PLA+... jamming during 0.1mm layer prints. What to do?

I've just started a print project (Curta 3:1 calculator) using PLA+ (Sunlu black) for the first time. (205-210c, bed @ 60).

It's very quickly become apparent that I cannot print at 0.1mm layers for any sustained duration, or at least, not "slowly". So far, they've happened during slow layers, e.g, top solid infill, or very tall thin parts.

Is PLA+ just more likely to clog like this? I've never really had issues with regular PLA even at low heights unless I did something derpy like leave the enclosure closed. (I completely removed the upper lack table this time to see if it helped, no luck).

Much larger parts printed at 0.2 or 0.15 have had no issues.

When it's happened, removing the filament and clipping the oversize blob at the end lets printing continue without issue so it doesn't seem like it's from junk in the nozzle or it'd still be clogged. A few times, when re-loading I will see steam coming off the purged filament that it's dropping onto the bed... I suspect it's just that what was in the hot zone too long and started to cook/degrade. The filament's in a drybox and doesn't normally steam like that when printing.

What can I do to prevent this? Lower print temp? bump speeds for slower features? It's not stupid hot here in the northeast at the moment or I'd suspect that had something to do with it.

Extra info:

- Skelestruder

- Hot-end sock

- 3.8.0

- 0.6mm retraction

- No enclosure

- Ambient temp ~60s- low 70s

- have done many, many, many prints with regular PLA without issue.

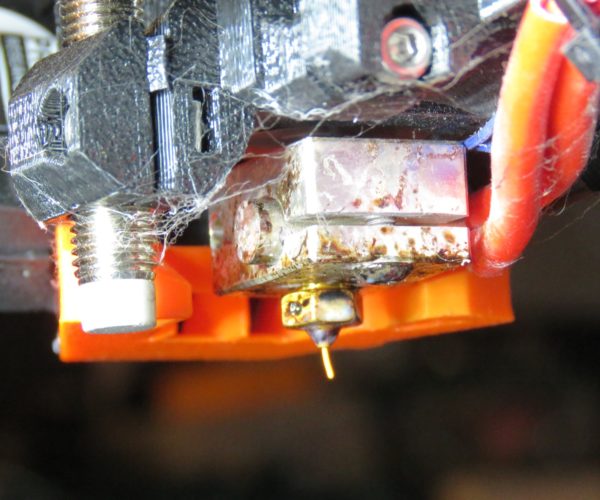

- Extruder has not been disassembled since skelestruder build, see above bullet

- Has collet clip for hot-end PTFE tube

- MMU installed, so stock E3d heatbreak not an option.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Any PLA+ that I've used (primarily eSun) has printed well, but I don't have any experience with Sunlu. Steam off the nozzle with PLA is odd though. Can you try drying the spool? If it was soaked at the factory or in shipping, it might be so saturated that the dry box is ineffective.

Have you tried bumping speeds higher to increase flow? Might be a stringy mess with thinner layers, but worth a shot.

I've had a couple of spools that are just plain crappy. One was recycled PET, and I've forgotten the other. I finally relegated them to "special use only" and used them on projects to burn through them.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PLA+... jamming during 0.1mm layer prints. What to do?

I actually had it drying not too long ago, had it at ~55c for several hours. But I just cracked open a fresh spool of sunlu white PLA+; I was planning to run some 0.1mm parts with that as well so we shall see...

It also doesn't snap/pop like wet filament does; I wonder if this isn't steam but just crap from it cooking while being jammed.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Vintage - are you using the stock heat break?

I had similar issues and replacing the heat break simplified my life. I can't explain how it was jamming at lower layer heights, but with some filaments it was impossible to print 0.05, and 0.1 was sketchy. My best guess is the nozzle/heat break position in the heater block is far more critical than anyone wants to admit. The stock E3D-V6 heat break removes that factor.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Vintage - are you using the stock heat break?

I had similar issues and replacing the heat break simplified my life. I can't explain how it was jamming at lower layer heights, but with some filaments it was impossible to print 0.05, and 0.1 was sketchy. My best guess is the nozzle/heat break position in the heater block is far more critical than anyone wants to admit. The stock E3D-V6 heat break removes that factor.

From my main post: :-/

- MMU installed, so stock E3d heatbreak not an option.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Actually, many people using the stock heat break are using it with an MMU and not having issues.

You might play with changing the nozzle/heat break interface location within the heater block. Move the heat break deeper, so the neck is flush with the block, or even a quarter turn farther in so the neck is below the surface; and if that doesn't help, try moving the neck out of the heater block, E3D images suggest 1/4 to 1/2 turn high, anyway.

Beyond heat sink paste differences, this position is the only variable I can think of. My recollection is poor, but I think my jams started sometime after replacing my nozzle the first time (trying to print glow filament), and never went away even with multiple changes afterward. I tried to follow the Prusa instructions that first time and may have messed up the default assembly positions.

My theory here is that moving the step lower gets in into the melt zone. Math I've done says it isn't possible, but perhaps getting a little closer is enough.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Pretty sure mine is too, but I can't see because of the hot-end sock (and I don't currently fancy taking it off - it's in good shape but been on there long enough that it's probably stuck and would tear...).

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Well, you don't need to have it at temp, just sufficiently hotter than the transition temp where the PLA softens enough it can be forced past the step by the extruder.

I found a "min print speed" in the filament settings, I bumped that up so we shall see what happens.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

I'm going to follow this thread because I'm having some issues with eSun PLA+ and would like a solution. I can print PLA without jamming but when I try the PLA+ I just bought, it starts to jam. Interested in seeing any settings that may help this issue.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

FWIW I did do a 0.1 print with white PLA+ without issue after having upped the filament "min print speed" setting to 30 (from 15). Could probably go lower but 35 works fine for me as my skelestruder is lighter than stock and so ringing is at an acceptable level. I have not yet tried to reprint using the black that was giving me issues before.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

@vintagepc

First I'd like to say that I officially hate Sunlu PLA+. I cannot get small features (such as supports) to stick well to the PEI bed not matter what I try (some colors are worse than others). Larger contiguous bottom layer prints are sill ok. However, having said that, I haven't seen any issues with printing with it after the first layer. I've mostly done 0.2mm prints with it, but I have done one 0.05mm layer print and it worked fine. I typically print it at 220 to 225C, which is a bit higher than you're doing.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Interesting, though if I was printing too cold, I'd expect that faster speeds, not slower ones, would have triggered the issue. I haven't had any issues with my prints so far in the adhesion realm.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

If ringing is an issue, you might try reducing the jerk setting. That initial kick can rattle things pretty good at higher print speeds.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

Interesting, though if I was printing too cold, I'd expect that faster speeds, not slower ones, would have triggered the issue. I haven't had any issues with my prints so far in the adhesion realm.

Actually, if I understand the issue correctly (which I may very well not), what happens is that the regions in the heatbreak where the filament solidifies gets closer to the heater at lower temperatures. Therefore, when printing slower, there may be more time for the retracted filament to become solid (and get stuck at teh 0.22 to 0.2mm transition), whereas at faster speed the filament may not have time to do that. At higher print temperature, the point of solidification is higher up the heatbreak, so is in a "safer" zone. That's why there have been reports that printing at higher temperature leads to less jamming.

Also, for my hotend, I added some thermal heatsink compound on the heatbreak threads on the heater side and haven't had a jam since then.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

As mdan says, it is open as to why this heat break jam happens to some but not all MK3 users. I recently recalled that my jams started after I had printed a small bit of glow filament, about 400 grams total. The heat break is polished in the lower regions to help warm sticky PLA slide, and I wonder if in my case the glow roughed up the heat break to a point it started sticking too much and allowing retractions to build a plug. All hypothetical guesswork, but prior to glow the printer worked, after glow the print failed like clock work. New E3d heat break fixed it and I moved on... but now I wonder.

Measurements I've done hint the heat break is below 60c at the top of the neck, making the thermal gradient pretty steep. Math says the step is below a PLA melt point, but within what we'd consider the glass temp. But my measurements were not made with a IR camera and are subject to some error. In all the cases I had, the jamming was unaffected by print temperatures. And cases I've talked others through, the same: increased print temps didn't help.

I've added the abrasive question to my list of things to ask next time I read someone has printed for a while but now all of a sudden they are having lower heat break jams.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

As mdan says, it is open as to why this heat break jam happens to some but not all MK3 users. I recently recalled that my jams started after I had printed a small bit of glow filament, about 400 grams total. The heat break is polished in the lower regions to help warm sticky PLA slide, and I wonder if in my case the glow roughed up the heat break to a point it started sticking too much and allowing retractions to build a plug. All hypothetical guesswork, but prior to glow the printer worked, after glow the print failed like clock work. New E3d heat break fixed it and I moved on... but now I wonder.

Measurements I've done hint the heat break is below 60c at the top of the neck, making the thermal gradient pretty steep. Math says the step is below a PLA melt point, but within what we'd consider the glass temp. But my measurements were not made with a IR camera and are subject to some error. In all the cases I had, the jamming was unaffected by print temperatures. And cases I've talked others through, the same: increased print temps didn't help.

I've added the abrasive question to my list of things to ask next time I read someone has printed for a while but now all of a sudden they are having lower heat break jams.

No abrasives in my case; the one roll I own is a sample pack and it's safely sealed up.

RE: PLA+... jamming during 0.1mm layer prints. What to do?

I have had exactly the same issue with Sunlu PLA+ - I just avoid it now.

Know it precisely to the be filament as did extensive testing (ie sunlu - jam, swap filament to another and fine, swap back - jam) - I also tried brand new and three reels. Something too cheap in their production, so have given up!