Need help with overhangs

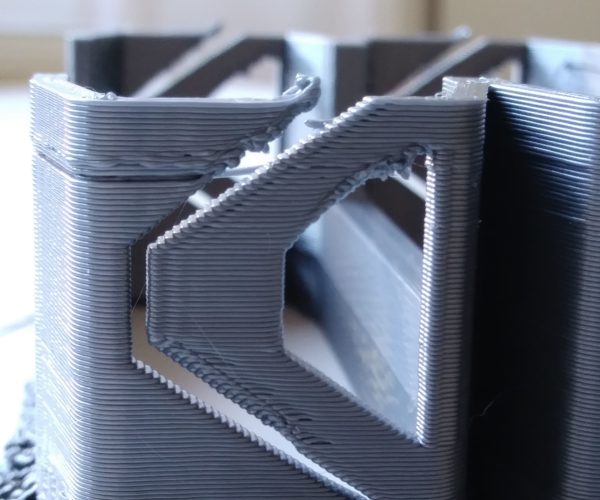

I've been having trouble with the overhangs in the model. This is prusament Galaxy Silver. The piece in this photo was printed with 0.3 mm layers, at 220 degrees. I've tried it at 0.2 layers and 215 degrees. I have to figure out how to make that edge stop curling up, otherwise the curling amplifies with each layer and ultimately the nozzle ends up catching on the curl and pulling the piece off the print bed.

RE: Need help with overhangs

Large thick layers and overhangs are not compatible.

Curl can be controlled with judicious application of temperature control (fan speed) and print speed (slowing down extrusion rates). Part orientation can also help.

And in the worst cases, supports can be used to provide a surface to better control artifacts.

RE: Need help with overhangs

Large thick layers and overhangs are not compatible.

Curl can be controlled with judicious application of temperature control (fan speed) and print speed (slowing down extrusion rates). Part orientation can also help.

And in the worst cases, supports can be used to provide a surface to better control artifacts.

Ok, I'll try shorter layers and a lower extrusion rate. Regarding fan speed, do I need more or less?

Edit: Where do I find the extrusion rate setting in PrusaSlicer?

RE: Need help with overhangs

I find reducing the cooling helps the extrusion cool evenly - even OFF in some cases - but it's a trade off between droop and curl. Dropping nozzle temp can also be part of the puzzle.