Filament

Duramic Silver PETG is a good filament. It is not the only one. I have also used the following:

- Hatchbox Silver PETG

- Inland Silver PETG

- Matterhacker Silver PETG

- eSun Silver PETG

- Push Plastics Silver PETG

My favorite is Duramic or Push Plastics but you get good results with all of the ones listed above. I hope Prusa releases a silver Prusament.

--------------------

Chuck H

3D Printer Review Blog

silver

I've been happy with the duramic silver. I have a few other spools of there stuff. Pretty good results with it.

Thank you

Thank you for your detailed reply. I appreciate it

Nice work

Thank you for doing this. What extrusion multiplier are you using for this print?

Also, your ironing setting looks very nice, are you using the default settings?

here's the thing in duramic3d silver PETG. I hadn't noticed the small imperfection when I printed in white.

I mean honestly this should be ok. I'm sure swiss_cheese could get this across the finish line lol

RE: attempt4

I've attached the most recent version. It's the version used to print that in duramic silver.

It's not perfect. This is only different from attempt 3 in temp. I had transposed the first layer temp as 254 when I meant to 245. Again, this printer has a steel nozzle so that temp is a little higher than it would be for brass.

Thank you for doing this. What extrusion multiplier are you using for this print?

Also, your ironing setting looks very nice, are you using the default settings?

here's the thing in duramic3d silver PETG. I hadn't noticed the small imperfection when I printed in white.

I mean honestly this should be ok. I'm sure swiss_cheese could get this across the finish line lol

bed temp

Thank you.

I understand the first layer bed temp is important but why does it need to go up to 90C for other layers?

Do you know the rational behind it?

default for prusament

the bump to 90 is the default for prusament petg. I think you could probably do 85 for all and be fine.

Thank you.

I understand the first layer bed temp is important but why does it need to go up to 90C for other layers?

Do you know the rational behind it?

shell thickness

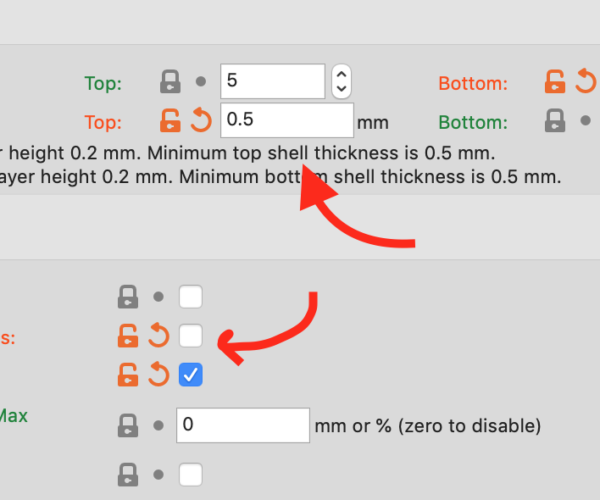

I had to mess with those to eliminate the gaps in the sliced model. go back to your original and slice it. look at each layer in in the sliced output. you'll see gaps. I toyed around with extrusion widths and the shell thickness to eliminate the gaps.

Also, can you please explain the reason behind reducing the minimum shell thickness to 0.5mm?

and why the ensure vertical shall thickness is not checked?

Slice of bread

Got it. Well done mate. I really appreciate your effort.

I had to mess with those to eliminate the gaps in the sliced model. go back to your original and slice it. look at each layer in in the sliced output. you'll see gaps. I toyed around with extrusion widths and the shell thickness to eliminate the gaps.

Also, can you please explain the reason behind reducing the minimum shell thickness to 0.5mm?

and why the ensure vertical shall thickness is not checked?

RE: ESUN PETG Print Settings

I know this is an old thread - but I still wanted to express my gratitude. Thanks to you, I notice that Prusa changed their extrusion multiplier to 1.0, over the last year, meaning that printing quality got heavily compromised on my older MK3S+. Thank you 🙂