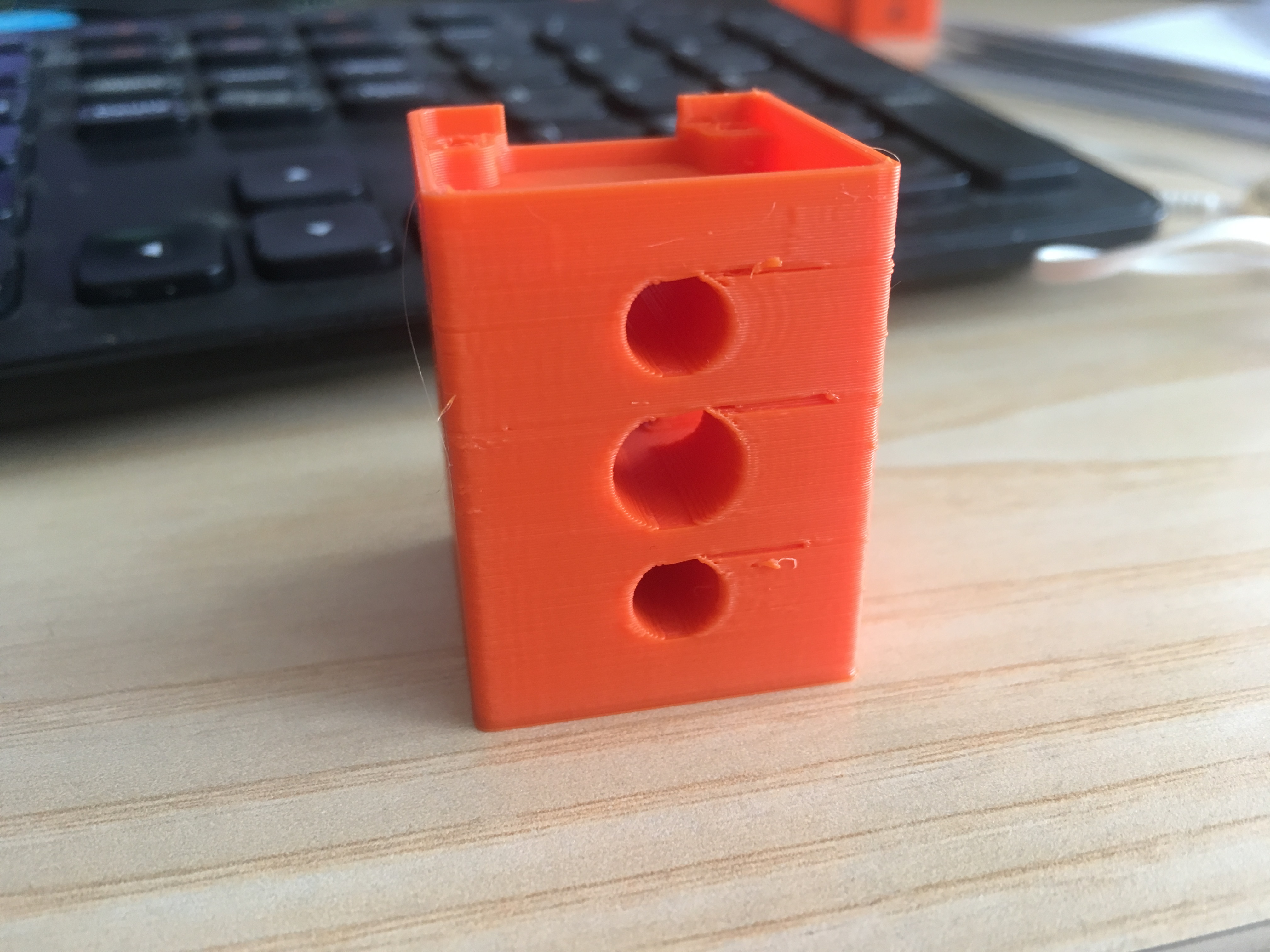

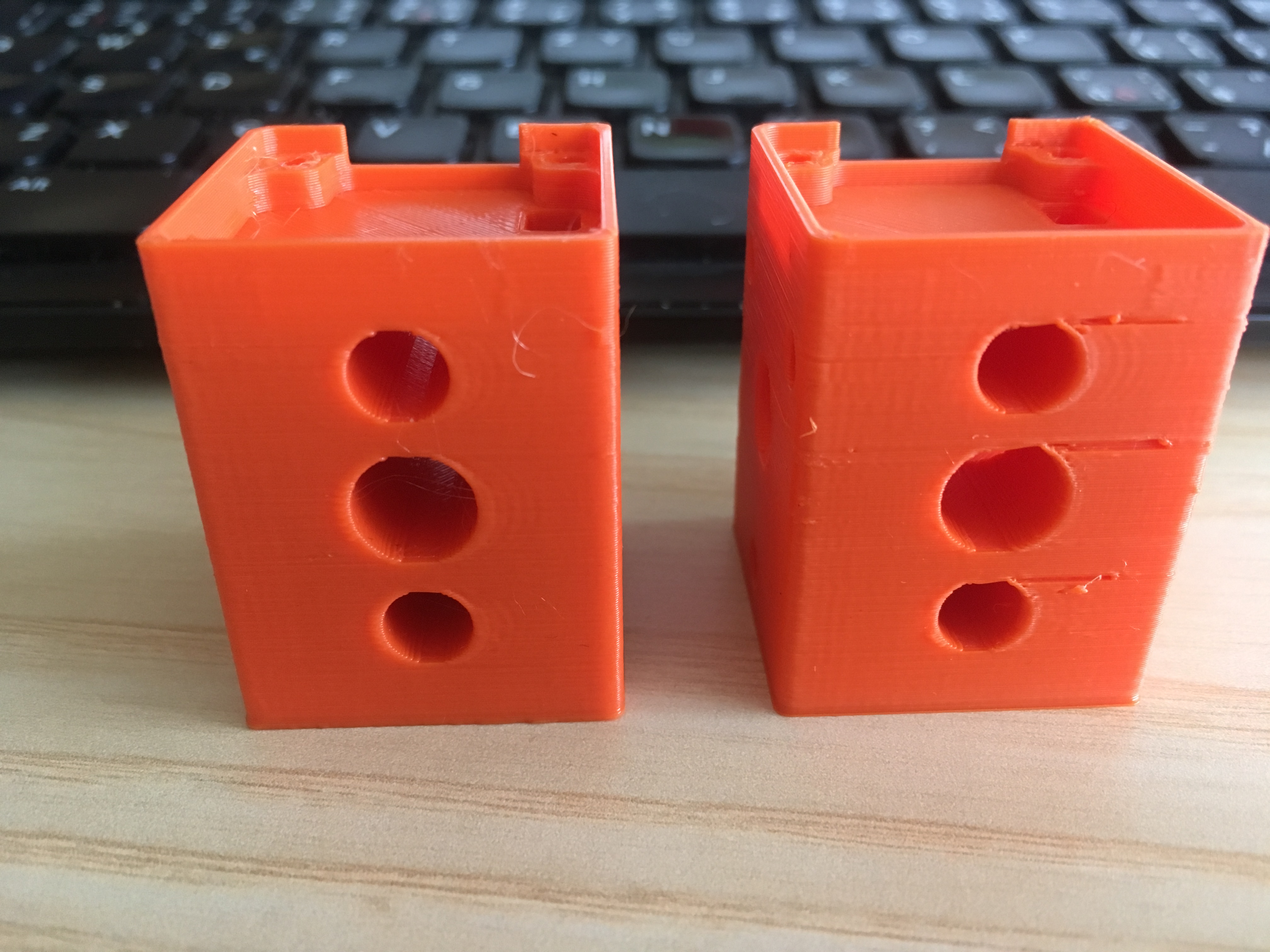

Re: Last hole layer problem

The top of a circular hole that's printed horizontally has unsupported layers that are at too steep an overhang angle to print successfully without support. You can get away with doing circular holes that are small, where the top half of the hole is only a few layers (Prusa does this in their printed parts for the MK3 structure), but bigger holes have more overhanging unsupported print zones.

Possible solutions:

1) Orient the part so the holes are vertical instead of horizontal. But in your case it looks like you will have some other overhanging places that may cause problems.

2) Allow the slicer to add support. But it will be difficult to clean out the holes after printing.

3) If this is a part that you designed (or can modify), and if the holes don't absolutely need to be perfectly circular, you could tweak the design of the top part of the holes to be more "printable", e.g. have straight lines for overhangs that can be printed, and a flat top that prints as a "bridge". As if the top part of the hole was shaped to fit a hex nut, for example. The modified design could either leave clearance for whatever goes into the hole as printed, or you could let the design shrink the opening a bit and then drill it out with a drill bit or reamer.

Re: Last hole layer problem

Thanks for reply, the problem is that this occur after upgrading Sli3rPE, even thou I have moved the settings, before It was printing fine same model. So I guess that there is some parameter that affects this which I omitted?

Re: Last hole layer problem

If only one hole had the defect, then I would have guessed that it was a minor clog that cleared itself. But it must be the slicer since all three holes are similar.

Did you change to perimeters first? The top of the hole has a very sharp angle that would be attempting to draw a line that barely touches the layer below. It could drop down and get in the way of the edge along the front face of the part.

Steve