RE: Downloaded pay-STL for Airplane-wingtip How To Slice ?

Hi Guys,

strength if models is affected by layer height, some folk say that a wing, printed at a low layer height will look lovely but potentially have reduced strength because of the number of inter layer bonds... I don't print wings, so haven't played with the effects of layer height on inter layer bond strength. I also believe that printing a touch higher temperature can give better interlayer bond strength.

if the surface thickness of a panel; is 0.43mm and it's not being sliced because your default external perimeter width is 0.45mm, you could reduce your extrusion width to 0.43 or you could change your XY correction factor to say 0.02.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Downloaded pay-STL for Airplane-wingtip How To Slice ?

Once again Joan,

Thank you for your input, which I will try on some test-prints.

Printing flying-models is a challenge and mastered by the people of www.3DLabPrint.com

There are not many designer offering files for RC-Model airplanes. And as it shows, some designers are at a steep learning curve to also offer usable STL or Gcodes.

Have a nice weekend, stay healthy, happy printing, kindest regards,

Rick

RE: Downloaded pay-STL for Airplane-wingtip How To Slice ?

And to William-m51 . . Hi . .

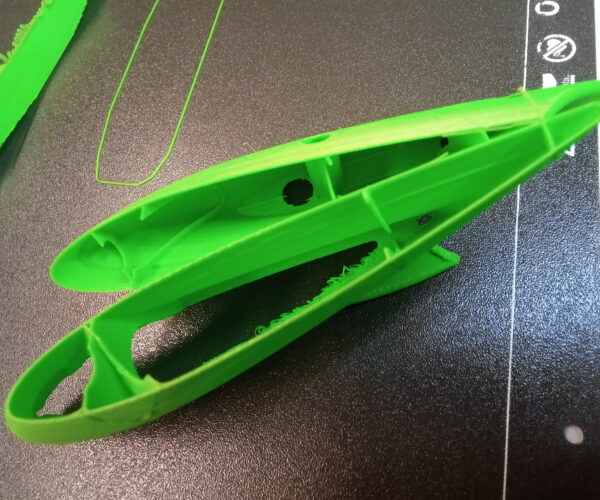

I printed your suggestion at parameters and at the pictures you can see the results. Same a you, I'm used to the file-quality provided by 3DLabPrint. To me they are the benchmark.

Not any negative thoughts about the designer of the parts I showed you, but these are far from "perfect".

I have found a 3D-printing specialist in a town nearby from my place in the Netherlands, who's willing to do a little study and experimenting to get descend results. With it I can give useable feedback to the original designer.

In due time, I'll keep you and Joan posted about the progress we'll make. (I hope hahaha)

Regards,

Rick