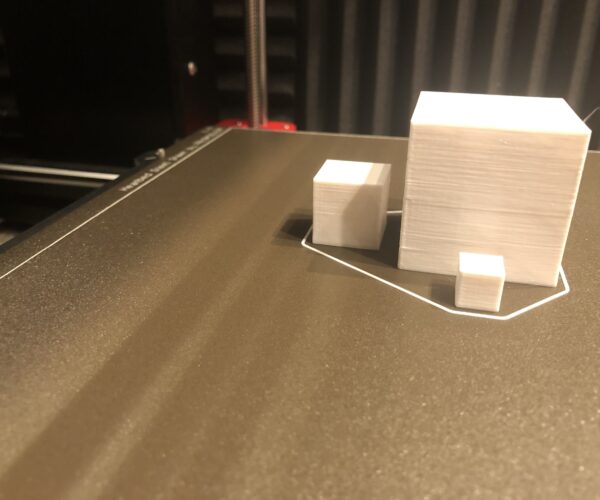

Is this the quality you get with PETG?

Hi all,

attached you see one of my latest (test) prints with Prusament PETG. I recently discovered an uneven surface - when the lighting is right - with PETG prints. Is this a normal phenomenon or is there anything wrong (--> Z-banding)?

I checked the belt-tensions to be in the given range, at the moment they are around 260 when using the built-in test. I also tried to tighten the bed a bit more but there was not much to tighten.

Thanks for your input.

It's not the quality I get, my opinion is that the number produced by the firmware measurements are pretty much worthless, I recommend downloading and printing the belt tension device from "Prusa printers" and printing it in Prusa PETG, then measuring your belt tension with the device. prehaps someone here can provide a link to the print as I haven't been able to access prusa printers for months now. I don't personally use this device however many here say it works very well.

Regards

Swiss_Cheese

The Filament Whisperer

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

Works great!

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Looks good to me.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Did you print it with Prusament PetG?

The readings are only valid if printed with Prusament PETG.

So, tell us about those cubes - are they simple calibration cubes? Something you designed yourself? Hollow? Can't tell much from just a picture - but yes, you can do way better than that. The filament type hardly matters.

RE: Some more context

Thanks to you all for your help first of all.

So here is some more context: Yes I am printing with Prusament PETG. The effect is visible the most with PETG, with PLA it is not that extreme. I didn't try ASA til now, maybe I can print the test objects with Prusament ASA later this evening.

I included the .3mf file for the test cubes. Yes they are just plain 20mm calibration cubes I scaled to 200% and 50% for comparison. For infill I went with 15% adaptive cubic, but I found out that it does not really matter that much. Looks the same with gyroid and/or 20%.

Here is another print that i did to eliminate the hull effect (printed with all the same parameters like in the given .3mf). I tried to get the light in a way that the problem is showed the best, sorry for the bad quality, it's the best my phone camera can do 😀

Attach files?

How can I add a file? Whenever I attach the .3mf it is not visible in the published post?

Zip It!

Forum only allow zip-files

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.6.1+win64, Fusion 360, Windows 10

play around with your Live Z

I'm only guessing, as I'm not nearly as experienced as are others here, but you might try decreasing your Live Z (more negative) to get the layers to squish more together.

@lukas-6

No, that's not how PETG print (or any filamet type) should look alike: flat walls must actually be flat and silky smooth. Or let me put it differently... it should look better than printed parts of your Prusa printer. But I'm sure you already guessed that -otherwise you would ask this question here.

Prusament PETG is an excellent filament (darn, I should get a free spool for saying that 😊 ). But it needs to be dry!! Don't say it's new spool, dry it properly instead. You make no changes in adjustments or settings until you dried it.. ok?

Now, if you still don't get expected results (after you dried the filament!), maybe you should make extruder calibration. By doing this, you actually don't change anything -you only check, if the correct amount of filament is being "pushed" by extruder.

The thing is, these issues must be solved step-by-step .. makes no sense to apply multiple (guessed) changes at once.. you need to isolate the cause.

[Mini+] [MK3S+BEAR]

Live z only affects the first layer, the thickness of subsequent layers is driven by layer height.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

The readings are only valid if printed with Prusament PETG.

I know that's that the description says. And it's what I have done myself. But I'm wondering if anyone has actually confirmed that experimentally? I can certainly see why i can't substitute PLA, but I'm wondering what would make Prusament PETG special. Sure, I can see how additives can make a difference but to what extent? I'm out of town but I may give Overture PETG a try, just to see if it indeed matters.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

@lukas-6

I'd like to point out that, at least from your picture, the tension meter seems to look Ok in print quality.

I would like to see the .3mf you tried to post earlier, if you can figure that out.

Regards

Swiss_Cheese

The Filament Whisperer

thanks

Thanks for the clarification, fuchsr.

...But I'm wondering if anyone has actually confirmed that experimentally? I can certainly see why i can't substitute PLA, but I'm wondering what would make Prusament PETG special. Sure, I can see how additives can make a difference but to what extent? ....

Well, this "tension meter" isn't some precise instrument... is more a "helper" for those who don't have experience with 3D printers.. or simply lack the needed feeling. I'm pretty sure that most "normal" PETG filaments would do the job as well.

What I don't like about this particular print object is the fact, that it is given in Gcode. And so it's practically useless for all those who upgraded their printers... that is, I could confirm that at least in case of Prusa Mini. The thing is, inside Gcode, extrusion (E-step value) is defined -which is very bad practice in general.

Just sharing my thoughts...

[Mini+] [MK3S+BEAR]

There goes your free roll of filament 🤣

@bogdanh

You might still be a contender for a TEE- Shirt though.

Well, this "tension meter" isn't some precise instrument... is more a "helper" for those who don't have experience with 3D printers.. or simply lack the needed feeling. I'm pretty sure that most "normal" PETG filaments would do the job as well.

What I don't like about this particular print object is the fact, that it is given in Gcode. And so it's practically useless for all those who upgraded their printers... that is, I could confirm that at least in case of Prusa Mini. The thing is, inside Gcode, extrusion (E-step value) is defined -which is very bad practice in general.

Just sharing my thoughts...

I agree, on both counts.

Regards

Swiss_Cheese

The Filament Whisperer

Regarding Drying

I heard about drying now several times. I am currently not at home but i will try to do that.

My oven is not one of the most modern ones, how warm can the ambient temperature get until i ruin my filament? I am a bit concerned about that point ...

Regarding 3mf

I will send the file once i get home. If the lighting is right the tension meter does not look very different to me though ... but i will send it.

Unless you have a modern oven with a tight temperature control, don't try it. I know from painful experience.

just Google for filament dryers. There are dedicated one (I use the PrintDry Pro), or you can convert a kitchen dryer.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/