Issues with stringing and other

Hello!

I am quite new to 3D printing and since I have setup my printer I have always stringing issues.

I use the Prusament PETG brand new, dry from the package. I use Prusa Slicer and the Prusament PETG profile there. I have set the retratcion length from 0.8mm to 1.2mm but with only little success. The printer runs in an enclosure so I also have pretty constant temperature. I also have sometime issues with some part of the filament seems to be pulled out of the object (first picture bottom right area).

Can you help me fixing this? I have the issues also with PLA and also tried to reduce the temperature a bit. At this moment I think maybe there is something wrong with the hardware. I have also changed the Nozzle already.

I have already applied a bit of hot air gun to the object to remove the thin strings.

Thanks!

PLA doesn't print well in an enclosure, leave the door open at least and perhaps direct a fan at the opening.

That object is a bit of a torture test for PETG. Try reducing the print speed and consider leaving the door open when printing that too.

Cheerio,

RE: Issues with stringing and other

That object is a bit of a torture test for PETG

Yeah, I was looking at the pictures before reading the text and thought "must be PETG". That's very typical. Follow @diem's advice. I also don't print PETG in a closed enclosure. I mostly use it for ABS and PC.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Just guessing

@dynamo

You could also try turning on "Avoid crossing perimeters" leaving it set to (zero) and see if that helps, (But maybe you did that I'm just guessing) and since just 99.99% of the people that ask for help here you didn't think to or maybe didn't know to, leave us a Zipped up .3mf project file . I'm going to have to guess that you were using the Prusament PETG profile for your print, and since that Profile has a built in filament override setting that you probably didn't know about? (I'm guessing here)

It wasn't allowing your changes to retraction to take place so you saw no difference, (also guessing) I'll bet if you tried to change the Z Lift that wouldn't work for you either, well that's all the guessing I have in me for the day.

Good Luck

Swiss_Cheese

The Filament Whisperer

Retry

Thanks for all the information.

So I created a new generic PETG profile and adjusted the temperature a little lower and activated "Avoid crossing perimeters". Also deactivated filament override of the printer settings. Now I can't even print the object completely and have more stringing 🙁

3mf File:

Dry your Filament

@dynamo

For starters, the model you shown when you started this thread is not the model your showing trouble with now.

Each model has it's adjustments that need to made to get the best result, that's where slicing software comes in, if your new to printing it's not a good idea to start by changing your default settings. in a very general way they will help you to get started and as you learn more move on from them.

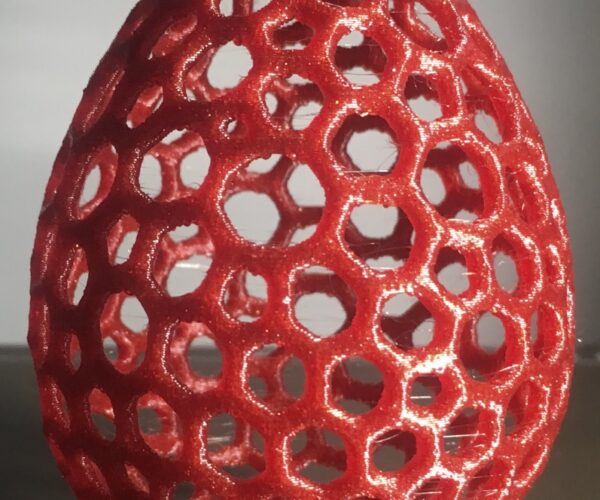

In the case of the first model you shown, "Avoid crossing perimeters" would be beneficial to the print, this newest model is the polar opposite. The Voronoi model is basically a torture test for stringing, and PETG is known for stringing, add on top of that, then changing the default settings, I'm not surprised at all that print failed.

So in order to help, I printed an example of what you might expect this to print like with default settings, as well I'm including the .3mf file I used to print it. I did change a couple things in order to help it print cleaner because its so small, but I did not change the filament profile.

This was printed with (DRY) Prusament Carmine Red (PETG)

during print

Completed (No Post processing)

Wisps removed, I put it on a pencil and spun it for only a couple seconds over the flame on my gas oven.

This was a 2h 13min print using 10.8 g of filament.

From the look of the last print you shown I think you may need to dry your filament. Filament will absorb moisture from the air and it can greatly effect print quality, PETG should be dried for aprox. 3 to 4hours between 65C & 70C.

Let us know how things turn out, and keep in mind it's always easier to get help with the zipped up .3mf files in conjunction with images showing the issue.

Good Luck,

Swiss_Cheese

The Filament Whisperer

Thanks!!!

Ok understood and thanks for the intensive help and even the print that you did!! I will try print it again with your settings and post it here. Regarding moisture, the filament is very new and I stored it separately in dryboxes at 30% humidity. I have 50% humidity in my room while printing. I think this shouldn't be an issue.