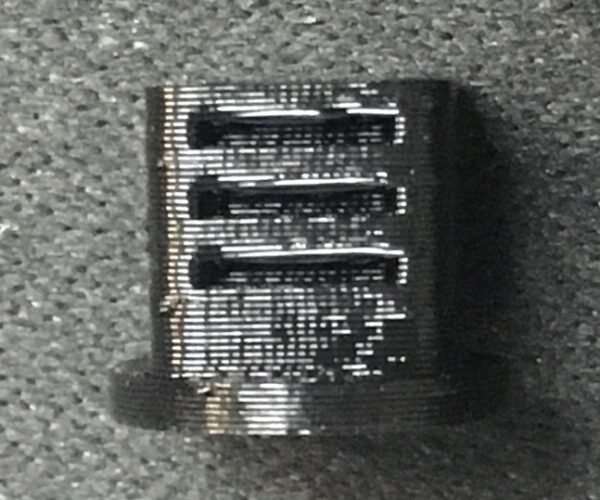

Drooping on measly 5mm bridge with PETG

I know PETG is notorious for its bad bridging, but I'm surprised that even small bridges are such a challenge. This is the best I've been able to do by increasing fan speed to 100%, slowing way down (bridges at 20mm/s) , detect bridging perimeters checked, and increasing overlap to 50%.

I'm not sure if there is much left to try, but any help would be appreciated. I have a small insert that needs to go in the slot so the drooping is challenging. Using Atomic PETG, but same thing occurs with AmazonBasics. 3mf is attached. Thanks in advance.

RE: Drooping on measly 5mm bridge with PETG

Have you tried with fan at 100% and Detect Bridging Perimeters OFF so the printer treats the bridges as normal perimeters??

RE: Drooping on measly 5mm bridge with PETG

Change your bridging angle to 90 degrees

RE: Drooping on measly 5mm bridge with PETG

You butchered this profile, changing things when you didn't understand what they do, and that's why your PETG isn't printing well, PETG can bridge just fine. I printed your part with no issues what so ever using a properly adjusted profile.

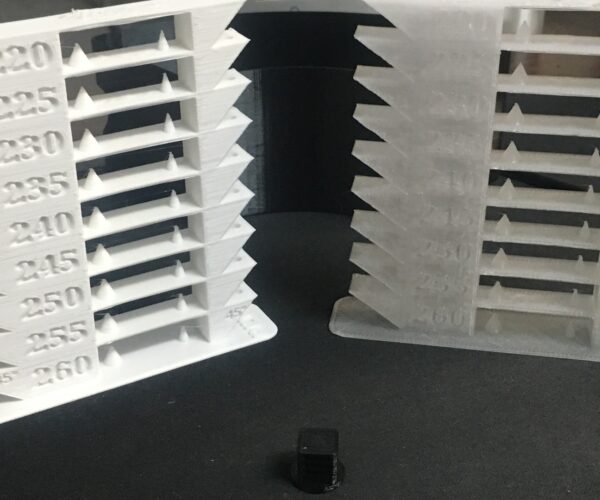

These temp towers are both PETG and the bridging you see on them is almost 30mm (more then an inch),

and I've bridged PETG much farther then that.

This is a profile I designed for Overture PETG, it is very close to Amazon basic as filaments go. I'm not familiar with Atomic but this may help you, and take some time to learn what the settings do play, play, and play some more. change one thing at a time, see the result is, then move on and change something else.

Main_Swiss.3mf

Good Luck, Have fun

Swiss_Cheese

The Filament Whisperer

RE: Drooping on measly 5mm bridge with PETG

@swiss_cheese

How on earth did you get such clean temp towers! Mine have so much string you could ... and now I can't think of a thing you could do if you had a lot of string.

RE: Drooping on measly 5mm bridge with PETG

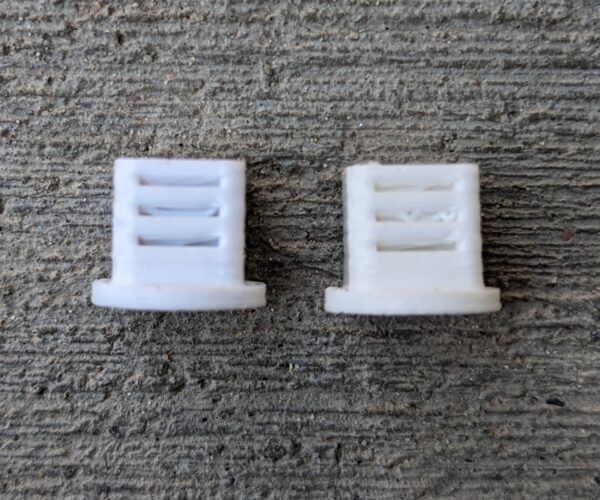

Thanks all. I was able to get a better bridge by turning off detect bridging perimeters and shortening the bridge by .5mm. It's not ideal but I can make it work if I need too--I sort of assumed 'detect bridging perimeters' could only help. Wasn't able to improve results by changing the bridging angle though, I'd previously tried 45 as well.

@swiss_cheese really appreciate you testing the print and sending over your profile. You're right about my profile.. admittedly it ended up being sort of a hodge podge of recommendations from other posts I could find out there (though I mostly tested them one at a time). Not sure why, but my results with your 3mf were close to what I initially got with the generic PETG profile. Atomic is on the left and AmazonBasics is on the right. Is it possible this just comes down to filament brand? Those temp towers are absolutely unreal!

RE: Drooping on measly 5mm bridge with PETG

@joe-5

This is why I often recommend users not change from defaults unless they themselves can predict the outcome. The profiles Prusa provides are one of the stronger reasons a Prusa printer is worth the minor premium over other printers.

RE: Drooping on measly 5mm bridge with PETG

@swiss_cheese

How on earth did you get such clean temp towers! Mine have so much string you could ... and now I can't think of a thing you could do if you had a lot of string.

I wasn't aware this was a problem for people, I adjust my filament profiles for every filament I use, you know, extrusion multiplier, retraction, so on and so forth and I only change the setting if needed. more often then not I only need to make 2 or 3 changes to the standard profiles to suit a new brand, and of course I keep my filaments dry.

Is it possible this just comes down to filament brand?

For certain different Brads act differently, and require potentially different profile adjustments, with that said I haven't come across very many that where so awful that I couldn't adjust them into submission, I think with time and experience you get a feel for it.

Regards

Swiss_Cheese

Filament whisperer 🤣

The Filament Whisperer

RE: Drooping on measly 5mm bridge with PETG

As a side note - each and every temperature tower I've printed I see zero change top to bottom; and that's after a line by line search to ensure I've 1) set the temperature that layer should be at; and 2) waited for the extruder to heat to said temp before extruding. Damned frustrating to see a pristine tower like yours. Gratz for having "the knack" ... lol.

RE: Drooping on measly 5mm bridge with PETG

@tim-2

I don't do temp towers anymore unless I see issues with a filament. Seems like these days most (quality) filaments perform equally well over a wide range.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Drooping on measly 5mm bridge with PETG

@swiss_cheese

I don't suppose you have a suitably tweaked profile for Prusament PETG?

Do you find filament colour affects quality?

Do you find any structural change related to temperature on your temp towers, layer-layer bond etc.

I take note of your comments re. dry filament, think I'm gonna have to get a dryer.

RE: Drooping on measly 5mm bridge with PETG

@towlerg

Dry filament is a must. Even PLA is temperamental that way, I have some that gets extremely brittle as it absorbs moisture. If the filament breaks as I unweave it from the spool, I know printing will be fun and I throw it in my food dryer for a few hours.

Plus, a drier was a life changing investment: it allowed me to get into making jerky. Yum.

RE: Drooping on measly 5mm bridge with PETG

@swiss_cheese

I don't suppose you have a suitably tweaked profile for Prusament PETG?

Do you find filament colour affects quality?

Do you find any structural change related to temperature on your temp towers, layer-layer bond etc.

I take note of your comments re. dry filament, think I'm gonna have to get a dryer.

@towlerg

My answers are in the order you asked the questions

I do, however I don't just have 1 I have 4, and that's because, for example "Carmine Red" doesn't print exactly like "Prusa Orange" but there is another deeper reason. the whole reason I even print temp towers for each filament is that it shows me how the filament is going to react/print at a certain temp and at the specified "layer height"for that print in a variety of situations, if you look at the back of the temp tower that I used in the example up top you would see several other feature types also affected by temperature, layer height & "extrusion width" etc,,.. I use these to gauge how I might print a model with certain types of features and heat changes how these form. I may see that on my white PETG tower I had the least amount of stringing from 225 to 235, but the best bridging was from 245 to 250 if you turn he tower around you might notice that the best bridging off an overhang was 230 to 235. I'm trying to keep this short because I'm getting the stink eye from my woman I'm supposed to be paying attention to her, and I could write a paper on this.

Yes color can affect the print, hands down, I've seen this multiple times in my experience. it varies brand to brand, but it's not really a game changer.

yes temp can effect structure and bonding of layers and bridging and overhangs yes for sure it matters and is impotent to find the right temperature to meet your models need. I find that their is a good working range for structure. Ill use the white tower as an example again.

I already knew not to print this filament at 265C so I started at 260 and moved up the result showed me that at 225-220 I started to loose what I consider to be good cohesion of the layers and it showed first to me in the bridging and then in the wall smoothness and ultimately in the top where it was pulling itself and tips of overhangs curled.

I would liked to have said more in more detail but I have to go, will be back tonight, sorry for all the typos.

Enjoy

Swiss_Cheese

The Filament Whisperer

RE: Drooping on measly 5mm bridge with PETG

Thanks for such detailed info, hope you aren't sleeping on the couch ; )

I'd really appreciate it if sometime if you could post those profiles and your temp tower.

It would be great if some day you could list the slicer parameters that you tweak and the logic behind that when faced with a new material.

I am embarrassed to say just how bad my temp towers are compared to yours, it makes me realize just how much I have to learn.

I'm not sure how you could enumerate this but just how important is it to dry Prusament PETG.

RE: Drooping on measly 5mm bridge with PETG

@swish_cheese @tim-2 I may leave with may tail between my legs on this one, but after the discussion about dry filament I'm wondering if this could be the problem. I live in a very dry area (avg humidity is 20-30%) and have never had problems with stringing, so I haven't thought about trying to get it even dryer before I print. What would the two of you say? Will a dehydrator add any incremental benefits given my already low ambient humidity? Could it be why swiss is printing god-tier bridges with PETG and my are decided less god-tier even though it's the same profile? If so I may have to pickup a food dehydrator (unless there is a better solution)..

RE: Drooping on measly 5mm bridge with PETG

@joe-5

I live in an area that is relatively dry, too. But, I just pulled out a roll of blue filament that sat through winter in a plastic bag with desiccant - but the bag wasn't sealed (argh). The filament is so brittle it snapped trying to pull the end from the spool. It didn't steam when I printed it, but was making the occasional popping sound you'll find videos of. Other spools that have done that were 'refreshed' and made less brittle by a few hours in the dryer. Print quality was also a bit down, and that spool is going into the dry today. Water absorption is generally not an issue for PLA, yet, here it is.

I'm more concerned with other plastics that literally suck up moisture - and why I got the dehydrator. Nylon gains weight simply sitting on the printer during a print. So I don't even try. Those dry boxes are probably worth their cost if you are printing Nylon routinely. PETG, PC, somewhere in the middle.

For $100 you can get a dehydrator (the cost of 3 spools of spendy filament), and you can eliminate a variable.

Though if you look at photo's of Prusa's filament wall - and many print shops - spools are left out in the open for all to see. So YmmV.

RE: Drooping on measly 5mm bridge with PETG

I had very few occasions where I felt I had to dry filament but when I did I put it in the oven at 65 degrees C ( 150 F) for 4 to 6 hours. I'll let the oven sit for 10 minutes or so at target temp before putting the spools in, in case it overshoots.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Drooping on measly 5mm bridge with PETG

@tim-2

Is there a dehydrator you would recommend?

RE: Drooping on measly 5mm bridge with PETG

@joe-5

There are a couple threads with reviews. Temp range and accuracy were topics.

RE: Drooping on measly 5mm bridge with PETG

@towlerg

I have found that drying filament makes a big difference on many fronts, I live on an island in California, however our humidity most of the year is in the 30's sometimes the RH falls forward to the 50's so it's not that bad where I live, but the filaments absorb moisture from the air, and then its locked in even the "so called" hydrophobic filaments, (PETG as my main example & PLA as a secondary example) the only way to release that moisture is to heat the filament and then keep it in a very dry environment. a filament dehydrator works great for this, many folks build there own from food dehydrators and they seem to work well, I'm the kind of person that would love to have made my own but didn't have the time when I needed one. So, I bought a Printdry the original one, the round one that sits on your desk, and its been going for four years now. I was so happy with the first one that I bought the new one awhile ago the boxy one And it also works great but doesn't fit on the desk as well. that might answer Joe's question as well if your not looking to build your own I can recommend the Printdry system.

towlerg, I'd be happy to help you work on your filament profiles, however I think before that you should work on finding a way to make sure your filament is dry first so that can be eliminated as a variable,

@joe-5

(Joe, yes for sure you will benefit from a filament dryer.)

Hope this helps,

Swiss_Cheese

The Filament Whisperer