Constant Underextrusion: Please help me recover my sanity after disaterous prints

I am at my absolute wits end trying to resolve this after 14 days of near perfect run time, which has spiraled into about a week of torment. I have photos of the failures and the successes that I can add if it helps. The first two weeks of printing is almost all uploaded at my Thingiverse profile: https://www.thingiverse.com/groovyz1k/makes

I have tried so many things that I had to type it out in bullet form, and I apologize in advance for the length and likely rambling.

The Beginning:

Easy build with one minor X-Axis layer shift identified, thanks to the tree frogs, and promptly fixed. 14 days of run time with no issue after.

Hatchbox PLA dialed in around 205C first layer and 195 following, eSun PLA+ all happy at 212C/208C. Both run successfully even at 100% speed.

Loaded and ran two successful prints with CC3D Gold Silk PLA

• 3rd print, Sir Flexington, ended with severe under extrusion on the top layers

Troubleshooting phase:

2. Heated nozzle to 260C, with filament removed, and cleaned with the included needle, no improvement

3. Replaced nozzle with 0.4mm hardened steel, following instructions, and retested at 10C higher print temp

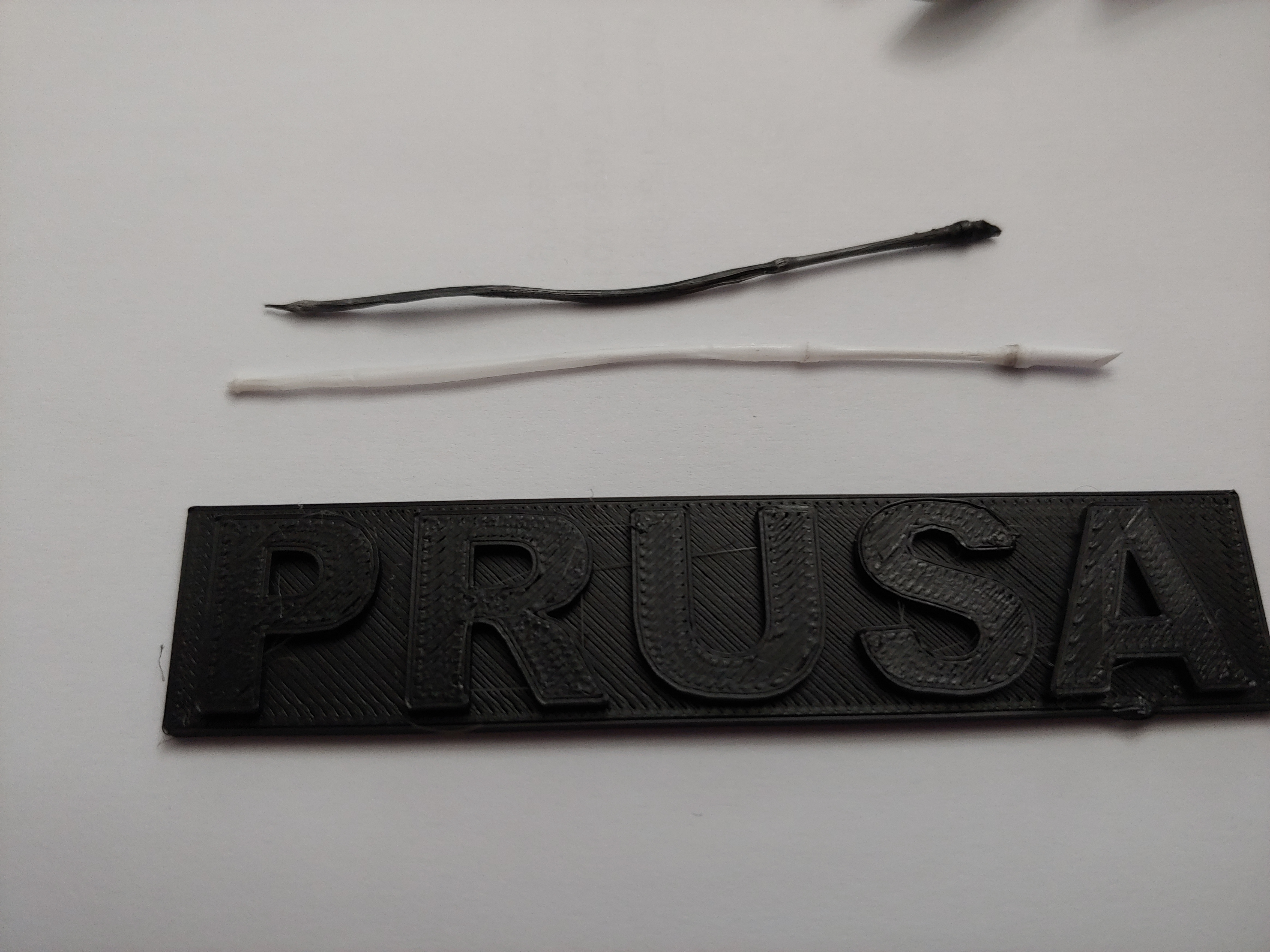

b. Horrible failure, with two color attempts at the PRUSA logo ending up a disaster of under extrusion

c. NOTE: Tensioner may have been too loose at this point, with the screw tip flush with top of nut

4. Cleaned original brass 0.4mm nozzle with heatgun and sewing needle, then included needle to clean tip area, then reinstalled to printer

b. Performed 3 cold pulls

c. Lowered print speed to 70%

d. Slight improvement but still under extruding

e. Tried multiple tensioner settings to the point of slight filament grinding and clicking and back

5. Reset tensioner to original build setting, with head flush with extruder plastic with no filament installed, and recleaned gears while verifying alignment

6. Printed 20mm Test Cube with eSun Purple at 218/214 and 70% print speed successfully

a. Under extrusion seemed very very minor and cube was dimensionally perfect.

7. Issue again, followed by cursing and lots of google/youtube

8. Completely removed Hot End from extruder, not a terrible process, and thoroughly looked it

a. PTFE tube looked good but was replaced with spare, verified seating and black locking ring position multiple times before reassembly

b. Reassembled at set tensioner to original build position, heated the assembly to 260C, replaced original brass (cleaned earlier) nozzle with brand new genuine E3D 0.4mm brass nozzle and retightened nozzle and heatsink which hot

c. Reran calibration wizard

d. Printed NASA logo, which I had printed many times already, with eSun PLA+ blue at 216/214 and 80% print speed and it looked great

e. Printed 10+ hour NASA “meatball” sphere logo, 218/214 at 70% for the back half and overnight at 60% for the more detailed front and it looked great

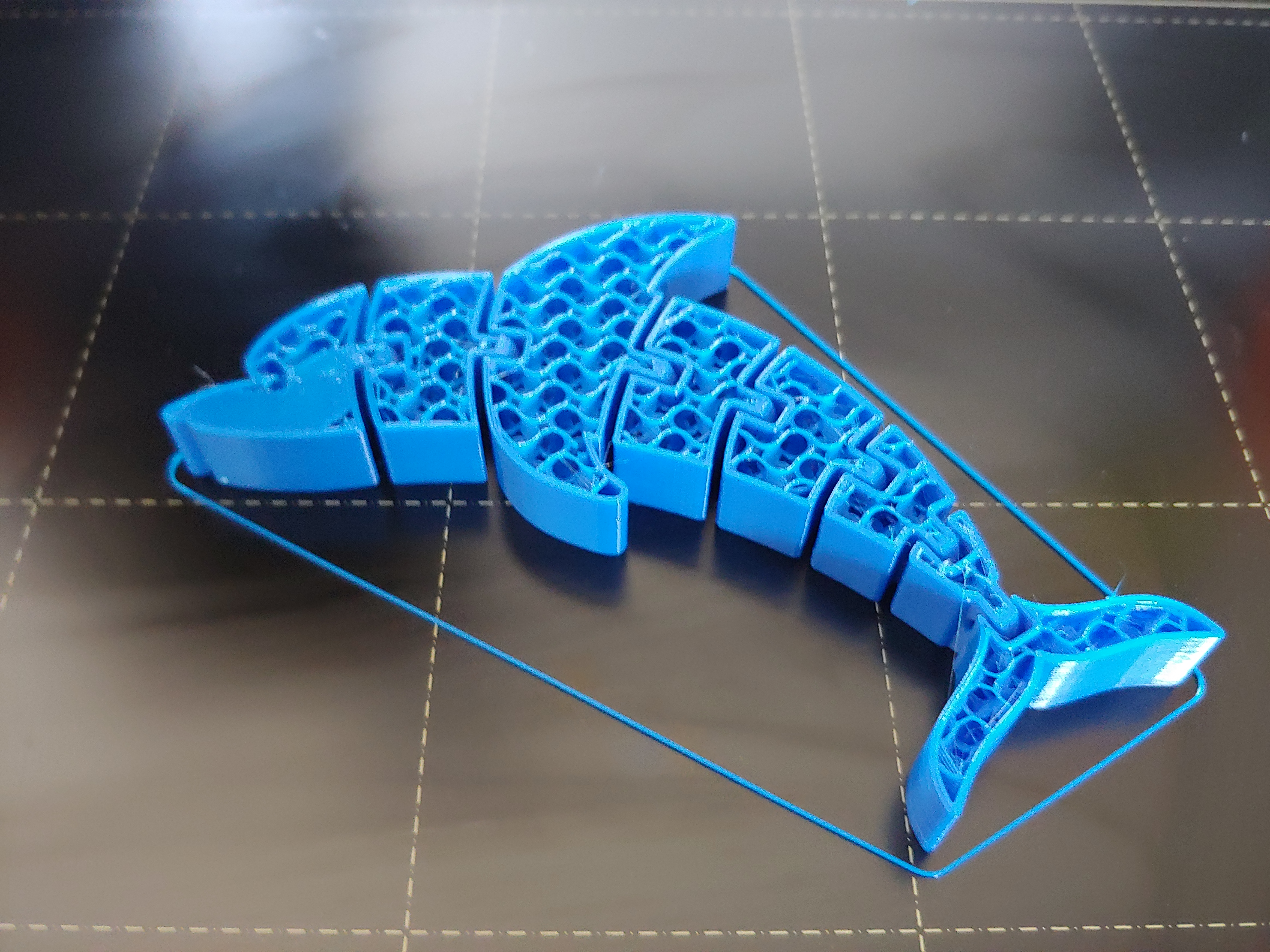

9. FLASHED TO 3.7.0 FIRMWARE. Attempted to print flexi-dolphin, which had been printed way back before the issues started, using the same filament and same settings as the NASA logo and got under extrusion

10. Double checked tensioner, ran PID calibration, and started a 3rd attempt

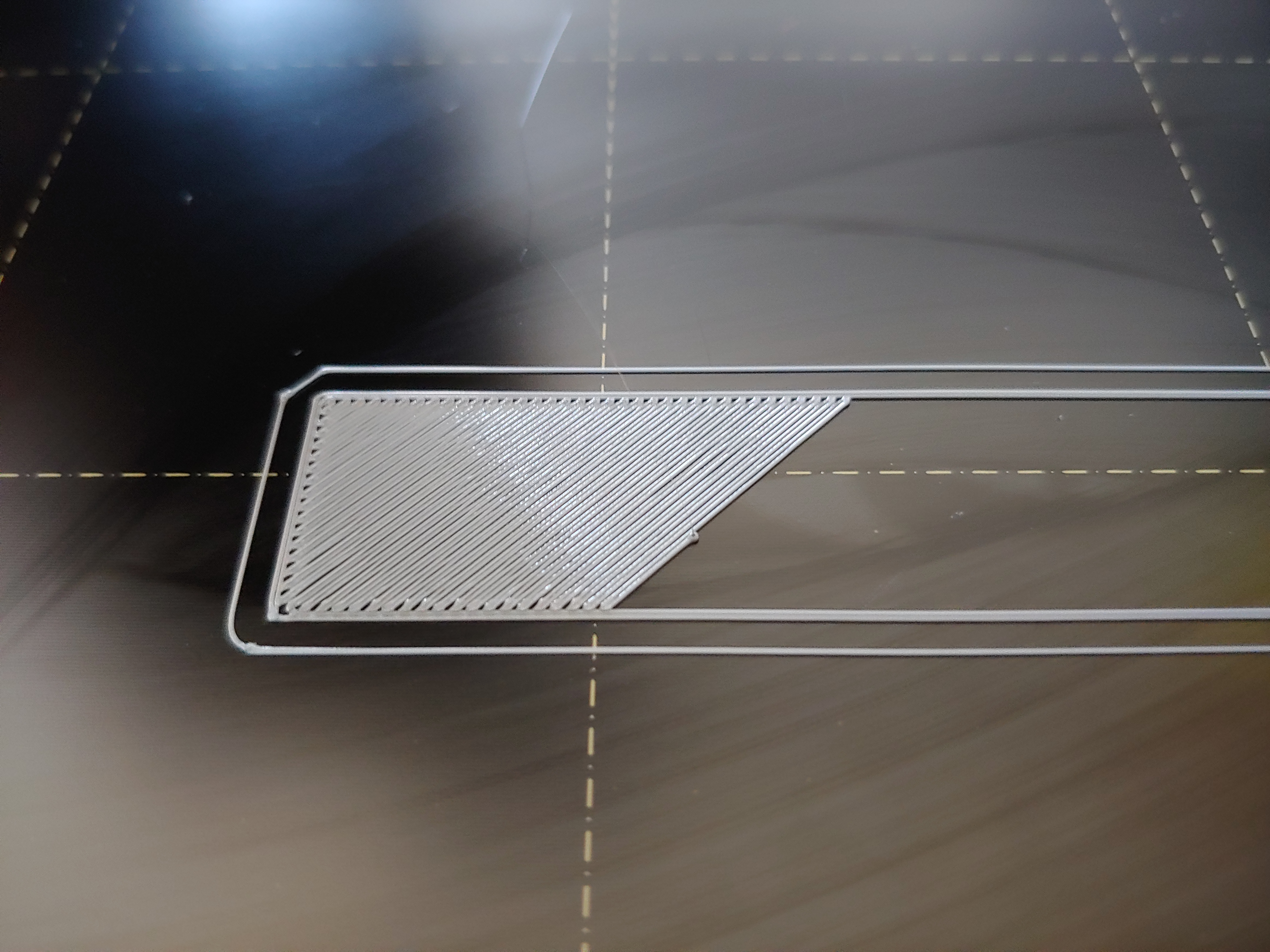

b. Checked print to find 90% of the first full top layer had no material at all and no material was being extruded

c. Cold pulled material in anger induced rage, but still per instructions

d. Hurled failed print across room followed with some profanity

11. Heated and cleaned nozzle with needle and found no resistance

12. Verified Bowden gear operation, alignment and cleanliness

13. Loaded as of yet unopened Prusa Silver PLA and attempted to print PRUSA logo using the stock provided GCODE, 70% speed

b. Cold pulled material

c. Verified bowden gear operation again, then stopped

All of this was done with a mix of Hatchbox PLA and different eSun PLA+ spools. Humidity at the printer is 10% thanks to living in Colorado and never got above 28%. Filament is kept in a Sterlite container with rubber seal and had the silica gel that shipped with the spools that was later replaced with Dry & Dry orange to green indicating silica that is still very orange. It was also all printed with the stock Slic3r data with the exception of temperature changes.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

live Z looks high to me, but you can wash the build plate with soap and water in the sink (dawn rules) but Z looks high but if it isn't sticking to the build plate the Z means almost nothing

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Its been sticking well for the most part. I tweaked the first layer Z a few times and I believe it is currently around -0.775. Each following layer shows the same extrusion when printing at 0.2mm, and the first layer is also set to 0.2mm. I had hoped that would fix it as well.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

set your live z with this method https://shop.prusa3d.com/forum/assembly-and-first-prints-troubleshooting-f62/life-adjust-z-my-way-t2981.html it is far better than the zig zag method in the firmware

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Worth a shot for sure. I'd definitely prefer a better Z-setting method, and am saving this one.

Would this have any impact on the following layer extrusion height? I still have to sort out the total extrusion failure.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

you can make a .2 high 50 mm test sheet. that works good. only bring up the stickiness because it bugged me until I learned the power of soap and water.

but that first layer picture looks too high. cant hurt to try 50 to 100 more. first layer shouldn't have gaps. try - 825/850.

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

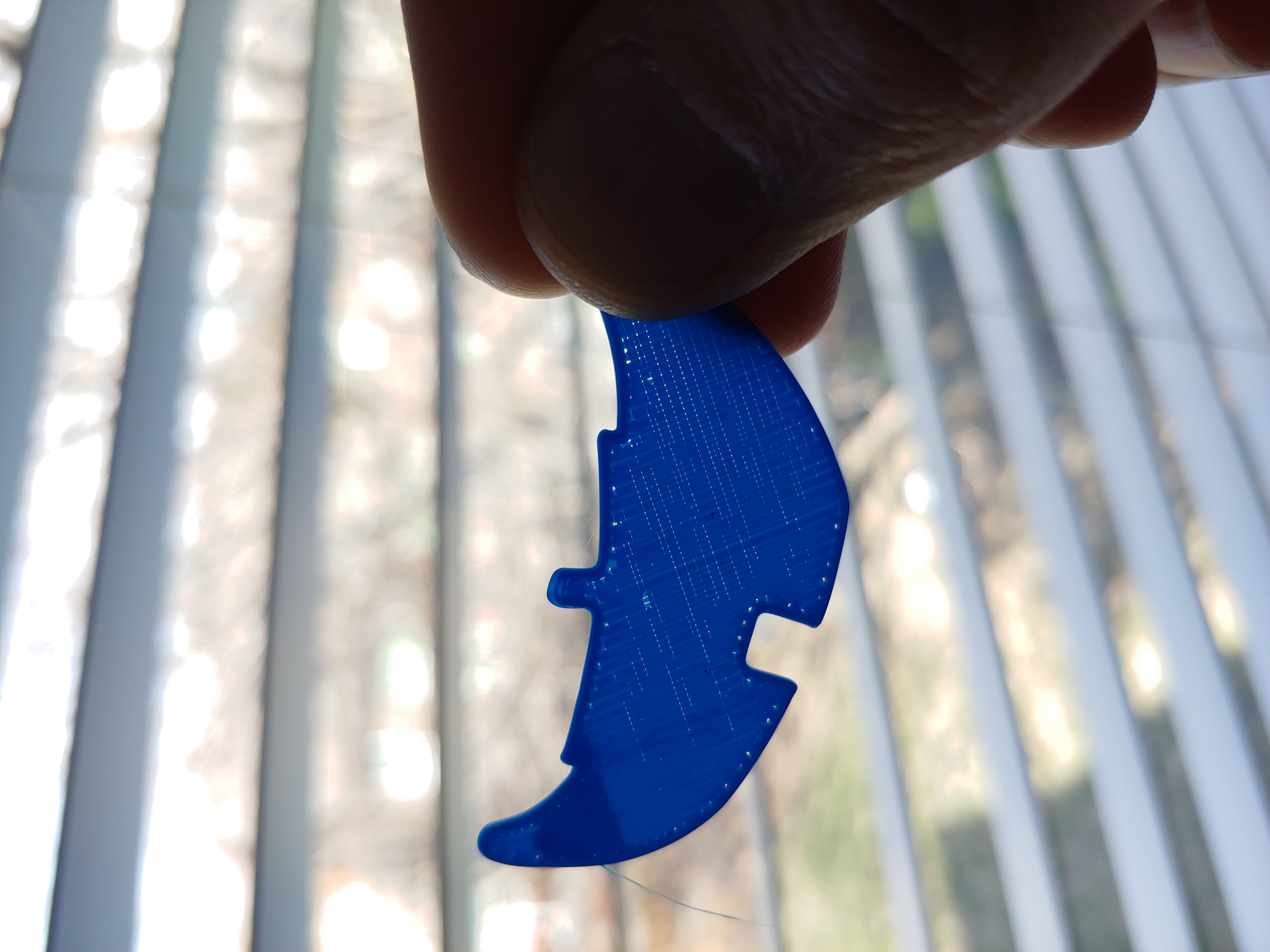

The first layer on the Prusa print is bad, but I can tune that and did before then. It seems to be a material flow issue. Attached is a photo of the dolphin where it stopped all material flow. I did not stop it halfway through the head layer, it was already long past that point with the extruder continuing movements but no material flow. Unfortunately it isn't a great photo, and I threw it across the room shortly after and haven't recovered it.

I have tweaked the Z adjustment on the first layer to the point where it looked perfect and beyond to the point where the nozzle is pushing material, and I am still getting missing under or in this case, no extrusion.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

maybe the filament is building backpressure.

did you calibrate (or check) the filament flow? (mark 100mm of filament then run the extruder 100mm and see how close it is)

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

maybe the filament is building backpressure.

did you calibrate (or check) the filament flow? (mark 100mm of filament then run the extruder 100mm and see how close it is)

That sounds like a good check. I'll definitely try it. It does seem like not enough filament is feeding, but I can't track it down to a mechanical issue, so it would be nice to know if the filament is indeed feeding less than it should.

Also adding some pictures of my cold pulls and how they look to see if they seem odd to anyone.

The latest pull, PRUSA silver PLA

Previous pulls:

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

ooo ooo I might know (raises hand).

.. maybe it has the wrong heatbreak. some people have had that happen

or gap between the nozzle and heatbreak.

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

I had the same thought on the nozzle gap. I took a look at everything when I pulled the extruder apart and it seemed good, and I have swapped nozzles twice since it started, being very careful to snug them up properly when hot. I was concerned the heat block may not have been properly snugged but it seems to be. I actually got out of bed around 1AM one night to check it! The heat break looked correct, and was working great for two weeks, but I am honestly close to getting a standard E3D heatbreak to install and try. It could be the wrong one for all I know.

I am honestly tempted to take it apart and reassemble it now just to see.

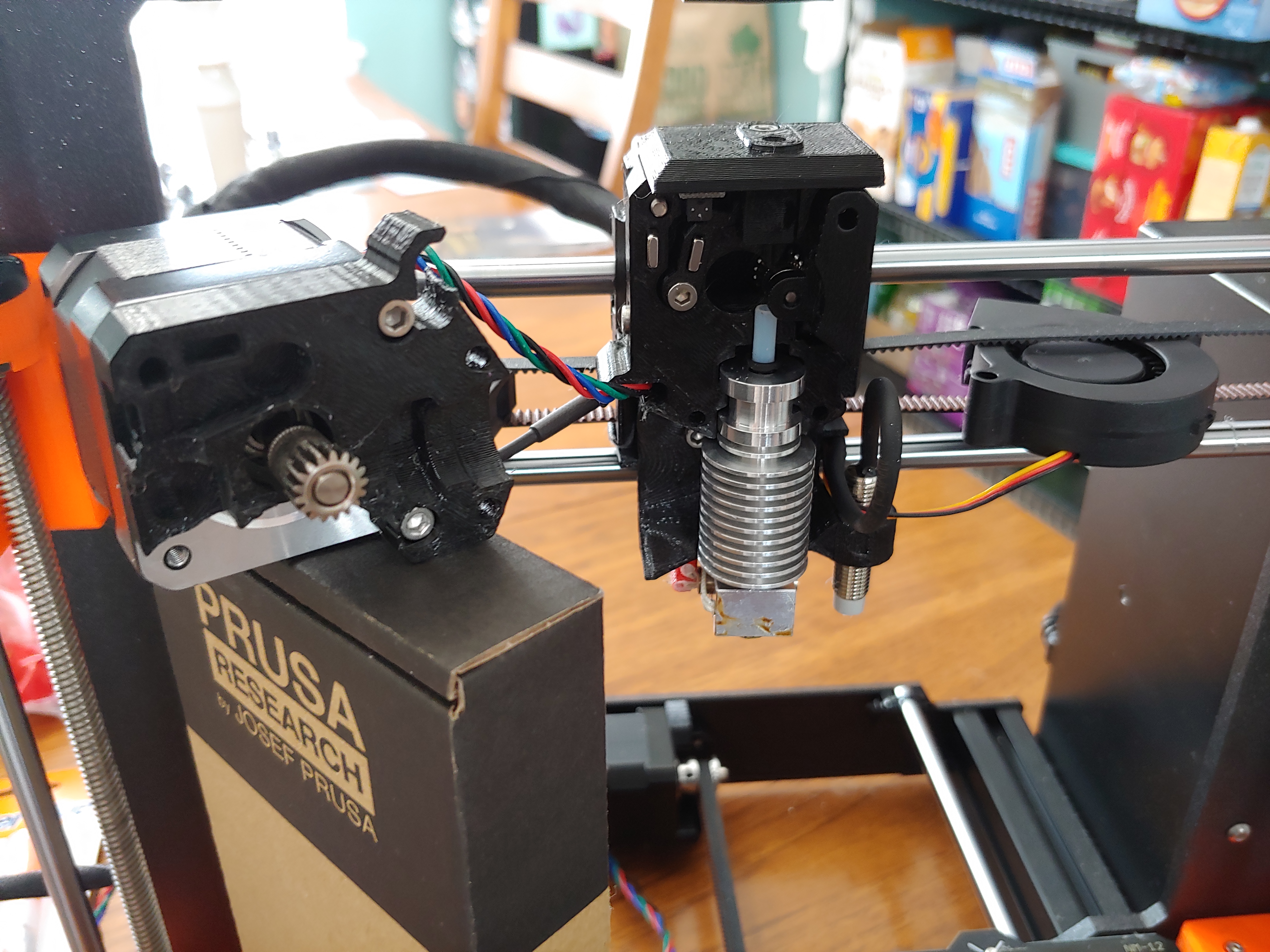

What it looked like opened:

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

This was the print before the trio of dolphins, and it looked great, which just adds to my confusion. These were printed at 0.1mm layer height though, so maybe it had less of an issue flowing enough material.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

as long as the nozzle has that small gap with the heater block, from the nozzle hitting the heat break.

I think joel the printing nerd did an video with proto pasta and they talked about the odd heat break thing ill look for it

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

Not sure if it helps, but attached are the settings for Slic3r for 0.2 Quality setting, which I believe are still fully stock and worked for weeks. I did print a blue NASA logo at 0.2mm layer height successfully right before I did the globe in the post above.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

as long as the nozzle has that small gap with the heater block, from the nozzle hitting the heat break.

I think joel the printing nerd did an video with proto pasta and they talked about the odd heat break thing ill look for it

It does have the gap. That was a helpful video as well to explain the unique PRUSA heat break.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

around 3:13 for the funky heat break thing.

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

4:36

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

maybe turning the temp up might help

I have a Prusa,therefore I research.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

maybe turning the temp up might help

When it was back to working form I found a 4-6C increase helped, however that was short lived. I am flashing firmware back to 3.6.0 now just to eliminate one more variable, since I did flash to 3.7.0 this morning before the three failed prints. It shouldn't make a difference, but worth a shot.

Re: Constant Underextrusion: Please help me recover my sanity after disaterous prints

hope it helps. trouble shooting a mk3 single is fun...compared to mmu added on top of it stuff 😀

it's sad.. at work I fix printers...at home for a hobby...I fix printers..

I have a Prusa,therefore I research.