MK3S+ Issues with TPU Printing

I recently ordered a spool of TPU (via prusa3d.nl, Flex filament TPU 500g HotOrange3D).

When I try to print with this, the extruded blocks after about 3-5min of printing. The print is a basic circle shape object, nothing fancy (just a test). It correctly prints the perimeter, then starts to fill in for the first layer (0.2mm) and then after about 3-5 minutes of printing (about 1/2 first layer infill), nothing is extruded anymore. There is no error on the printer that the filament is stuck, it just continues to print but nothing comes out of the extruded.

Trying to unload the filament fails, I need to really pull it out by hand (with the nozzle heated, that seems to work and there is no blockage in the extruded).

Used with prusa slicer filament type Flexfill 92a, nozzle 240º and bed 50º

Any ideas here??

TPU

I have always found the challenge for me with TPU is getting the idler screw right. Not too loose and mot too tight. It takes a little tinkering with TPU.

--------------------

Chuck H

3D Printer Review Blog

Idler bolt

I find I don’t have to mess with idler bolt. As long as the tip of the bolt is flush with nut under hex window I don’t have to change it for pla or petg. Make sure you are using a filament profile thats type FLEX

Yup

+1 to @ssill2. Printing filamatrix tpu 95a without touching the idle thingies. Floppier filaments May be different.

Don’t trust forum advice.

Floppy ok

I’ve printed 85a with same settings

idler

I find I don’t have to mess with idler bolt. As long as the tip of the bolt is flush with nut under hex window I don’t have to change it for pla or petg. Make sure you are using a filament profile thats type FLEX

I concur once you have it set right.

--------------------

Chuck H

3D Printer Review Blog

To idle or not to idle..

Right so divided here.. don't touch the idler, or do change it? I will go thru the video from Prusa about the idler to make sure it's set correct.

Does anyone have a profile for slicer for TPU? I read that the main thing is you should not print to fast, however if I select the Flexfill profile, the normal 0.15 /0.20 settings still show a high speeds for printing (80 for infill) where as it's recommended to use speeds between 20-40?

interractions

Hi Martin ,

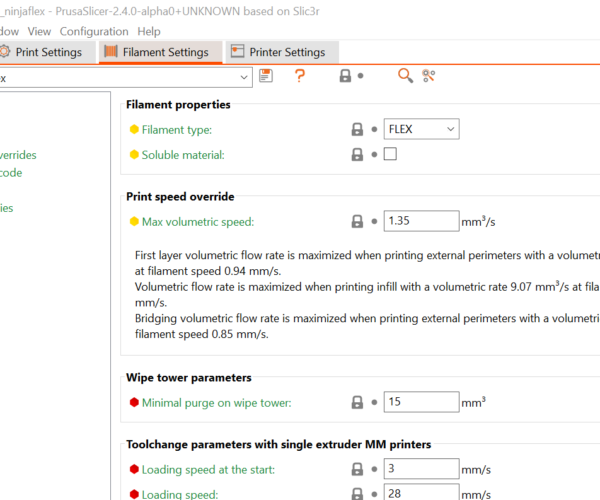

speeds are just one factor another is Maximum volumetric speed

this limits the printer speed when the printer starts to speed up.

In the standare Prusa Slicer settings,

PLA has a value of 15 cubic millimetres per second,

Semiflex has a value of 1.35 cubic millimetres per second,

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

idler bolt

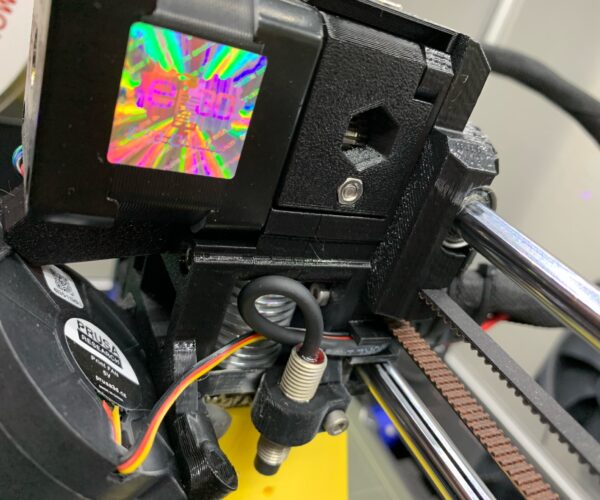

Here's what my idler bolt looks like and I print everything with it.

If you print with a profile where the filament type is set to FLEX it will automatically reduce all your speeds to like 35% and thus you don't have to mess with them in the print settings. The latest 2.4 alpha has a lot more options, but usually the Flexfill 98A is a good starting profile and you can save a copy of it and adjust things like temp etc to match your specific filament.

e.g.

When printing just make sure that if you're on smooth plate use glue since it can stick too well. The satin and textured sheets are great without a thing.

ilder

You should be good. That is the perfect tension on an idler screw.

--------------------

Chuck H

3D Printer Review Blog

Thanks

Thanks all for the tips. Not at home for a few days, will give it all a review next week when I am back.

No Joy

Had a moment to try, slightly better, that is instead of 5min, the print failed after 15-20min.

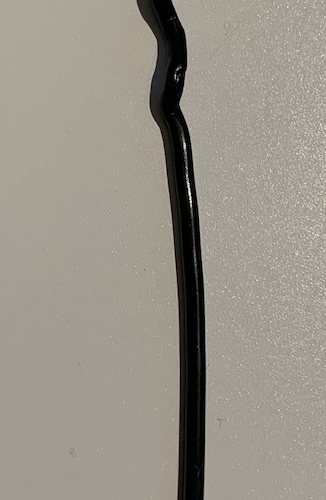

Have loosened the idler (also checked the alignment) but stil it blocks. It looks like it 'wrinkles' inside the bond tech mechanism.

I did noticed some posts with people having modified the MK3, but should that be really done? Any more ideas?

Up your temp

Lately with ninjaflex I’ve had to use 248C. Otherwise I get precisely that and stopped extrusion

drying tpu

I find drying TPU helps immensely, as does keeping tension on the idler as low as possible.

RE: drying tpu

I find drying TPU helps immensely, as does keeping tension on the idler as low as possible.

TBH most of these issues for me occur with shore 93A downwards. There are TPUs (I think the Prusa TPU is one of them) like Fillamentum Flexfill 98A and Extruder "Hard" TPU that are harder by nature and will print more readily on standard printers. You can still get the "rubbery" effect by printing with the lowest possible infill.