Nut and bolt threads don't fit

Absolute new guy here. About 10 days with printer in hand.

Trying to learn Fusion 360,with video tutorials called Learn Fusion 360 or Die Trying - which I find very helpful. Lesson 7 you design a nut & bolt combo. Supposedly all set to print. So, I printed it. It doesn't want to thread together. Kinda sort fits together, but the threads really just bind up. I guess I would say the threading didn't work out.

Should this work?

Filatstruder Veracity PLA, printed using Prusa Slicer defaults, and Generic PLA settings.

Attached is the fusion document. Printed from Fusion's 3d print option, which invokes Prusa Slicer. Prusa Slicer to g-code -> Octoprint.

Don’t trust forum advice.

RE: Nut and bolt threads don't fit

Well, here is the fusion document and the g-code.

Don’t trust forum advice.

RE: Nut and bolt threads don't fit

I found that Fusion 360 threads work well if you select the loosest tolerance. The epiphany for me was realizing that calibrating my extrusion multiplier was absolutely essential for any sort of close tolerance fit. It makes perfect sense. If my slicer is issuing gcode that extrudes filament using settings that don't match my real-world filament, there's a chance of under or over extrusion. Usually not much, but just enough that a small amount of over-extrusion will cause problems with tight tolerances. Once I started making a point of calibrating for each brand and type of filament, I'm able to print with much tighter tolerances. Here's a 12mm nut & bolt generated in Fusion 360 with no further adjustments other than the thread settings:

The nut spins freely with a flick of the finger. I'm able to get M5 nuts & bolts to work, though of course, the bolts aren't particularly strong. Of course, big chonky threads work too:

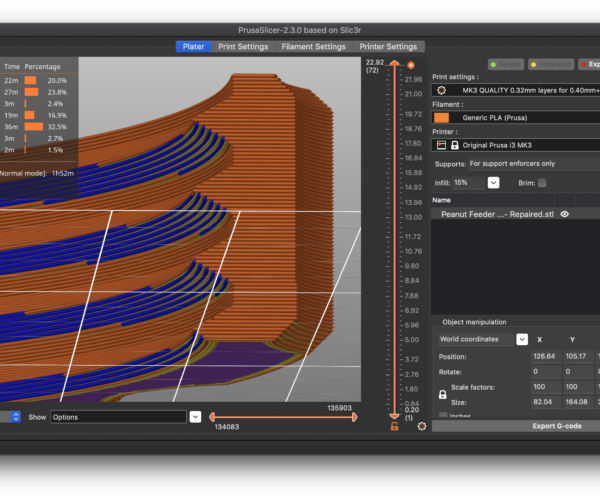

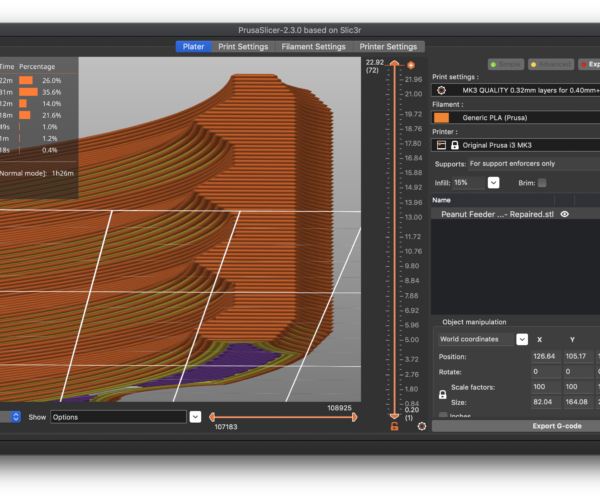

A common problem with 3D printing threads is having strands of filament pulled across the center of the print. This is often caused by poor inter-layer adhesion due to the extreme overhangs created by threads. You can view this in preview mode after slicing:

The key is to print threads with a low layer height so there is a good width-to-height ration to ensure good inter-layer adhesion. This should eliminate the overhangs:

I use modifiers to lower layer heights on threaded sections while keeping higher layer heights for vertical walls. You can see this on the center section of the bird feeder print.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Nut and bolt threads don't fit

The Fusion thread tolerance defaults are usually too tight for most Printers (but as @bobstro said you may be able to get it to work). I usually modify the threads manually. I found this video to be super helpful:

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Nut and bolt threads don't fit

@fuchsr

Thank you. I have a threaded nose cone that is off center. I will try to use the video to fix it.

--------------------

Chuck H

3D Printer Review Blog

RE: Nut and bolt threads don't fit

Thanks Bobstro and Fushr, I have just modelled my first complicated item in Fusion 360 (Why, oh why did I not use Fusion earlier, so much better than Freecad)

There are a few threaded items on it, so really good timing 😀

Tank you very much!

RE: Nut and bolt threads don't fit

@clarmrrsn

Concur. This has fixed my problem.

--------------------

Chuck H

3D Printer Review Blog

RE: Nut and bolt threads don't fit

Well, I did fuss with this a bit.

1) Extrusion multiplier. I did the precision calibration, and came up with .46 to .47 with moderately priced calipers of unknown fidelity. That was using the Veracity PLA. Printed the same with the Prusa supplied (not Prusament) PLA, and got the same #s. Whatever. Adjusted my multiplier to .97 just for giggles.

2) I was/am printing .2mm layers, so didn't have that overhang thingie going on. I did fuss with the settings to see how and when that happens. A very useful exercise. I like that.

3) Used the vid tutorial to loosen the calibration. Yet another good learning exercise for me. Good! But, while it did what it said it did, I was not that impressed with what it did. Sloppier than I liked. Maybe, maybe, with more tweaking...

Decided that the best option was to chase the threads. Spins like a politician at a fundraiser with the slightest effort. Slick.

All this was just a learning exercise, but I really appreciate such thoughtful advice from all-y'all. I am making a best effort to really figure this stuff out.

Don’t trust forum advice.

RE: Nut and bolt threads don't fit

How timely. I "hand rolled" a threaded plug (two parts, to securely fill a hole but be removable). Took a "pole end" pattern, made a negative, and then shrank the screw side by .2. That wasn't enough to create the tolerances needed - cuz I forgot that the .2 divided by 2 sides = .1 mm tolerance - too tight for a pole end screw that is for sure.

Since they were JAM tight, though, it served my purpose. I don't want the kids in the preschool to be able to unscrew them.

RE: Nut and bolt threads don't fit

I am just printing my first test M10 nut and threaded shaft at 0.1mm layer height. Have not calibrated the extrusion multiplier yet, see how it goes.

See how it comes out, I have ordered the E3D Nozzle Pro Pack today so got a better nozzle selection as well for the upcoming print, as will almost certainly need a smaller nozzle for the tiny parts.

Fingers crossed.

Tank you very much!