First TPU attempt - needs work...

This is my first attempt at TPU. Fillamentum FlexFill 92A. I used the default PrusaSlicer 2.6 profile for this filament, 0.2mm layer height, but it needs a bit of work...

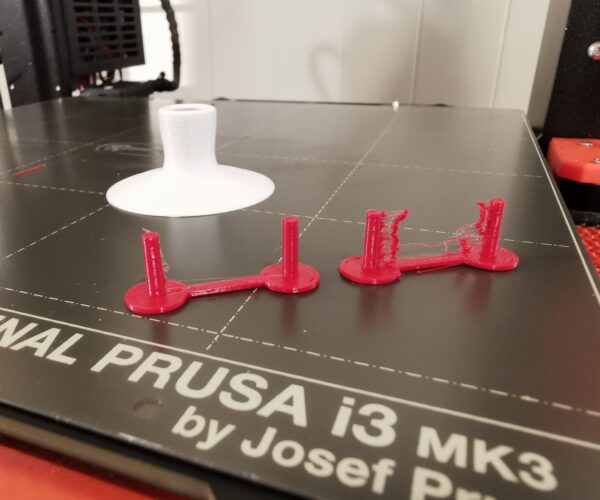

Lots of stringing.. Create a retraction test print here and increase retraction.

Then, surface looks rough.. Lower temperature (it was 240C)? Set all speeds to 20mm/sec, possibly. Print temperature tower after retraction is improved.

Then? We'll have to see after those two issues have been improved.

Best Answer by n808:

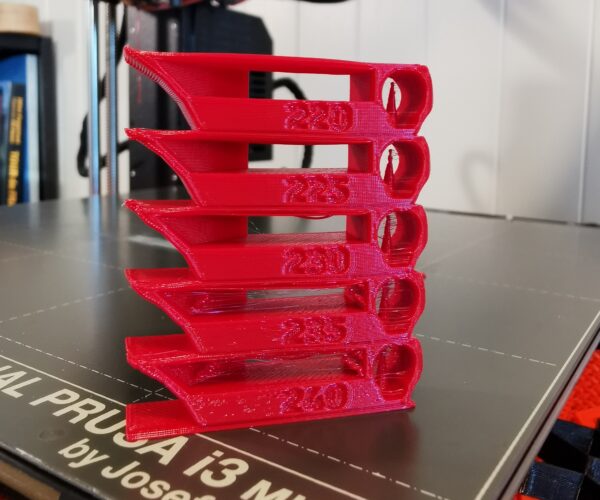

Nope, even at 220C, retraction needs to be 1.4 (and Lift Z 0.2, but might not matter).

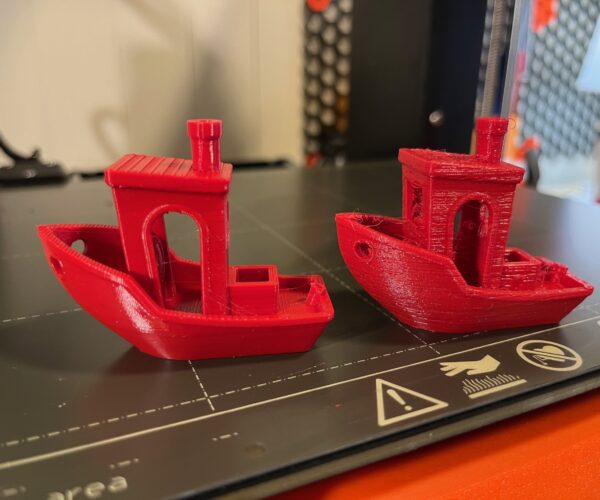

Below Left, Retraction 1.4mm, Lift Z 0.2mm. Below Right, Prusa default for this filament Retraction 0.4mm, Lift Z 0.

I think I consider this good enough. Summary: Fillamentum FlexFill 92A needs 220C, Retraction 1.4mm, Lift Z 0.2mm.

RE:

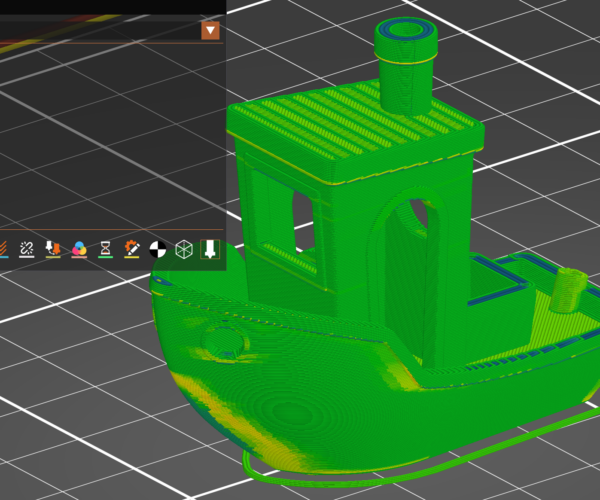

The default Filamentum FlexFill 98A profile sets the max volumetric speed to 1.35 which makes reaching speeds above 20mm/s difficult in the first place... And the rough patches do not line up with the fast areas.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE:

Thanks, good point, 92A has even slower max flow rate, 1.2 mm2/sec. I won't have time to work on settings for a bit, but I'll start with temperature and retraction, and see how it improves. First time I have tried anything that doesn't print well with default profiles, but TPU is of course more difficult than various form of PLA and PETG 🙂

RE:

Don’t expect that a TPU Benchy looks as nice as PLA, it never will. Some stringing and rough overhangs are in the nature of the beast.

First suspects for lots of stringing are : 1- Nozzle temperature too high 2 - Moisture.

I haven’t experience with Fillamentum Flexfill92 but, if it serves of guide, I print Esun TPU95 at 220C for the first layer and 210C for the others.

TPU absorbs humidity very fast. Even with a fresh new spool from a reputable manufacturer, there’s no guarantee that the filament is dry. If you have access to a filament drier or food dehydrator, give it a try.

Don’t overdo the retraction length. If a setting of 2mm maximum. doesn’t alleviates noticeably the stringing, don’t go higher or you might experience heat creep and jams.

A volumetric speed of 1.2mm3/s is very conservative and probably you can go higher, but it won’t harm to be cautious in this regard until you have stringing under control.

RE:

Thanks, @Artur5. I figured PLA quality like Benchies would not be possible, but with lower temps stringing and surfaces already look much better! Surfaces went from very rough to perfectly smooth. I set retraction to 1.4 from 0.4mm for the temp tower, and can probably set that back now, as it appears the temperature suggested by PrusaSlicer default profile for that filament was the main problem. I don't think I need to dry the filament yet. I keep all my filaments in dry boxes with re-usable desiccant so it should last a while.

RE: First TPU attempt - needs work...

Nope, even at 220C, retraction needs to be 1.4 (and Lift Z 0.2, but might not matter).

Below Left, Retraction 1.4mm, Lift Z 0.2mm. Below Right, Prusa default for this filament Retraction 0.4mm, Lift Z 0.

I think I consider this good enough. Summary: Fillamentum FlexFill 92A needs 220C, Retraction 1.4mm, Lift Z 0.2mm.

RE: First TPU attempt - needs work...

My best advice for TPU: dry the hell out of it. Then dry it more. Then print from the dry box. And don't say "it was fresh out of the vacuum bag", "it's in a container with desiccant", etc; doesn't matter (much). The difference in stringing and surface quality is mind boggling.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Almost, if not the same as, PLA quality, except perhaps cabin window front overhang. No drying, fresh out of vacuum, it must have been manufactured recently. Will store in 5% humidity box as per hygrometer, but I have no room on desk to dry while printing, so I will dry in oven as per TPU recommendations after a long print and maybe before. After settings tuning as described above (left) and before (default PrusaSlicer preset for filament) photos.