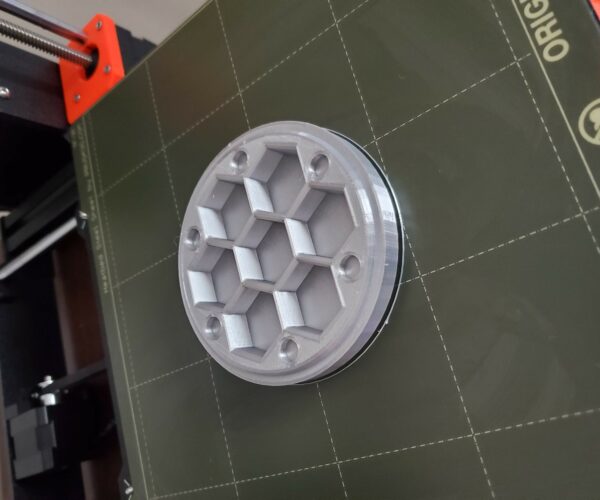

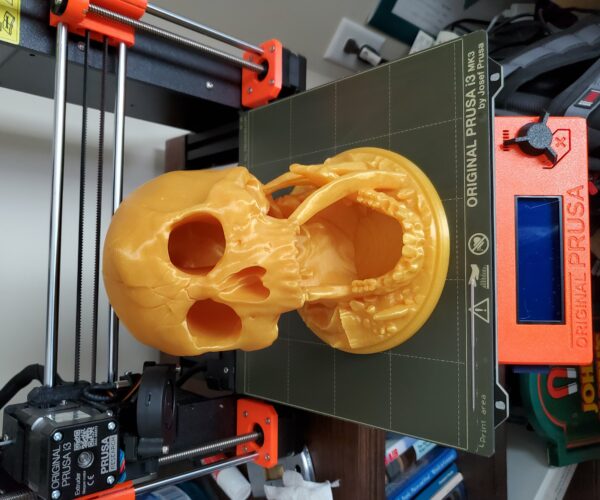

After reading many posts here & learning that the PLA has a lot to do with differences I've tried this several times. This print sticking perfectly fine. However, I haven't figured out what is going on here yet with the stringing. The "gold" version was printed on an MP mini. The silver version is on my Prusa. Please bear in mind I have many successful prints on the Prusa (thanks to a lot of advice I have found on these forums) which which includes one that took 36 hours which I've also attached for reference

.

.

RE: PLA vendor, model or slicer issue?

It's hard to guess without the 3mf file, but I'd initially guess you are printing too fast or have a clog or are under temperature for the filament, or your model is broken. I can add, a model like that should never need a brim.

RE: PLA vendor, model or slicer issue?

@tim-2

Thank you for the reply - I'll check the speed, nozzle & look at the temp settings. I've resorted to brims on models that wouldn't otherwise need them as I've had issues with lifting on edges in a few cases despite cleaning the bed & Z adjustments/calibration checks.

RE: PLA vendor, model or slicer issue?

Post your .3mf file - which is the file that you can attain by doing file/save-as in prusa slicer. That will preserve your sliced settings so we can see what's the heck going on. Without the model, and the settings - hard to say. Maybe the model is supposed to look like that ... but my guess is you're way too hot, and your bottom layer was a mess.

RE: PLA vendor, model or slicer issue?

3mf file attached.

RE: PLA vendor, model or slicer issue?

@leigh213

Um. That's going to collapse. Somebody has turned off infill.

Here's my suggestion. Set things back to default - across the board.

You still haven't told us what kind of filament you loaded.

RE: PLA vendor, model or slicer issue?

@dan-rogers

Infill -- that would explain a lot. I'm going to try your suggestion & reset everything back to default. The filament is Yousu "3D Filament", PLA, Silver, 1.75mm. Temp 190C to 225C. Platform temp 0-60c. I'm aware the first layer temp is set to 65.

RE: PLA vendor, model or slicer issue?

Turn off brim, add 15% to 20% infill. Grid will probably work, perhaps honeycomb will work better with the cup shapes. Other than that, the file doesn't explain the underextrusion. You may be fighting a clog and a cold pull or two to ensure there is nothing stuck in the nozzle may be helpful.

RE: PLA vendor, model or slicer issue?

Also turn up the heat on the nozzle, your .3mf shows your printing at 210C and the under extrusion suggests that's not hot enough try 220C.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: PLA vendor, model or slicer issue?

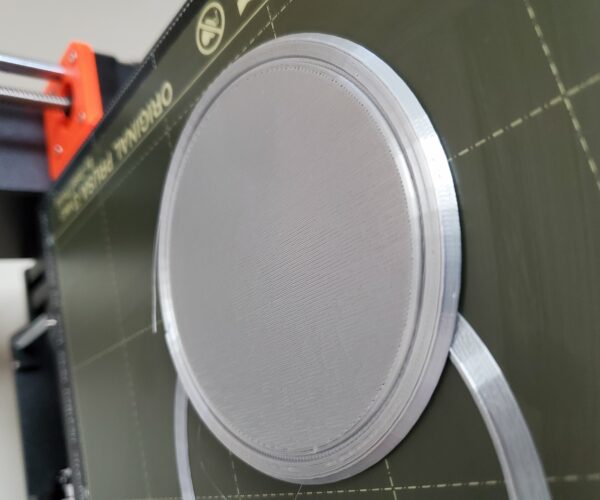

Success! Thank you everyone for your assistance. I redid the project, turned off the brim, and verified the infill. I also re-checked the first layer calibration to be on the safe side. As you can see there was zero lifting or any of the issues from earlier.

RE: PLA vendor, model or slicer issue?

You are still under extruding a bit, so look into that.

Enjoy

Swiss_Cheese

The Filament Whisperer

RE: PLA vendor, model or slicer issue?

Those silk filaments like the temperature at the high end of the range in my experience. I print them at 230 with a nozzle x so that's equivalent to 225 with a brass nozzle. Lower temps are usually a bit brittle although on your model that's probably not too much of a factor.

RE: PLA vendor, model or slicer issue?

Also - your print sheet is still very dirty. Until it is clean, expect more adhesion issues.

RE: PLA vendor, model or slicer issue?

@tim-2

Noted. Typical routine is washed & then isopropyl 91% based on comments from the forums.

@swiss_cheese

Trying hotter temps: 215 to 220 for next prints which are part of this model/same PLA.

EDIT -- the most recent pics above were @ 215. Trying 220 on next round.

@neophyl

Good to know. First few runs with this filament.

RE: PLA vendor, model or slicer issue?

@leigh213

Soap and hot water work best. Alcohol - unless you use a ounce per wipe - is wasted effort. When I use alcohol I pour a puddle onto the print sheet, a puddle 7 to 10 cm across, then using a fresh paper towel scrub until the towel is as wet as it can get then I start scrubbing with another paper towel. Using a large lintless cloth is an option others use. Once I've done the first pass, I start a second pass with a bit less alcohol.

But when I want the sheet clean, which nowadays is always - I just take the sheet to the sink and use soap and water. It is faster and more effective than alcohol.

ps: if you can see dirt or streaks or any discoloration, you already know the print sheet is very dirty. Even when you can't see any discoloration, alcohol leaves a film that will destroy a print:

RE: PLA vendor, model or slicer issue?

@tim-2

Wow ok. That does indeed look familiar with some prints & of course the streaks that were evident on my sheet. The water gets to nearly 130F here at the sink. However, I can't seem to clear marks seen in the photos from previous prints even with soap & water.

RE: PLA vendor, model or slicer issue?

@leigh213

There are times when alcohol or even acetone are useful. Some filaments leave artifacts that need alcohol to remove. But read how I use alcohol when that happens. And, I should have completed the story: after washing with alcohol, I usually take the sheet to the sink and wash it again in soap and water. As an aside, the PLA residuals rarely cause adhesion problems, they are pretty well adhered and new PLA sticks fairly well to the old residue.

Learning the rule that PLA adhesion requires a clean sheet was one of the hardest learned lessons in my 3D printing experience. The second is that fingerprints are a great way to reduce PETG adhesion (I wipe the sheet with my hands until I see copious finger prints - then squirt on some Windex to dry as a film before printing Prusament PETG).

I was close to listening to the guys that literally sand their print sheets when someone suggested washing at the sink. What did I have to lose I thought. Tried it - it worked - and I have never looked back.

RE: PLA vendor, model or slicer issue?

@leigh213

Did you fix your issue?

--------------------

Chuck H

3D Printer Review Blog

RE: PLA vendor, model or slicer issue?

@leigh213

Did you fix your issue?

Yes thanks -- the key issue was the infill being set to zero which I had not caught, yielding an unprintable model. There is still some tuning regarding extrusion as noted above, however, the print is successful now (pics in a previous reply). Also received some good feedback on how to properly clean the print sheet, which has helped with proper adhesion too.