RE: Help printing with FlexFill 98A

@fscheps

Also sorry I should have explained better. For the screenshot I mean the sliced model in Prusaslicer to show the first "bridging layer" on top of the button holes.

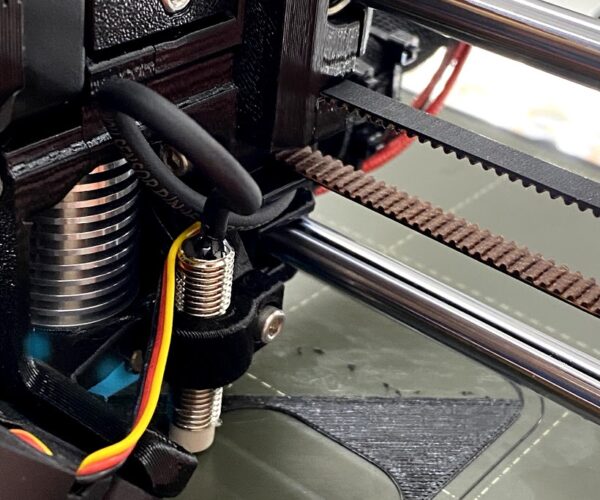

On another note, that is how my prints were before adding the fan. They would fail a certain time into the print every time. With the fan I was then able to print full models and add longer retractions and increase the speed of the retractions.

RE: Help printing with FlexFill 98A

@halcon-designs

Thanks! So for now, should I completely turn off retractions until I can place the top fan? And once I have the fan which retraction settings are you using?

RE: Help printing with FlexFill 98A

I'd suggest not printing with flex until you get the fan installed as it's unlikely you will get the quality you want from flex without retractions enabled. However, if you do want to print with flex in the meantime then you are right, turning retractions off will reduce your chances of a jam.

I currently don't use Flexfill 98A, but when I did I had full 2mm retractions at 45 mm/s. I wouldn't suggest using these as there is a bit to go, I was planning to use "wipe while retracting" to further reduce stringing, but I have moved on to 95A TPU in the meantime as it better fits my use case now.

RE: Help printing with FlexFill 98A

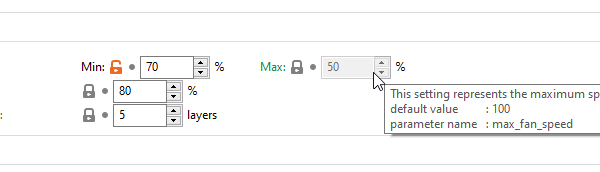

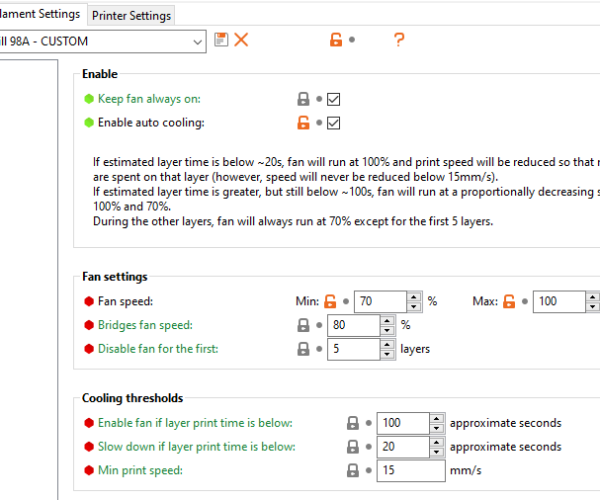

I am a bit confused, Its probably a rookie question, but how do I change the Max cooling setting? I cant find the way to unlock this on this profile :/

Also what should the "bridges fan speed" and disable fan for the first "X" layers parameters should be set to?

Thx!

RE: Help printing with FlexFill 98A

@fscheps

Have you enabled "Enable auto cooling"?

RE: Help printing with FlexFill 98A

@halcon-designs

👍 now it works 😉

I swear I tried to search for the answer before posting, but couldn't find anything :/

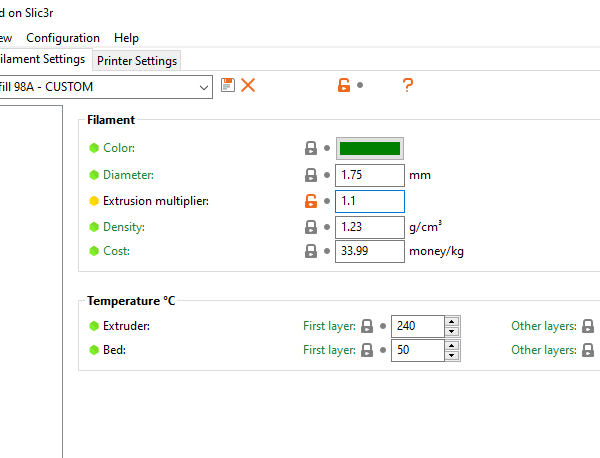

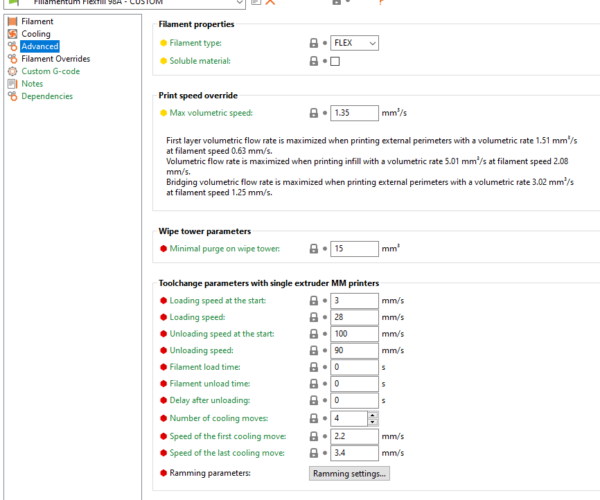

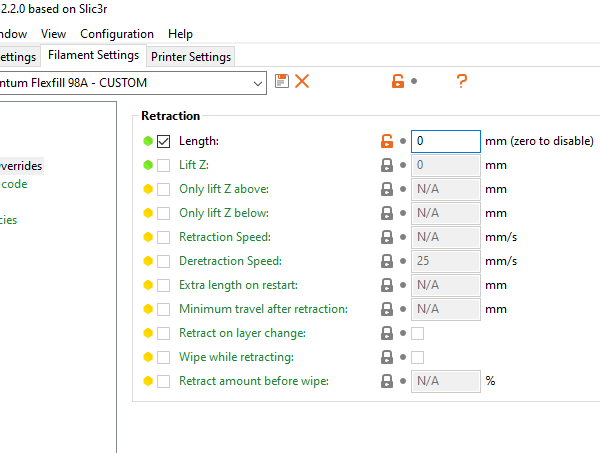

So My parameters are like this:

Does this look promising? Anything else should I touch before trying again?

RE: Help printing with FlexFill 98A

Do the above parameters look ok to you?

RE: Help printing with FlexFill 98A

@fscheps

Looks fine to me, as I said I'm still quite new to 3D printing. To help with the bridging maybe up the bridging fan speed to 100%. But as I said the best way to sort out the presets is to test each setting after you upgrade.

Good luck!

RE: Help printing with FlexFill 98A

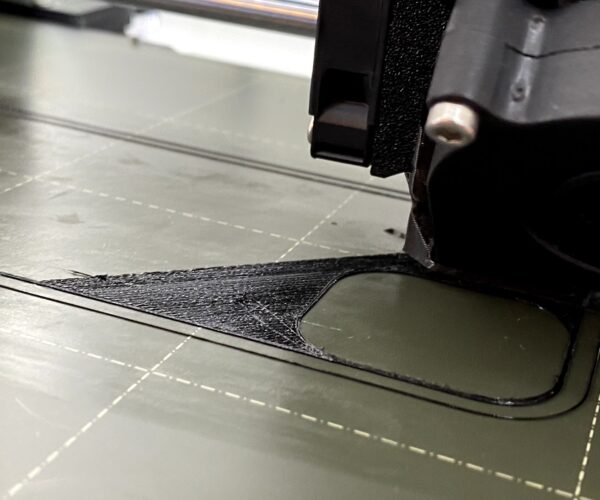

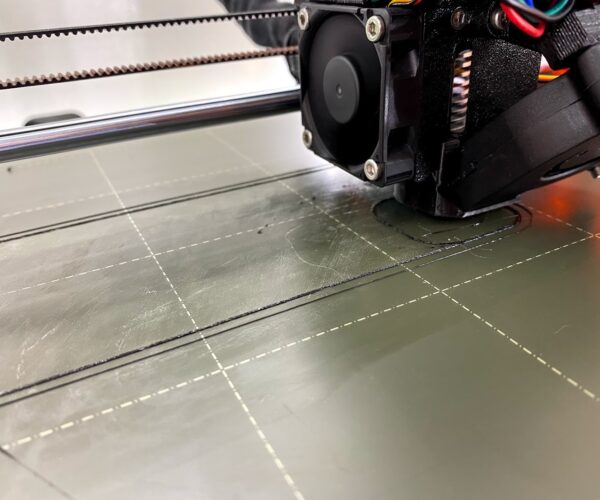

I tested these settings and the results seem to be worse than before :/

Also even when the printer is calibrating itself (7 points) I have to go and clean the surface removing all the "Filament little blobs" that are left from the measurements. This cannot be normal :/

Any ideas? 😪

RE: Help printing with FlexFill 98A

@fscheps

Looks like your filament might have absorbed moisture from the air, do you keep it in a dry box?

RE: Help printing with FlexFill 98A

@fscheps

Filament leaking during the calibration is normal. I used to run flexfill98A at 230 degrees to help with bridging, it also reduces the amount of material leaking. You can stop this using another startup G-Code that finishes heating the hot end after the calibration is complete, but this is bit more of an advanced feature.

RE: Help printing with FlexFill 98A

@halcon-designs

Hi there, this would be quite unrealistic, I opened the box (sealed) yesterday. I live in Switzerland which is pretty much a dry place. Now I have 41% humidity inside the enclosure after trying a print. Its 27 degrees today a bit hot.

But if this filament is already absorbing moisture in less than 24 hours of opening the box, the its almost impossible to use :/ could it still be the problem?

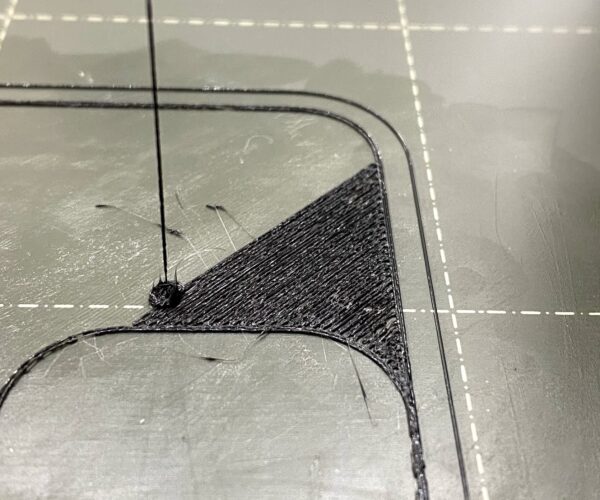

I tried again with all speed parameters to 15mm. Awful results:

RE: Help printing with FlexFill 98A

@fscheps

From the settings you have changed only the extrusion multiplier comes into effect on the first layer and, if anything, it should just leave gaps between there infill and perimeter if it is too low.

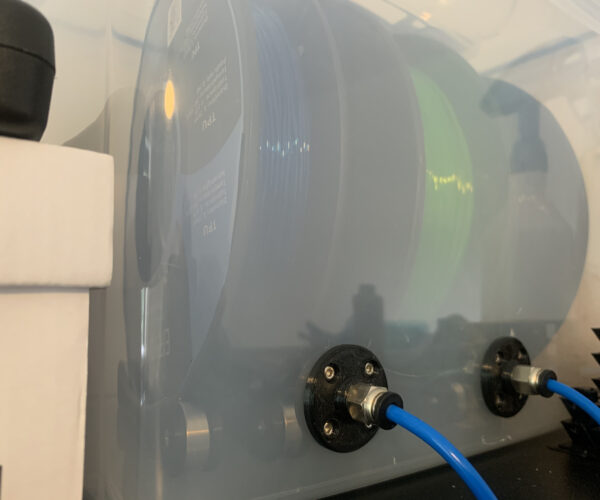

As a resident of the UK I can verify humidity is a problem at our latitude. I have attached an image of a couple of my prints, one before drying (closer of the two) and one after. As seen the one printed with a high moisture content has a similar texture to the image you provide. I print all TPE/TPU and PET-G directly from a DIY sealed dry box that is ~10% humidity and store all filaments not in use in a large sealed box of the same humidity.

Dry and damp Flexfill98A:

I hope this helps. If it is any consolation I went through all of the same problems...

RE: Help printing with FlexFill 98A

@fscheps

Also one telltale sign of high moisture content in the filament is you will hear a crackling sound as the filament comes out of the nozzle.

RE: Help printing with FlexFill 98A

@halcon-designs

Thanks for sharing, lovely box, looks like the IKEA Samla with some adaptations. Did you follow any guide to maintain low moisture on your filaments so I can have a look how to build such a box and how to seal it properly and maintain low humidity on it? Enclosure is positioned in a quite high furniture, It would be quite challenging to place filaments on top even in a box, but I could try.

I honestly didn't know this material could be such a pain to print...

RE: Help printing with FlexFill 98A

There are plenty online if you search filament dry box. I also provide instructions on building the one I use here:

https://www.prusaprinters.org/prints/28291-dry-box-filament-valve

I run the filament spools off of my own rollers here (with instructions):

https://www.prusaprinters.org/prints/26233-filament-spool-holder

Recently I have bought a larger sealed box from a company in the UK for the rest of my filament rolls:

https://www.solentplastics.co.uk/70-ltr-xl-iris-airtight-clear-plastic-storage-box/

They also have Amazon and eBay accounts. However, it will probably be cheaper to seal your own box like this one:

As for how I run it, I have built an open lack enclosure (no Plexiglas glass installed as of yet) and run the filament feeding tubes through the middle of the top table straight down to the printer.

RE: Help printing with FlexFill 98A

@halcon-designs

Again, thanks a lot! Will have to try with it dried 🙂 Lets see how it goes

I have an unoppened box of Flexfill 98A in red, but if I open it and I dont have a place where to keep it dry while printing., I am going to suffer of the same issues in the middle of the print right?

RE: Help printing with FlexFill 98A

@fscheps

Probably not mid print, but after a day then yes especially if it has the same properties as the black.

RE: Help printing with FlexFill 98A

@halcon-designs

Ok, so I am buying the parts to build the dry box 🙂 Thanks

RE: Help printing with FlexFill 98A

@fscheps

No problem! Hopefully you will get printing TPU soon.