RE: Mk3s+ Getting Ninjaflex to work?

Hi there,

I am trying to get going with NinjaTek Chinchilla snow 1.75 (TPE 75A).

I followed the comprehensive settings suggested by @Swiss_Cheese however I encounter the following issue.

The print starts very good quality but after like 20-30 minutes and Z about 2,2 the filament is not coming out of the extruder but the filament is coming out of the side in the bondtech gear. If tried to loosen the gear but still after several attempts it stops almost every time on the same positon. Is this about the backpressure Swiss_Cheese was talking about or does anybody recognize another issue here? I would be more than happy to provide you with more info to get this issue fixed.

RE: Mk3s+ Getting Ninjaflex to work?

you could try increasing heat a bit. Any backpressure at all will cause it to to backup into the extruder. I've not tried the chinchilla yet, but the softer you go the more you have to worry about this. Think about trying to thread a wet noodle through the head of a pin. it wants to go everywhere but through. I've definitely found with later batches of ninja flex I have to go a bit hotter or I get what you described. I've been tempted to order a spool of that stuff to try it. Swiss is definitely the filament whisperer though so anything he has to say on the subject I'd listen.

RE: Mk3s+ Getting Ninjaflex to work?

So, I did manage to get Ninjaflex working *fairly* reliably. I printed I think 4 different models with it and only had one failure - but from memory (It was a while back now) that failure was a nozzle blockage instead of "filament fold"

I used the following resource to get it going, which really did seem to be the secret for my issues https://www.printables.com/model/12586-ninjaflex-profile-zero-stringing-flawless-print-be

However, I am now ALSO experiencing issues with printing with Chinchilla. I cannot get it going for love nor money, always suffering the dreaded filament fold. I have had one successful print out of maybe 30 attempts (And a lot of wasted filament)

The only print that worked was done at 5mm/s which is ridiculously slow.

Things I've tried:

I used the Ninjaflex settings from the above profile as a baseline

Turning retractions down from 6mm to 3mm

disabling retractions completely

moving to a 0.6mm nozzle (In an effort to reduce "filament back pressure" by forcing it through a larger hole)

Dropping all print speeds to 10mm/s

dropping all print speeds to 5mm/s

everything yielded the same result, filament fold at some random point a few layers into the print (Within 1 hour of starting every time)

Printing at 5mm/s did stop the filament fold, but the item came off the print bed part way through so I ended up with an unusable print; And I'd really like to print at more than 5mm/s if I can help.

I've been printing at 237c which is the upper limit for chinchilla. When you mention increasing temp, should I go to like, 240c? or a larger difference like maybe 255c or so? I had to put it down for a while out of frustration, but I'm ready to have another crack at it again now 🙂

RE: Mk3s+ Getting Ninjaflex to work?

I've been pretty busy with work so I've kind of slowed down printing for the most part. I haven't had a chance to try the chinchilla yet. @swiss_cheese probably has and, if true to form, gotten that working well. I'm kind of anxious for the XL to ship so I can try my hand and doing tpu prints with soluble supports!

So, I did manage to get Ninjaflex working *fairly* reliably. I printed I think 4 different models with it and only had one failure - but from memory (It was a while back now) that failure was a nozzle blockage instead of "filament fold"

I used the following resource to get it going, which really did seem to be the secret for my issues https://www.printables.com/model/12586-ninjaflex-profile-zero-stringing-flawless-print-be

However, I am now ALSO experiencing issues with printing with Chinchilla. I cannot get it going for love nor money, always suffering the dreaded filament fold. I have had one successful print out of maybe 30 attempts (And a lot of wasted filament)

The only print that worked was done at 5mm/s which is ridiculously slow.

Things I've tried:

I used the Ninjaflex settings from the above profile as a baseline

Turning retractions down from 6mm to 3mm

disabling retractions completely

moving to a 0.6mm nozzle (In an effort to reduce "filament back pressure" by forcing it through a larger hole)

Dropping all print speeds to 10mm/s

dropping all print speeds to 5mm/s

everything yielded the same result, filament fold at some random point a few layers into the print (Within 1 hour of starting every time)

Printing at 5mm/s did stop the filament fold, but the item came off the print bed part way through so I ended up with an unusable print; And I'd really like to print at more than 5mm/s if I can help.

I've been printing at 237c which is the upper limit for chinchilla. When you mention increasing temp, should I go to like, 240c? or a larger difference like maybe 255c or so? I had to put it down for a while out of frustration, but I'm ready to have another crack at it again now 🙂

RE: Mk3s+ Getting Ninjaflex to work?

We print a lot of Ninjaflex and Chinchilla. Back in the day the biggest change we made to get it to print reliably was to switch the extruder tensioning spring. When we print TPU we use a spring with less strength, doing that is so easy because no matter how you adjust the screw it will always work. We use the original spring when we go back to PETG/PC/ stiffer materials. Hope this gonna solve your issue!

Also be careful those materials tend to absorb moisture, we always dehydrate them weekly or so to have perfect result.

RE: Mk3s+ Getting Ninjaflex to work?

Oh really @gabriel? Where do you get that spring? Which did you use?

RE: Mk3s+ Getting Ninjaflex to work?

We use this one from Lee spring:

https://www.leespring.com/compression-springs?search=LC018B09M

We were able to test many springs since we have a lot of different type in house. This was the one we had the best result with. There is more than one good options out there, I'm pretty sure if you get a spring with almost the same specs you should be fine.

RE: Mk3s+ Getting Ninjaflex to work?

Thank you! I am trying out Ninjaflex for the first time on my MK3S+ and your advice helped me resolve a similar issue. I really appreciate the time that you took to provide this thoughtful response.

RE: Mk3s+ Getting Ninjaflex to work?

So did the weaker spring help anyone with chinchilla? Any other tips that people have? Thanks for your time!

RE: Mk3s+ Getting Ninjaflex to work?

Does this link take you to the exact spring? Looks theres quite a few options on that page. Thanks!

RE: Mk3s+ Getting Ninjaflex to work?

When I use the link it is exactly the right spring. If the link doesn't work you have the part number in the link.

Part number: LC 018B 09 M

RE: Mk3s+ Getting Ninjaflex to work?

I've struggled a lot to get Ninjatek Chinchilla to print on an MK3s+.

I've tried:

- lowering the tension of the spring

- testing various softer springs

- cleaning the Bondtech gears

- replacing the Bondtech gears with a fresh pair

- replacing the PTFE tube with a carefully prepared fresh one

- cleaning the Nozzle with a cold pull

- raising the temperature (way above the recommended value)

- testing bigger nozzle diameters

- tuning the speed down to ridiculous low values

- all the other usual things to get good prints like good calibration etc.

Nothing helped, all prints failed eventually - either because the filament was pushed out of it's path or because the filament got intermittently stuck (pressure buildup) and the gears started grinding it.

Well, I was ready to give up, thinking that despite some reports of successful printing with this setup, my particular machine (of my skills) weren't just not up to the task.

Then I received a Spool of Ninjatek Ninjaflex, wich - according to Ninjateks website - should be even harder to print than Chinchilla.

To my surprise it printed perfectly with the official Ninjaflex profile. Which is rather slow (1.2 mm3/s), but I've also tested 2.4 mm3/s and it printed again flawlessly.

That made me wonder if it's maybe a faulty batch I've received of the Chinchilla.

Upon closer inspection of the Chinchilla Spool I saw a lot of blobs and irregularities.

I sent some pictures and a description of my struggles to the dealer from whom I bought it and they immediately offered to replace the spool for free or to return my money.

I decided for the latter because of all the frustration I had with Chinchilla and out of concern the next spool might also be unprintable.

Just wanted to leave that as feedback to this thread because I've found a lot of useful information here, but I believe "faulty material" hasn't been suggested as possible reason for failed prints. Hopefully this will spare some of you the frustration I've experienced.

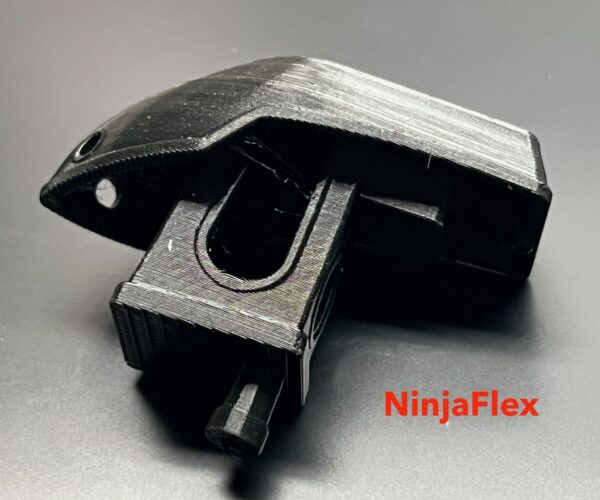

Pictures of the Chinchilla filament on it's spool and a Benchy printed with Ninjaflex (to show that the printer is capable of printing Flex):

RE: Mk3s+ Getting Ninjaflex to work?

I just got a roll of ninjatek, my first.

I'd just made some mk3 parts from sainsmart clear red which look tits as hell, so felt emboldened

reading this thread is sobering, and I'll give it a good visual

after it comes out of the dryer.....

they uh, they think that celloshrinkwrap is a humidity barrier? thats cute

silica packet in a cardboard box