RE: Corner gaps help

Very likely it's one of:

-an incorrect extrusion multiplier

- Incorrect filament diameter in slicer (interplay with the above)

-Miscalibrated K-value (linear advance) for the filament at its current temperature.

RE: Corner gaps help

@vintagepc

- Extrusion multiplier for three-perimeter, 0.7mm extrusion width is spot on at 1.93mm. A 0.6mm nozzle is installed.

- Filament diameter is set to 1.75 and my filament measurements are exactly 1.75

- The linear advance calibration results shown below (lines from bottom to top are valued 0 to 90 in increments of 10) indicate that K30 has the most consistent line width and that's what I have the custom g-code set to. Linear advance calibration g-code is attached. I'm using Matt's Hub method for calibration.

Anything I'm missing something here?

RE: Corner gaps help

gcode attached

RE: Corner gaps help

Extrusion multiplier is best set for a single-wall extrusion (i.e. 1 perimeter.) Multiple perimeters have some degree of overlap so they fuse together and give a different measurement than just n*extrusion width. I see the number you're looking at takes the theoretical overlap into account but this does not necessarily handle the volume being extruded, only the relative placement of the lines.

(For a visual example, add a 2mm x 20mm box to the print plate, slice with 2 perimeters at 0.5mm extrusion width and slice. You'll get 4 extrusion widths and some change in the form of gap fill.)

RE: Corner gaps help

If you've got all those things dialled in (and, importantly, your live Z value is good), then it's time to start looking at a few other settings - specifically, the infill/perimeter overlap percentage (which looks a little low in your print).

Then it's time to determine whether that is the start or end of the extrusion that is causing the gap.

If it's the start, look at the 'extra length on restart' parameter. Some filaments are more oozy/stringy than others and need a little extra to account for ooze loss.

If it's at the end of the extrusion, try turning off 'wipe before retract'. It should be unnecessary if your K-value is correctly set.

RE: Corner gaps help

@vintagepc

Thanks so much. I'm going to tackles these things on Tuesday and report back.

RE: Corner gaps help

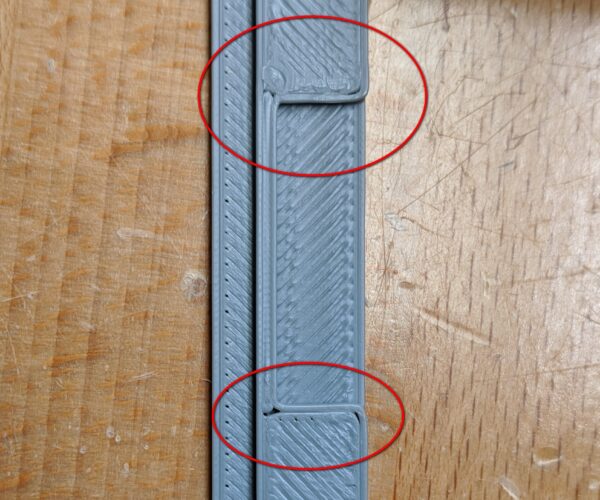

Sorry to necro this, but I am having the same issue. 0.6 mm nozzle, I've calibrated my esteps and flowrate with calipers similar to how the above user did (around 93% in cura and PS). It seems to happen when the extruder slows down to take a corner, it ends up underextruding severly. I have my K-factor calibrated to K = 0.09 for my machine, and do not have wipe before retract on. I've seen some success in making my line widths somewhere in the 0.68-0.75 range, rather than having them the size of the nozzle or the Prusa profile size of 0.68 or less. Please advise, and I can post complete settings and anything else you need.

RE: Corner gaps help

Don't use the Matt hub method, it's not working with LA1.5. Use https://www.prusaprinters.org/prints/39968-la15-k-factor-calibration and remember to change the gcode temp to match as in the instructions.

RE: Corner gaps help

Did you have any luck with improving this using linear advance? Recently been noticing this on some of my prints which I print a bit quicker. Now printing them out of the enclosure and had to up the temperature I print at. It's always at corners and if anything the prints are generally a touch over extruded but I don't mind that as they are functional prints.

But I notice this exact thing on the corners. It's on all 3 printers so would suspect g code rather than mechanical. I'll play with linear advance as new print temperature to see if I can improve. I had already calibrated my linear advance but not for new temperature!

Oh and Merry Christmas all!

RE: Corner gaps help

@edg-engineering-2

I think I just accepted these gaps and didn't get into troubleshooting it. If linear advance is the culprit I wonder if the new version, 1.5, provides any resolution.

RE: Corner gaps help

@chrischin

So Just finished some testing. Looking back at my pictures of my linear advance testing it seems i picked the most consistent line and hence have been using 0.05 for my LA (1.5).

Just took a slice of a section of the part i have been noticing the issue and as i said i have been printing hotter. But brought my LA down to 0.03 and the results are a lot lot better and i have almost eliminated it and that is just using LA with no other tweaks,

I may rerun the calibration at the correct temperature and see if i can see the difference.