Perfect 0.4mm Nozzle Prints, Failing 0.6mm Nozzle Prints

Hello All!

I've had my Prusa MK3S for about a week, and a CR10 before that. I have about two years of 3d printing experience. All week long I have been making great PLA 0.4mm/0.2mm height nozzle prints, using PrusaSlicer defaults (with some minor changes like additional brim for models with sharp corners, etc.)

This morning I decided to swap out the 0.4mm nozzle for a 0.6mm nozzle... and have yet to make a good print.

My PrusaSlicer settings are the default preset "0.40mm DRAFT 0.6mm nozzle MK3"

MY setting overrides are: increased layer height to .48mm, add model brim to 10mm, changed infill to Grid. All others are default.

It does the first layer very well, and the outline at 35-45mm/s just fine as well. The problem arises when it gets to 70mm/s for the horizontal shells, on outer edges of the 'longer' runs of plastic.

I'm using HatchBox PLA at 210 degrees.

Things I've tried:

Adjusting Live-Z to extremes, and everything in between on the second layer, no change (does get worse at high/low extremes)

Adjusting temperature to as high as 250 degrees, no change.

Tightening bondtech idler pulley screw a LOT, to the point of crushing the filamant, and also backing it off so much it started slipping (clicking noises).. no change

Disassembled extruder to ensure there was no binding in PTFE tube.. filament makes it through to heater block/nozzle with VERY little resistance.. replaced PTFE anyway, made sure collet was pulled out while PTFE tube was pushed in.. no movement of tube at all.. no change.

Please see the below picture:

It really has been printing beautifully with 0.4mm nozzle, but was aiming for quantity in place of quality for this handful of print jobs. Any thoughts on why the above is happening would be appreciated!

RE: Perfect 0.4mm Nozzle Prints, Failing 0.6mm Nozzle Prints

Additional info: I replaced the E3D 0.4mm nozzle with an E3D 0.6mm nozzle, bought from E3D website (when I also bought a Titan Aero extruder for CR10).

RE: Perfect 0.4mm Nozzle Prints, Failing 0.6mm Nozzle Prints

Heyrob,

have you tried using the default settings in the 0.6 profile, you may simply be overloading the heat block melt capacity...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Perfect 0.4mm Nozzle Prints, Failing 0.6mm Nozzle Prints

Thank you for the response!

I tried what you suggested, with the 'one add-10mm-of-brim change' setting change, and this is the result:

Afterwards, I replaced the 0.6mm nozzle with the 0.4mm nozzle the MK3S shipped with, selected the default MK3S 0.4mm nozzle printer profile, and used the '0.3mm DRAFT MK3' preset... sliced and printed with the below results:

The print size is 94mm x 57mm in all pictures.

In both cases you can see the quality 4-6mm from the edges start to deteriorate. Not exactly sure what is happening here. If the printer is told in the gcode to move/extrude a certain distance that goes all the way across from edge to edge in a single command, what is happening in this 4-6mm area that might change?

Any and all help is greatly appreciated!! Thank you all!

RE: Perfect 0.4mm Nozzle Prints, Failing 0.6mm Nozzle Prints

Is the firmware in the printer slowing the x/y and e motors down in those areas? If so, the extruder is being asked to move less plastic... so if anything, if it was a feed issue with the PLA, it would only improve near the edges, not worsen (if the extruder is under mechanical limits of resistance)

Unless maybe the edges ARE the 'more solid/complete' layer areas, and bulk of the center area of the layer is not as complete/flat ? That might explain what is going on in the default 0.6mm nozzle and 0.4mm nozzle prints pictures above, but not the initial photos at 0.48mm w/0.6mm nozzle, where it looks like the plastic is missing and/or being drug towards the center of the print.

(FYI, you can see the pictures in much higher detail if you r-click and open image in another tab)

I'm at a loss everyone, just can't figure this one out. Thank you all for taking the time to read over this, and any suggestions are much appreciated!

RE: Perfect 0.4mm Nozzle Prints, Failing 0.6mm Nozzle Prints

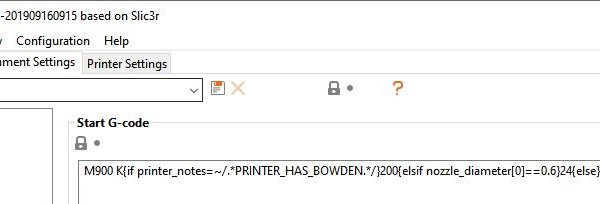

Just guessing, there is a feature called 'linear advance' which changes extrusion rate throughout the print...

it is enabled in the slicer by changing the K factor in the filament custom gcode section

if you comment that out, i believe that switches you to basic mode which may work better!

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK