Decent bridging for layer supported by fins

Hi Everyone,

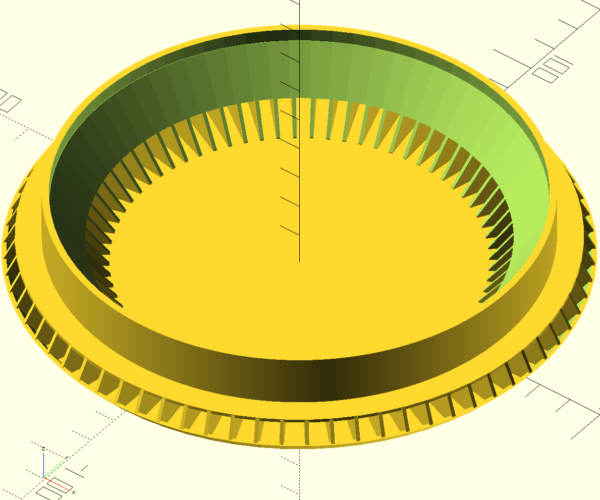

I am trying to print an intake cover as shown below. OpenSCAD source:

difference() {

union() {

cylinder(d=150,h=0.8,$fn=72);

difference() {

cylinder(d1=150,d2=157,h=4,$fn=72);

translate([0,0,-1]) cylinder(d1=147,d2=156,h=6,$fn=72);

}

for(i=[0:5:360]) { rotate([0,0,i-0.5]) translate([50,0,0]) {

rotate([90,0,0]) linear_extrude(1) { polygon([[0,0],[25,0],[28,4],[25,10],[0,10]]);} }

}

translate([0,0,9.8]) cylinder(d=135.8,h=15,$fn=400);

translate([0,0,9.2]) cylinder(d=150,h=1,$fn=72);

}

translate([0,0,1.1]) cylinder(d2=131.9,d1=100,h=20,$fn=72);

translate([0,0,21]) cylinder(d=132,h=10,$fn=72);

}

Can anyone tell me how to slice this with decent bridging (i.e. concentric rings) for the first cover layer? I could not convince PrusaSlicer to do this. Is there another slicer that performs better for this?

Kind regards,

Samuel

STL: https://www.dropbox.com/s/xinpult3fk403rp/intake.stl?dl=0

Best Answer by GKMAKEIT:

You could try something like this, I've never tried this so I'm shooting from the hip here. I don't know how the inner perimeter will do, might not stick.

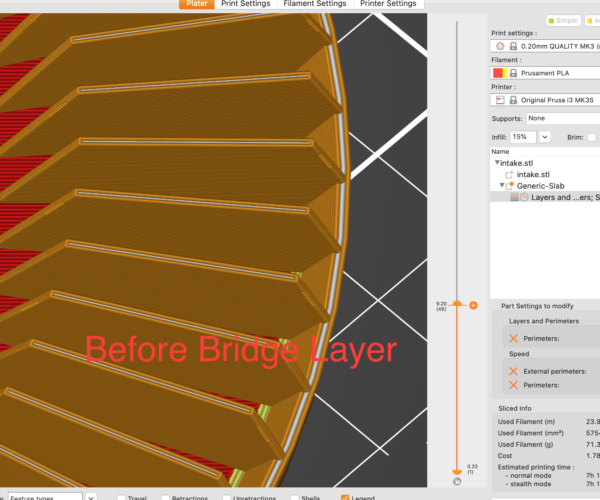

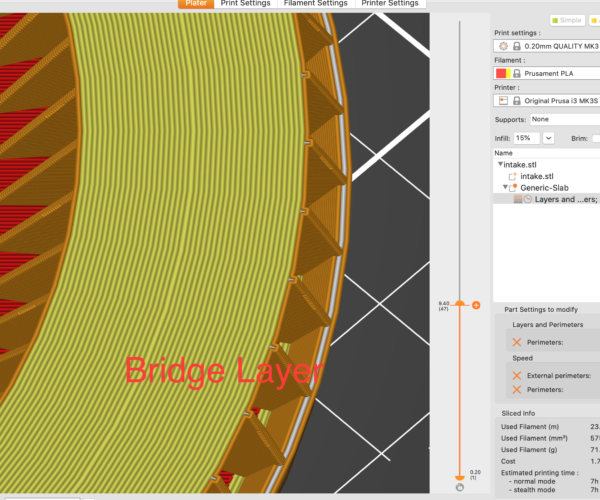

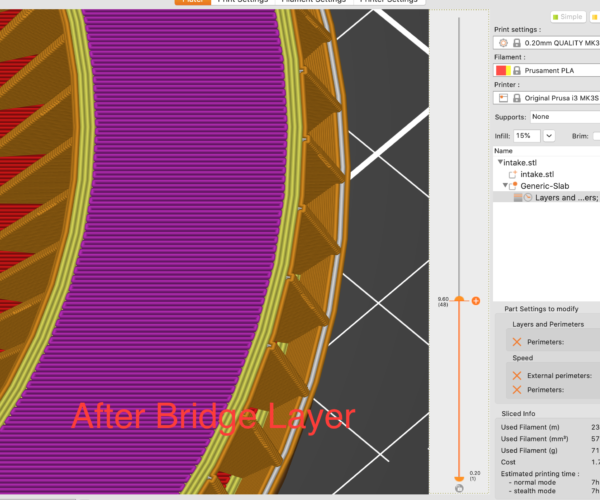

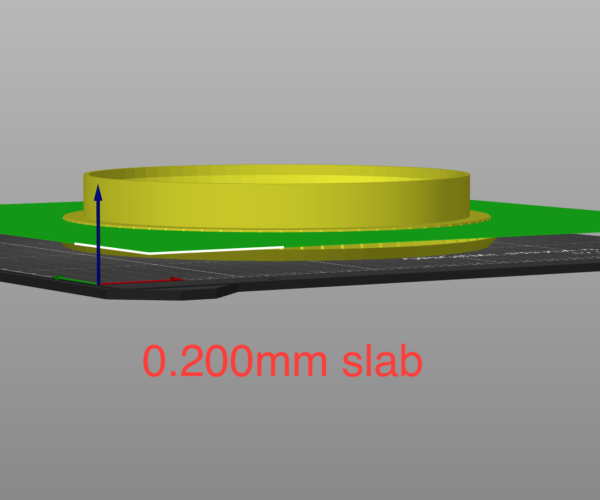

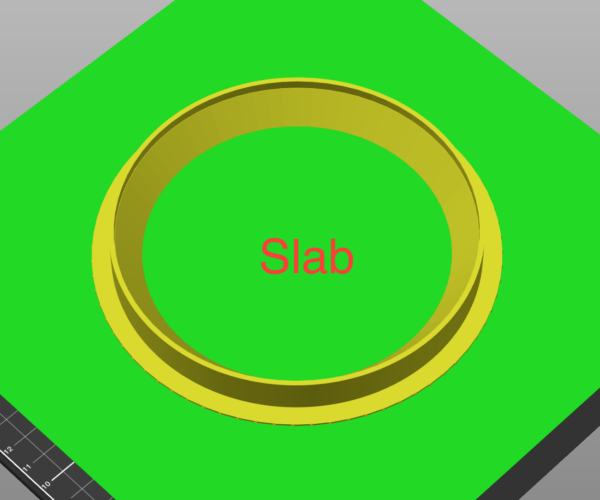

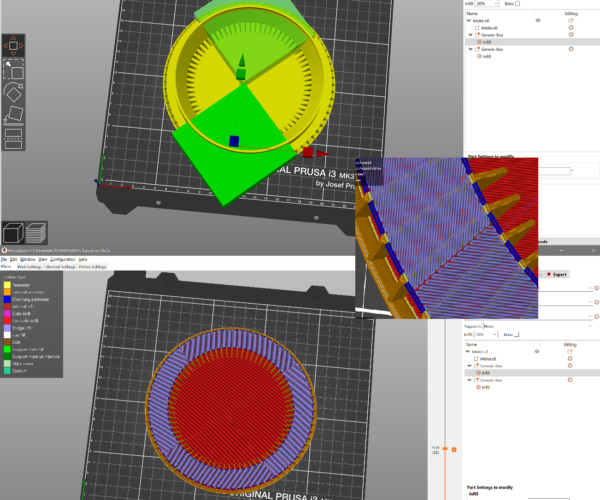

Add a "General slab".

Make it the thickness of your layer height for this example I used 0.200mm / layer.

Add setting "speed" to the slab and slow all perimeter down to bridging speed.

Add "Layers & Perimeters" to the slab and change perimeters to 23.

Move the bottom of the slab to the right height where the bridging layer would start.

I've attache a few pictures.

RE: Decent bridging for layer supported by fins

Conceptually, you can add modifiers to control bridging angle: you can subdivide as much as you desire. Here I did a simple quadrant to ensure bridges were at least somewhat across the shortest path. NOTE: I made no effort to ensure the intersections made sense (aligned with the part).

RE: Decent bridging for layer supported by fins

You could try something like this, I've never tried this so I'm shooting from the hip here. I don't know how the inner perimeter will do, might not stick.

Add a "General slab".

Make it the thickness of your layer height for this example I used 0.200mm / layer.

Add setting "speed" to the slab and slow all perimeter down to bridging speed.

Add "Layers & Perimeters" to the slab and change perimeters to 23.

Move the bottom of the slab to the right height where the bridging layer would start.

I've attache a few pictures.

RE: Decent bridging for layer supported by fins

@gkmakeit

now that is a really clever outside the box idea. I really hope that works. I suspect that the lower layer will become really messy as when it tries to print a curve with nothing on the bottom it will just sag down until it intersects with one of the fins. Bridging only works because it stretches a straight line of plastic between 2 points. But if a bit of mess is acceptable the fins might be close enough together to minimise this.

I’ve seen the printer do some things I thought would fail when it comes to overhangs though so if it were my project I’d certainly give it a try.

RE: Decent bridging for layer supported by fins

@neophyl

I know the bridging doesn't work on curves, but I'm hoping with the fins being so close it will pretty much just do a straight line. Hopeful get a good enough layer down to continue the print. I'm really curious myself to know if it works, I might try just printing that section.

RE: Decent bridging for layer supported by fins

This is a good case for concentric infill for bridges. Too bad it doesn't appear to be an option.

RE: Decent bridging for layer supported by fins

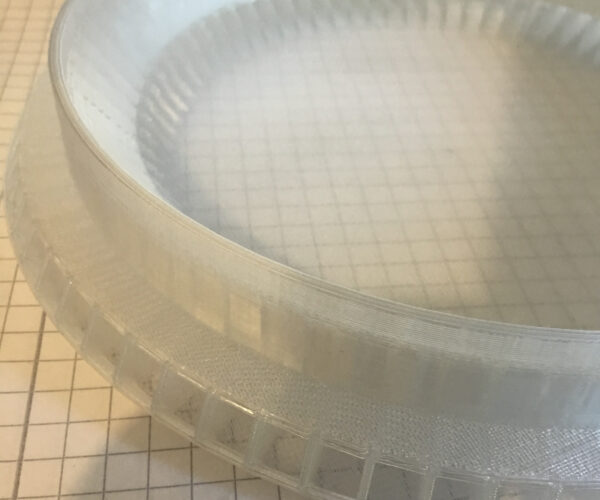

@gkmakeit Thanks for the neat idea/instructions. It worked very well as seen below. I manually changed flow using the tune menu for the bridge layer. Next time I have to remember to edit the gcode for flow and fan. It would be nice if these could be modified graphically as well. Maybe in a future version of PrusaSlicer. Per-layer controls for tunables should not be too hard to implement.

@neophyl I started 3D-printing with a Makerbot Thing-o-matic about 10 years ago. I have a good idea of what prints well and made the geometry to have straight lines between the fins. There are 72 fins supporting a cylinder of 72 sections. (They are pretty close too. I guess curves would also be OK.)

Thanks everyone for your time and interest.

Printed using transparent PET-G, 0.3mm layers, default settings except for the bridge layer with lower speed, all perimeters and manually tuned flow.

RE: Decent bridging for layer supported by fins

There's the insert custom gcode option at layer height available in the 2.2.0 alphas. Its sort of like the change colour at height (located in the same area) but it allows you to insert gcode instead. That should make it possible to tune things at certain heights.

That does look like it came out really really well though.

RE: Decent bridging for layer supported by fins

Some day with future firmware updates that might be a built in feature, until then we just have to get a little creative!

Glad it worked.