First ABS print

Advices and comments appreciated on improvements I can make to my first ABS small print please. It's a model I created in Fusion scaled in slicer at 70% size.

Printed using Prusa basic ABS in silver using PrusaSlicer filament stock settings. Brand new out of the packet but I thought it looked a bit bubbly when I loaded it, haven't got a dehydrator so think I may get one.

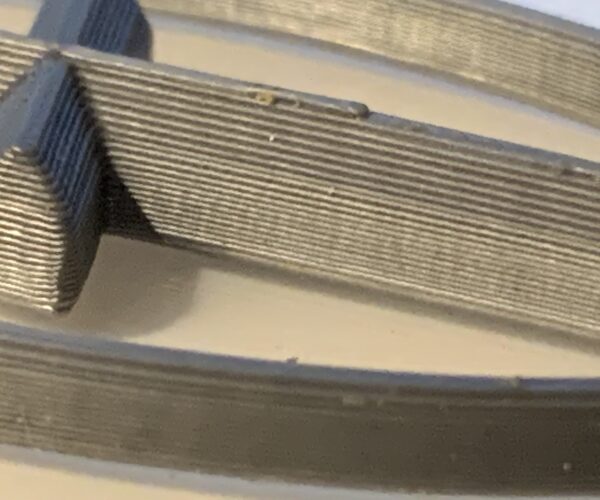

Printed at 0.2 Quality layer height, 15% infill with 5mm brim plus fiddled with perimeters to get the top of the balls looking better than the infill showing though.

Used smooth sheet with some glue stick, adhered well but even on this small print one part lifted ever so slightly. I let it cool to nearly room temp before removing, was slightly more tricky to get off the bed than PLA/PETG but not difficult.

Raised live Z by 0.002 but not sure I should have done that and wondering if this is why the layers don't look particularly squished or if a higher temperature is needed.

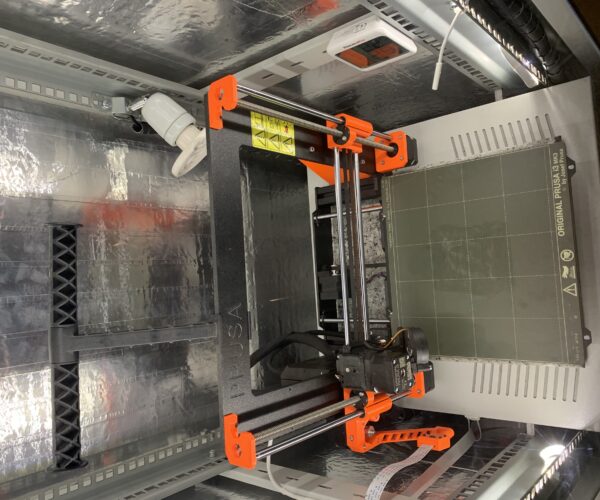

Have an enclosure (old computer server rack) and as its large have added a 150W ceramic bulb. Pre-heated bed and had bulb going only about 10 mins before print, ambient temp was 32C, I probably should have waited a bit longer and got it a fair bit hotter.

Problems - slight lift on left side of bar on the F but nothing you can really see afterwards and I guess running slightly hotter ambient would help that and maybe increasing the bed temp 5 degrees for first layer?

The top surface of the model is graduated and is supposed to be smooth but you can clearly see print lines and blobs formed on edges of layers. The gradients aren't very obvious but the same model does different sizes and much more pronounced in bigger scale.

Would likely improve top layers, probably with smaller layer height but not sure how difficult that will be to print so started with an easier option, also have a 0.25mm nozzle I haven't tried yet. Can give both options a go but wondering if that might be too problematic.

Also I plan on light prep followed by acetone smoothing so it'll be interesting to see how that turns out.

Thanks in advance.

PS. I wish Prusa would upgrade this forum so you can see more of what you are typing and photos didn't always get inserted as squares 😆

RE: First ABS print

As to the forum you'll get used to it, it's worse then you know relative to features your used to in other forums.

As for your first ABS print it looks OK for a first ABS print, your layers look as you would expect for a print this scale in 0.2 layer height, as for the curling look into an enclosure for printing ABS , even a temporary one will do the trick. the higher you go the harder it gets ; )

nice work so far keep playing, and have fun with it, even when it doesn't go like you want it to : )

The Filament Whisperer

RE: First ABS print

As to the forum you'll get used to it, it's worse then you know relative to features your used to in other forums.

As for your first ABS print it looks OK for a first ABS print, your layers look as you would expect for a print this scale in 0.2 layer height, as for the curling look into an enclosure for printing ABS , even a temporary one will do the trick. the higher you go the harder it gets ; )

nice work so far keep playing, and have fun with it, even when it doesn't go like you want it to : )

Yes, its so hopeless in comparison to a car forum I'm on, otherwise I probably wouldn't have thought too much about it.

Thanks, will have a go tomorrow with smaller layer heights.

I've got plans for a fairly tall print but thought I'd start on the smaller ones first to get the feel for it.

I've got an enclosure but its quite big and the printer is set fairly low in the cabinet as I'm hoping to get the MMU and spools in the top so its a lot of space to heat. I added 25mm PIR insulation which brought the temp up a good 8 degrees. Also insulated the bottom of the shelf so I can keep the PSU inside the cabinet and so far that doesn't get much above room temperature but I can always mount externally.

I was a bit keen tonight as I read people were printing at low to mid 30s but if I leave the ceramic bulb and bed on for longer it gets a fair bit hotter and I'm thinking if the taller print is unsuccessful I can always add another heat bulb.

Also I ran with the fans in the top of the cabinet on extracting out of the window, it doesn't seem to cause a draft nor particularly cool it down a great deal but I could perhaps just block the large gap in the top of the door opening and switch that off it needed.

Plenty of options and things to adjust once I get into more prints. I'm thinking with the smoothing advantage (assuming that goes smoothly) that ABS might be the way forward.

RE: First ABS print

If you don't have an enclosure, I recommend using the draft shield for all ABS prints, even those that don't seem to be that tall. It will help reduce any cool drafts that might hit the lowest layers. Both PS and Cura have this as an option.

For the item above, I would suggest using a layer height lower than .2. .15 is my usual for small ABS objects.

I've found that the Layerneer Bed Weld works quite well with ABS, both as a release agent, and to help prevent warping.

For ABS I recommend preheating and letting the printer stabilize for maybe 10-15 minutes before launching the print. You did say you let it cool to almost room temperature before removing, which is a good practice. Please avoid the temptation to use metal tools to 'persuade' an ABS print to release. With a release agent, they should release with some flexing when the sheet cools.

RE: First ABS print

@jsw

Draft shields will work for most prints. I prefer an enclosure because it reduces some of the fumes. Each enclosure has a hepa filter also.

--------------------

Chuck H

3D Printer Review Blog

RE: First ABS print

I would suggest that you make sure you have the ability to regulate the ambient heat in your enclosure, the idea of the enclosure is to ensure a consistent/equal heat distribution around the print during printing and a regulated\controlled dissipation of the heat upon cooling to help reduce shrinking and curling, In our stratasys printers the filament is kept warm and the print area is regulated during printing with a controlled cool down cycle at the end. At home I will do something similar by leaving my bed temp up and gradually over time reducing it until its about 40c and then just letting it cool down unpowerd I would love to have a G-code to handle this. but even this helps a lot with warping on tall thin parts.

The Filament Whisperer

RE: First ABS print

@swiss_cheese

Most filaments do not require perfect heat distribution. They do require warmer temps and a lack of drafts.

--------------------

Chuck H

3D Printer Review Blog

RE: First ABS print

Thanks for all the replies, I'm glad I posted as its confirmed some of what I was thinking and given me some good ideas too.

I've got the ceramic bulb on a thermostat but I didn't initially give it long enough to pre-warm and being a small print it didn't hit the max temp, plus I had the fans running all the time, something I can further test and adjust.

I added a switch for the fans to the top of the enclosure so can be operated without opening the door but I could easily add a thermostat for those too if cooling is necessary. Another idea I have is to make diverters over the fan inputs to help reduce drafts should this be problem for taller prints.

I'll definitely try the slow cooling process @swiss_cheese, easy to set the bed temperature in steps manually using the Octodash. Thanks to the posts in the dominos thread I've been encouraged to look at g-code. I'll start by adding some g-code to step down the bed temperature in a custom Octodash button perhaps using a G4 Dwell between temp settings and if successful I could put it in the slicer End g-code for a specific ABS printer profile.

Thanks again.