Issue with build plate adhesion following upgrade from MK3S to MK3S+

Hi Everyone!

I ran into an issue after upgrading my Prusa MK3S to the MK3S+ (Upgraded everything except the Y axis components). Since making the change, I have not had much luck with build plate adhesion. I'll start the print job and before I can even get the first layer down, the filament starts coming off the bed and sticks to the nozzle of the printer. The filament I am using is Prusament PETG.

Immediately after the build, I had run a successful Selftest and no issues came up during the XYZ calibration. However, I can't even get the filament to stick to the bed during the First Layer Calibration procedure. These are the other steps I have tried:

- Adjusting nozzle temperature

- Adjusting bed temperature

- Adjusting the height of the nozzle (tried First Layer Calibration and Live Z Adjust)

- Slowing down the print speed

- Checked the filament to ensure it had not absorbed too much moisture

- I tried running the Mesh Bed Leveling procedure with 49 points

- Inspected how the filament loads into the extruder

- Checked the tension on the Y and X axis belts

- Cleaned the print bed with alcohol to remove debris and improve build plate adhesion

- Cleaned the area around the nozzle and made sure there was nothing clogging the inside

I'm not really sure what else to check at this point as almost no filament seems to stick after the printer pushes out the purge line. Prior to the upgrade, I had nearly two years of excellent printing with a variety of materials (including Prusament PETG). I am besides myself on this one.

Has anyone else ran into this issue? If so, how did you solve the problem? Is there something else you think would be worth trying on my end that hasn't already been done? Any help would be greatly appreciated.

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Do a first layer calibration and post photos here, give us 2 photos, one of the full build plate and a close up of the rectangle at the end.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Hi Bob,

Thank you for taking the time to help me troubleshoot this issue. Unfortunately nothing seems to stick to the build plate after the purge line so you won't see the zig zag of the first layer calibration. Usually by the time it gets to the part where it would make the rectangle, the outside of the nozzle is covered in filament and nothing coming out is even touching the build plate.

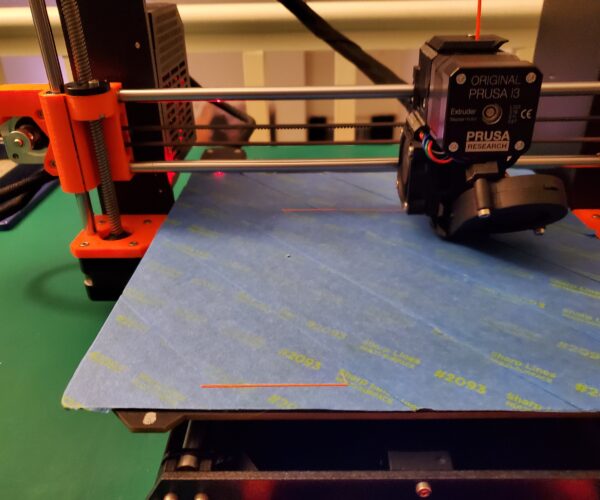

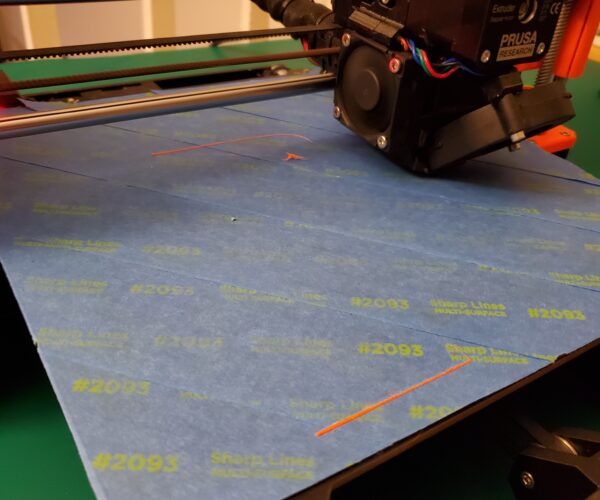

As a frame of reference, you can see in the attached images that not much appears to stick to the build plate after the purge line. It doesn't even make it through the first line of the zig zag pattern. You may have noticed that the build plate is covered in blue painter's tape in the photo. I tried this same procedure without the painter's tape on the build plate and the results were exactly the same.

This is pretty much as far as the first layer calibration gets before the filament stops sticking to the bed. The printer is sitting on a level surface, I ran a 49 point calibration, and I rubbed down the print bed with 91% isopropanol to improve build plate adhesion.

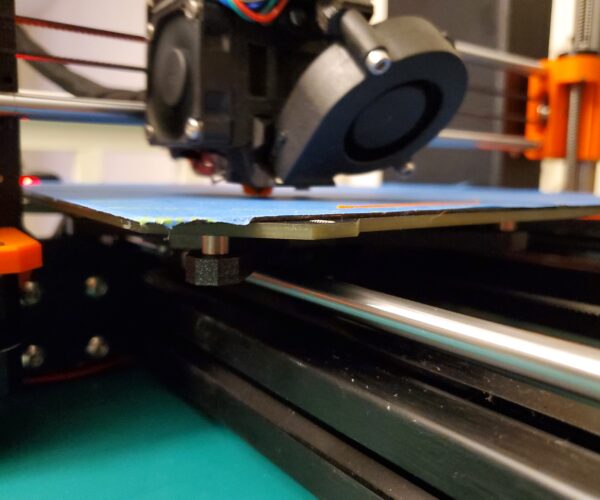

As you can see, the filament is building up around the outside of the nozzle. At this point in the first layer cal. the printer should be trying to print the rectangle.

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

What is on your build surface? Do you not have official Prusa plates? All you need are the original smooth or textured steel build plates.

Regards

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Live z looks wayyy too low.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

It's painter's tape that's on the surface. It is in fact the original build plate which comes with the printer (smooth and not textured). It's something I started doing years ago to make my life easier when printing with PETG. I tried running the first layer calibration on the build plate without the tape and had the same results unfortunately. Had thoroughly cleaned both sides of it before the calibration. No luck.

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

I use PETG on my printer all the time, I've never had problems getting a print loose. Usually I just let the bed get to room temperature and it pops off all by itself.

Take off the tape, clean the bed and learn to do this right, you'll thank us.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Bob,

I have tried all the things you just mentioned and ended up with the same results. It didn't make a difference. Clearly that is not the issue. Prior to the upgrade I had nearly two years of flawless printing with Prusament PETG filament on this printer, so it's a strange feeling to be struggling with this now. Look forward to using my printer again.

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Hi fuchsr,

I tried raising the live z a little bit during a cal. this morning and it appears I am still honing in on the "sweet spot." I think it's helping, but not quite there yet. It seems the filament always starts to lift off from the bed in the same location which is about 3/4 the way across the x axis. I noticed that there is a strange noise (almost like a rattling) coming from the extruder when it gets to this position. Have you ever run into this issue?

I wasn't sure what it was, so I tried tightening the screws to the plate which secures the x axis bearings to the body of the extruder and applied some 3-in-one ptfe lubricant to the x axis smooth rods. Since making the change I no longer hear the noise and the first layer cal. is looking better as more filament is sticking to the bed. The results are encouraging, but have me double checking the assembly.

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

well some how you missed something, blue tape is a long gone issue for adhesion, you should defiantly take the time to figure out whats up, and move on. I own multiples of all three types of Prusa sheets and in 5 years have never needed to add tape to any of them for adhesion, or proper first layers. It seems like your stuck in the past.

The Filament Whisperer

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Bob,

I have tried all the things you just mentioned and ended up with the same results. It didn't make a difference. Clearly that is not the issue. Prior to the upgrade I had nearly two years of flawless printing with Prusament PETG filament on this printer, so it's a strange feeling to be struggling with this now. Look forward to using my printer again.

You clearly have a right to pursue this hobby any way you like, but putting painters tape on your bed is a solution circa 2015 and is throwing an extra variable into your adhesion issues. If you're dedicated to continuing along path that's your choice, you have to live with it, but it's not a puzzle I wish to try and solve.

Regards

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Hi Bob,

I ditched the tape, cleaned the print bed, and still got the same results. I even tried using a brand new smooth PEI sheet (NO TAPE) and had the same results. Decided to return back to the basics and use PLA for the calibration. Adjusting the nozzle height and bed temperature has resulted in some PLA filament sticking to the bed, but it seems the results varied across the print bed. Tried cleaning the brand new print bed, but had the same results. Keeping myself eye-level with the print bed during the first layer cal., it looks as if the tip of the nozzle is a higher off the print bed as the extruder travels across the x axis. I tried tightening the x axis belt, but that didn't change anything. Also tried checking that the z axis is level, but that looks good too.

The next thing I tried was running a Bed Level Test ( https://www.prusaprinters.org/prints/36706-bed-level-test) with PLA. The square in the top right corner of the bed looks perfect, but the one in the bottom left corner (closer to the LCD screen) has that wavy look to it. Tried tensioning the the y axis belt, but that didn't seem to change the outcome. The filament still seems to be in good working condition, but something seems off with the printing. I'm looking at what might be needed for bed level correction and double checking the extruder to see if something went awry during the assembly. More information to come!

Chance

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Post some photos if your first layer calibration so we can see what you're seeing.

Regards

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

Hi Bob,

Since my last post I tried loosening the screw for the panel that presses up on the bondtech gear within the extruder assembly so it could rotate more freely. That seemed to improve the consistency of the extrusion. The other thing I did was increase the bed temperature by 15 degrees Celsius above what I had used for the previous first layer cal. with PLA. That seemed to do the trick as the filament doesn't seem to be going anywhere now when I run prints. The first layer cal. I ran following the change looked solid.

As I wanted to build some confidence in the printer after making the adjustments, I decided to run a benchy print.

This was printed with CPE (it's a generic co-polyester blend so it handles like PETG). Based on what the outcome of the print I think we can call this case closed for now. Thank you for helping me solve the printing issue.

Chance

RE: Issue with build plate adhesion following upgrade from MK3S to MK3S+

I'm glad you worked it out, that's a respectable benchy.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit