Nozzle clogging on flat parts (PLA)

Hello,

I have a very strange clogging issue on my Prusa i3 MK3 (with MMU2 sometime).

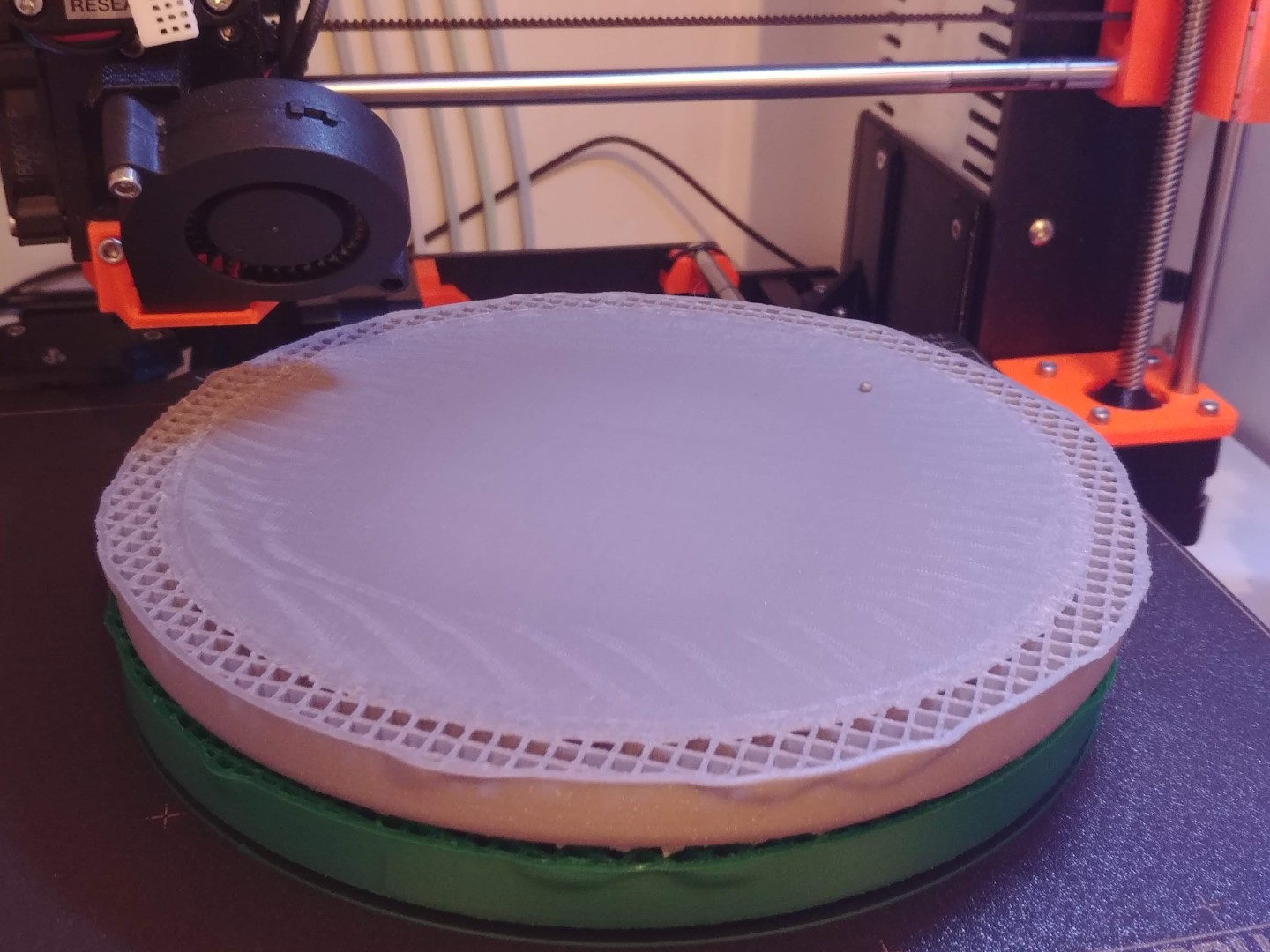

I have tried to print a model, first in Grey (Prusament) (with the MMU2 in single mode)

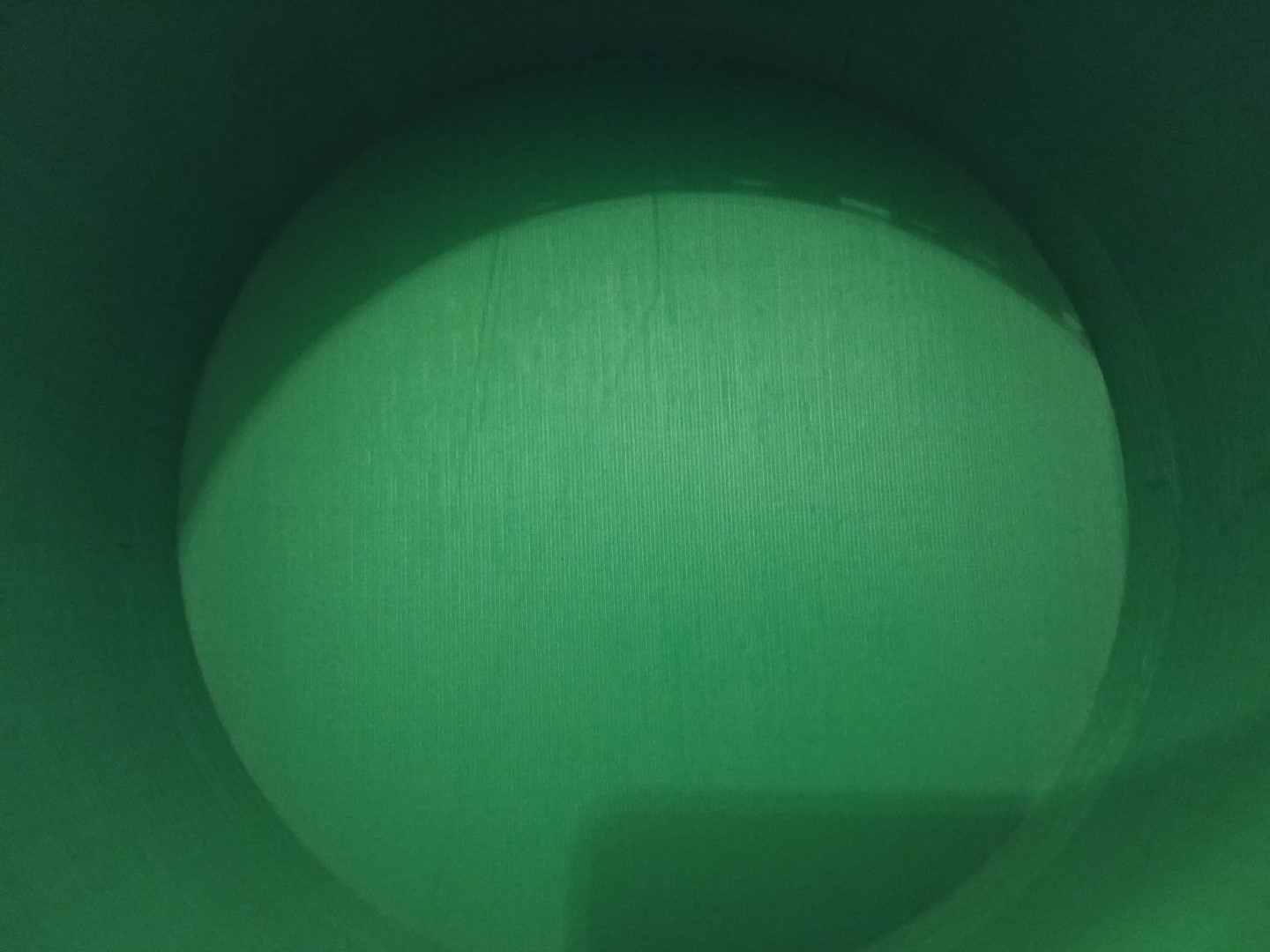

Then in green (Prusa PLA) with some success, the bottom of the pot is perfect (with MMU2 in single mode)

The i retried in Green and it failed exaclty the same way as in Grey, but this is not the same exact model in the MMU2 was unplugged (I also used PrusaControl for slicing instead of Slic3r PE)

When the print stops after the bottom of the pot it is because the nozzle is clogged. Also the 2 times I have weird waves on the surface. I beleive it has something to do with.

Does anyone have any idea of what append ? Because I really don't...

One more thing :

- Grey try : Sliced with Slic3r PE at 0.2 mm and printed at 100% on Normal mode

- Green 1st try (mostly successfull) : Sliced with Slic3r PE at 0.2 mm and printed at 50% and silent mode during the difficult part

- Green 2nd try : Sliced with PrusaConrol at 0.2 mm and printed at 60 % and Normal mode

Thank you for your help !

Re: Nozzle clogging on flat parts (PLA)

Is it clogging or something else?

By the part size, I'd expect to see some part warpage and lifting which will cause upper layers to be compressed - which may lead to clogging if the extruder can't create the pressure needed to continue extruding against the surface. You can usually hear this as the head starts banging into infill, and see 'smudging' or excess material on the perimeter.

Try increase bed temp to 70c ... that may help with any warp/lift issue.

Re: Nozzle clogging on flat parts (PLA)

Hello,

The nozzle is only clogging.

I checked, there is not warpage or lifting from the bed on my 3 tries. I cleaned the bed very carefully before each print.

You point something very interesting, on the almost good one i can clearly see an excess material on the perimeter right after the flat surface (ie, the bottom of the port 2 cm from the start of the print).

Re: Nozzle clogging on flat parts (PLA)

By part lifting, the warp is minimal, but enough the part raises a fraction of a millimeter - at 0.2 mm layer height, any lift is a problem.

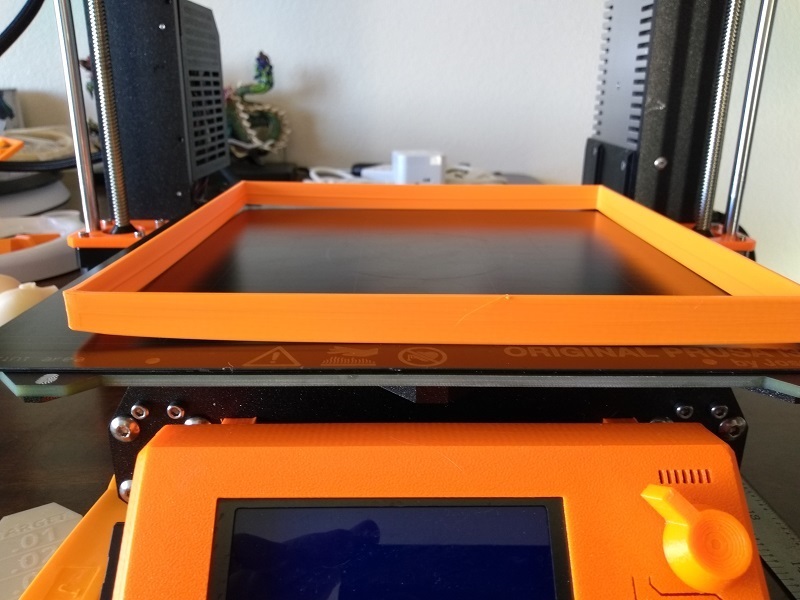

This close up shows highlighted debris that is probably caused by the nozzle scraping the part as it moves. There is more inside the perimeter that is also questionable. This is a symptom of the part lifting; and on large parts like yours, one side may lift a fraction of a millimeter and not even be visible to the eye. Increasing bed temp 5 to 10c is an easy fix.

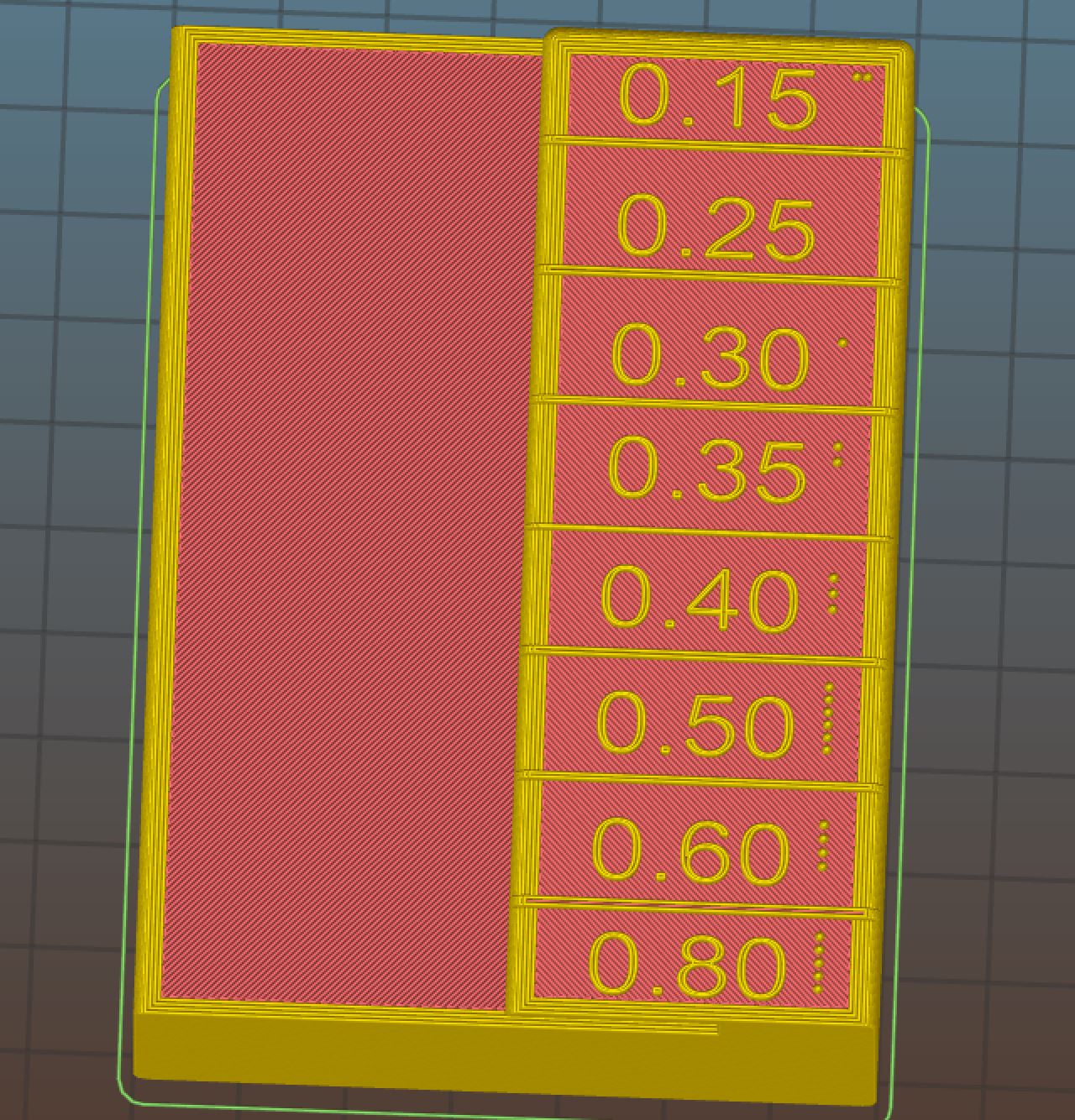

Also - on large prints, GRID infill can cause problems since the nozzle moves fast enough it hits the last infill stripe as it moves along. It lays down the X direction fine, then scrubs across those places as it lays down the Y direction (you can hear the thumping). Slowing infill to under 100mm/s is one way to compensate... I use a different infill like 10% to 15% Gyroid. Gyroid is normally slower than Grid, but faster than slowing Grid to 75mm/s.

Re: Nozzle clogging on flat parts (PLA)

You are right, the part was probably lifting, just a little...

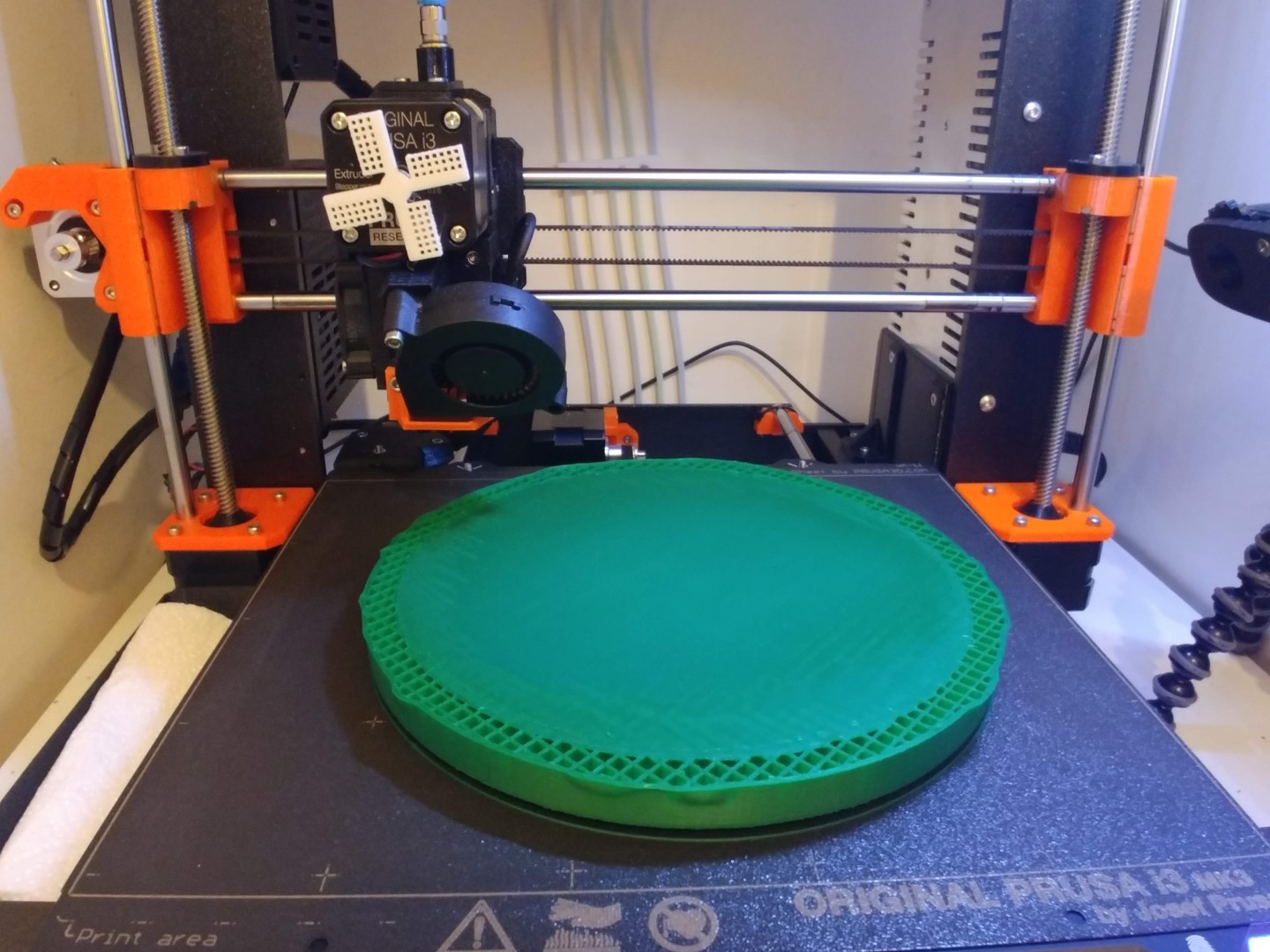

I used more glue this time and a successfully printed the full part !

Grid filling is an issue and I slowed the print speed to avoid any problems.

But I sill have some, on the exterior of the part, exactly at the height of the bottom interior :

The model STL is smooth, the slicer seems good to but the result is not as expected.

Do you have any idea of what append ?

Re: Nozzle clogging on flat parts (PLA)

That line on the outside is from the part lifting from the bed. Glue isn't a solution, but a clean bed and raising the bed temp to 70c will help. I could show you dozens of prints where this lifting has happened. Most recent was a few days ago when I forgot to raise the temp after layer 1. Anything over 10cm is suspect.

It's also common to see artifacts where the print head changes motion; or acceleration rates change because the need now traces a new knob or protrusion on a print level. But in my experience these are usually small but visible high or low spots. What your photo shows is the point where the part lifted and material was squeezed out horizontally. All plastics warp to some extent. Even PLA. In some cases adhesion keeps the part held down then releases and a part lifts a corner a mm or more. Sometimes the part lifts due to a dirty bed and slowly a corner comes up. Slow lifts can leave no visible trace except the bottom is no longer flat, but curved up from the bed. A round object makes it hard to see the lift happening; but it's there.

Put a straight edge across the bottom of the pot; you'll see the curvature. It's be about the height of that extruded band on the outside.

Here's an example of my bed temp mistake (also, bed was past due for a wash):