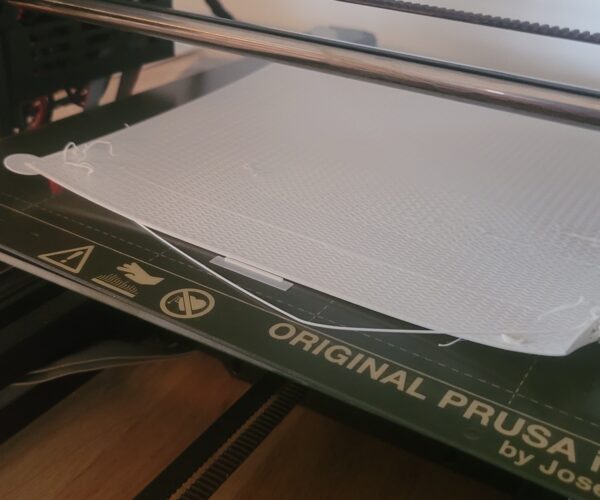

Curling from print bed on large print

I'm printing what's essentially a 7inx7in cube. The bottom layer eventually curls up. I tried heat for just the first layer, and heat off after maybe 1cm of height, also heat the whole time. This is Hatchbox PLA on 210c and 60c end/bed. I've heard as the higher layers cool it will pull the warmer lower layers inward which is why I tried to have the lower layers cool earlier, but it's just not working. I have the original double-sided steel sheet as the base. I've done glue stick and no glue stick, though it seems like the glue stick dries out too quickly with the long print time of first layer...or really dries out pretty quickly no matter what. If I could glue just ahead of it about to print that area I may be ok but that's really doing some work for something I'd think should already adhere.

Glue stick is usually used to *reduce* adhesion...

Get the print sheet thoroughly clean and show us your first layer Z calibration print on the print sheet. A picture of the bottom of a failed print might help too.

Your print is approaching the size where warping becomes an issue so you may be right in your diagnosis but lets get the foundation layer as good as possible first and see if that's enough.

Cheerio,

RE:

It's common for large box-shaped/rectangular objects to warp. Assuming Live Z is well calibrated and the steel sheet is clean (using hot water and fragrant-free dish washing soap), here are a few approaches that have worked for me:

* Slow down print speed.

* Add Mickey Mouse ears to the corners. You can add a cylindrical part in PrusaSlicer, maybe 10mm diameter, change height to single layer height, then place the part at the corner. Repeat for each corner.

* Add a brim around the model, 5 mm or more. Wider or 2 -layer high brims may be needed but may not work with the size of the model or may require being added in your CAD software.

* Use Layerneer Bed Weld https://www.amazon.com/Printer-Adhesive-Layerneer-Original-Filament/dp/B079984GV5 You only need a thin layer.

* If you have design control over your part and it's possible considering the intended use, you can try to round the edges and/or add holes to the base of the model.

* Combination of above. Usually, brim/ears does the job, or some Layerneer if needed, but large, rectangular objects can be a challenge.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Curling from print bed on large print

You can also try raising the bed temperature to 70C with larger models

regards Joan

clean the build plate, do a good live Z setup, I use 7x7 mesh bed levelling (available Via LCD Menu)

and print with the bed a bit hotter than normal.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE:

I considered ears on the corners, may do that. It's essentialy a large square on the bottom.

RE: Curling from print bed on large print

RE: Curling from print bed on large print

I've had no success printing PLA using any cleaning method other than Acetone, assuming the original smooth build plate. The first few prints when new were OK but as time went on adhesion became worse. I print PLA on one side and always clean with Acetone. I always print PETG and others on the flip side where bond beakers are required for those materials. On the PLA side, if I use IPA, 99%, the print will fail.

Also the 1st layer calibration is more sensitive for larger parts.

If, as shown, you don't get the 1st couple of layers well fixed securely, the rest will surely fail.

This works for me.

RE: Curling from print bed on large print

Ok I haven't tried acetone. It just seems like this is too big for the curling forces. I'll see if that works.

Use acetone sparingly. it will eventually damage even the smooth sheet.

Clean with IPA between prints.

At the first hint of a problem, use dishwashing detergent (Dawn/Fairy) and plenty of HOT water, rinse well and dry with a fresh paper towel. Handle by the edges only.

If that's not enough use acetone: once or twice a year at most.

And please show us the underside of a failed print.

Cheerio,

RE: Curling from print bed on large print

I ran into a phase where nothing would stick to my build plate printing with PLA, even on a freshly washed (Dawn and hot water) and acetone wiped smooth sheet. The solution for me was to build enclosure walls around my printer (I just used cardboard) and now adhesion is better than ever. There must have been a draft from a vent or something that was moving air past the print and the rapid cooling was causing prints to curl up. I would never print without a draft shield now.